Automotive Testing Lab Services in chennai

Automotive Testing Lab Services in India – Kiyo R&D Lab

In the fast-moving world of automotive manufacturing and supply chains, one thing remains constant: the need for trusted, high-quality testing services. Whether you’re developing a new EV component, refining a drivetrain module, or certifying interior trim for durability—working with a reliable partner matters. That’s where Automotive testing lab services in India – Kiyo R&D Lab come in.

At Kiyo R&D Lab, we understand that every component—from plastic moldings and elastomer seals to powertrain modules and complete assemblies—faces real-world stress. Our mission: to help you validate, verify and certify your products under conditions that mirror service life, regulatory demands and market expectations.

Why choose specialised automotive testing lab services?

Today’s vehicles are more complex than ever. With electrification, connectivity, lightweight materials, and harsher performance expectations, your testing partner must be up to the challenge:

- Durability demands: Components must survive mechanical shock, vibration, temperature swings, corrosion and fatigue.

- Regulatory compliance: Whether it’s EMI/EMC, functional safety, emissions (for ICE/hybrid), or onboard electronics, you need credible testing. For example, labs such as Intertek provide comprehensive environmental and electrical testing services for automotive parts and vehicles. Intertek+1

- Global supply-chain reach: If you’re supplying OEMs or Tier-1s who service global markets, your testing partner must follow recognised standards and offer actionable reports.

- Cost & time pressures: A late test report or re-work after failure may cost far more than the test itself. Early, accurate testing saves money.

In short: you need a partner who can deliver automotive testing lab services in India that are fast, reliable and aligned with your product lifecycle—and that’s where Kiyo R&D comes in.

What does Automotive Testing Lab Services at Kiyo R&D Lab include?

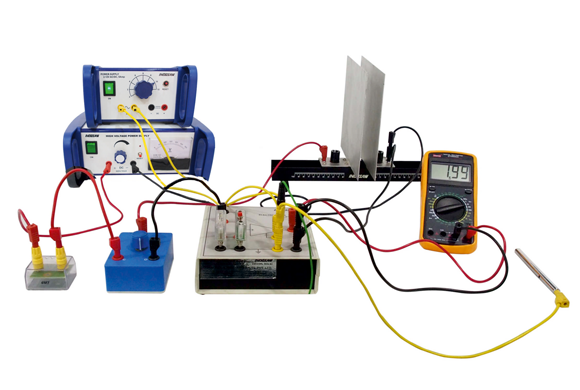

Working under the banner of “Automotive testing lab services in India – Kiyo R&D Lab”, we cover a broad spectrum of tests tailored for automotive components and systems. Typical services include:

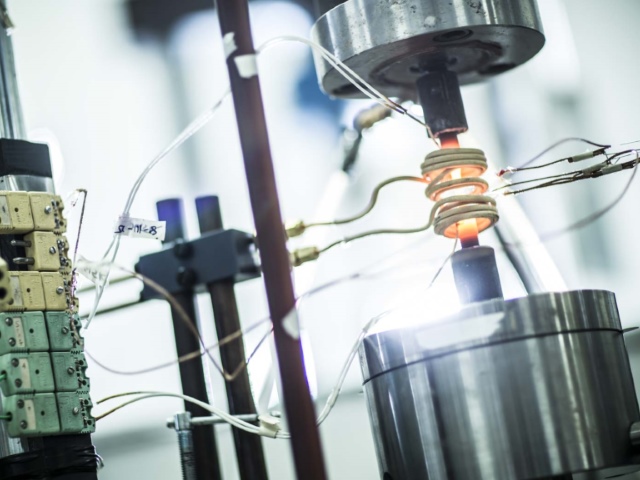

- Mechanical & durability testing: Fatigue, torsion, impact, vibration, shock.

- Material testing: Tensile, hardness, microstructure, metallurgical evaluation.

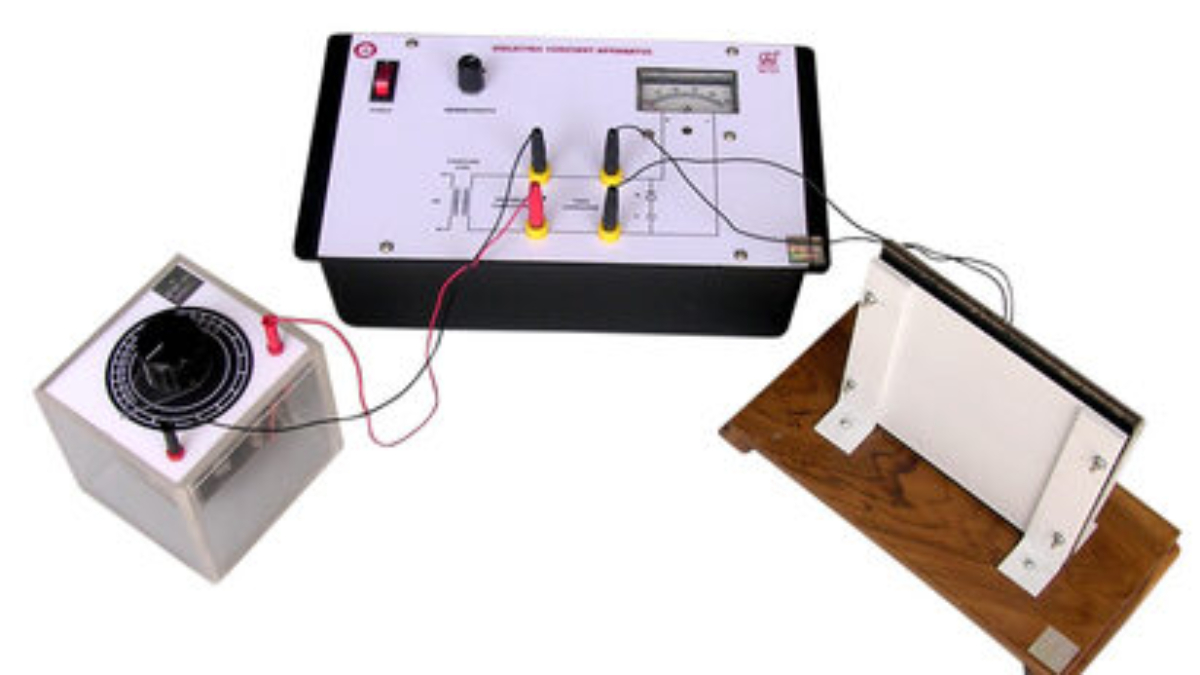

- Electrical / electronic testing: EMI/EMC, insulation, functional safety.

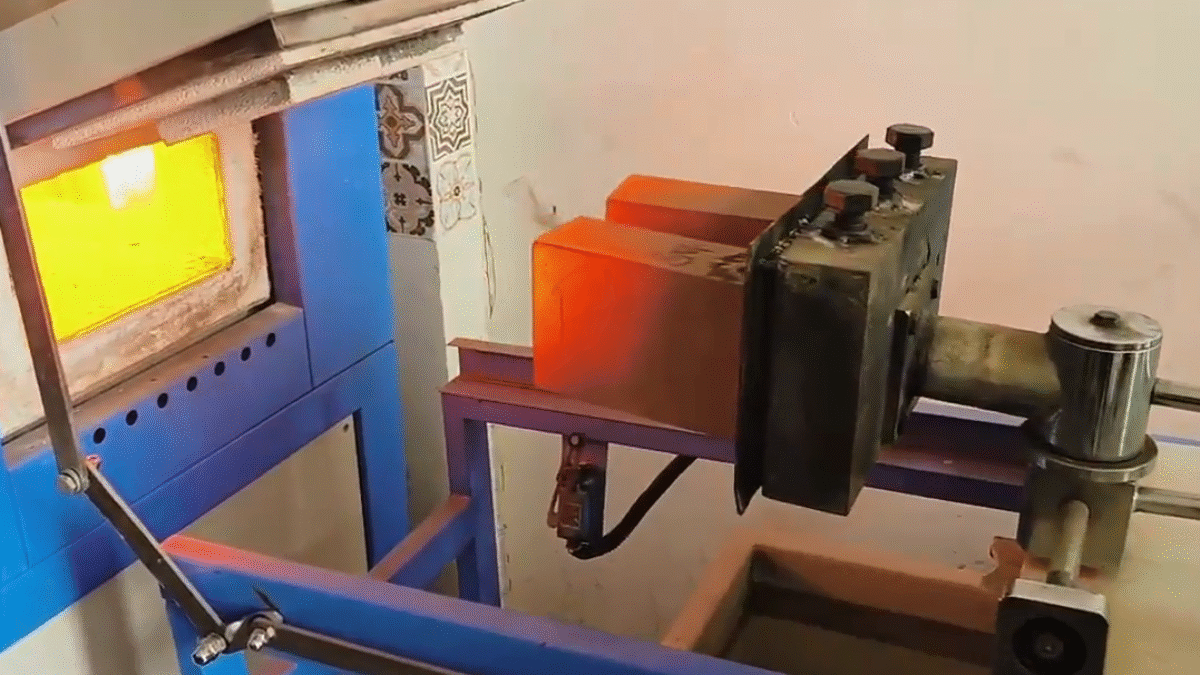

- Environmental simulation: Temperature cycling, humidity, thermal shock, salt spray, corrosion resistance.

- Coating & surface finish testing: For components exposed to wear, grime, road salt, UV.

- Component & assembly level validation: Ensuring parts function not just in isolation but within real sub-systems.

These are precisely the kinds of services you expect when you search for “automotive testing lab services in India – Kiyo R&D Lab”.

Why India is a strategic location for automotive testing services

India has emerged not only as a major manufacturing hub but also a trusted location for testing and validation. Here’s why performing your automotive testing in India can offer significant advantages:

- Cost-efficiency: Setting up sample transport, test rigs, re-work and logistics abroad can multiply cost. A local Indian lab cuts these overheads.

- Turnaround speed: With a lab in India you avoid long shipping delays, customs bottlenecks or time-zone issues. Faster feedback = faster iteration.

- Alignment with Indian OEMs & local supply-chains: If you’re supplying an Indian OEM or Tier-1, local labs understand the expectation and standards. For example, the Global Automotive Research Centre (GARC) in Oragadam, Tamil Nadu is a major centre for automotive testing in India. Wikipedia+1

- Growing sophistication: Testing standards in India are keeping pace with global requirements. Labs are acquiring international-grade accreditation.

- Convenience & scaling: Scaling from prototypes to pilot to series volumes is easier when your testing partner is locally accessible.

When you decide to engage “automotive testing lab services in India – Kiyo R&D Lab”, you’re tapping into these benefits.

How to engage with Kiyo R&D Lab efficiently

Here’s a step-by-step guide to making the most of your testing engagement:

- Define your scope clearly

Share part drawings, intended use environment (temperature, salt spray, mechanical load), standards to meet (ISO, SAE, BIS), sample quantities and timelines. - Provide representative samples

It’s best to test production-equivalent parts (coating, substrate, finish, pre-treatment) so the results translate to real performance. - Condition & pre-test checks

Some tests require pre-conditioning (e.g., 24 h at temperature/humidity) or checking film thickness/adhesion before proceeding. - Execute testing

The lab carries out the agreed-upon tests—durability cycles, mechanical shock, environmental exposures, assembly function, etc. - Report & review

You receive a detailed report: test parameters, results, pass/fail status, reference standards, photographs, observations and recommendations for next steps. - Action & iterate

If any failures occur, you can use the data to refine your design or process and retest. This iterative cycle reduces surprises in customer labs or field failure.

By following these steps, you maximise the value of your automotive testing lab services and avoid costly surprises later.

Typical benefits of choosing Kiyo R&D Lab

Here’s what you gain when you engage with us under the “automotive testing lab services in India – Kiyo R&D Lab” umbrella:

- Risk reduction: Early detection of design or manufacturing flaws before full-scale production or customer validation.

- Quality evidence: A credible test report gives OEMs and Tier-1s confidence in your component.

- Time savings: Faster iteration and fewer delays in your product launch cycle.

- Cost-savings: Avoiding recall, rework and warranty issues by validating up front.

- Continuous improvement: The insights from testing help you refine material selection, finish, assembly or protection systems.

In short, the right lab partner does more than test—you gain data, insight, and a faster validation path.

What kinds of components & systems benefit most?

When you search for “automotive testing lab services in India – Kiyo R&D Lab”, you’ll find our expertise covers a wide spectrum. Some examples:

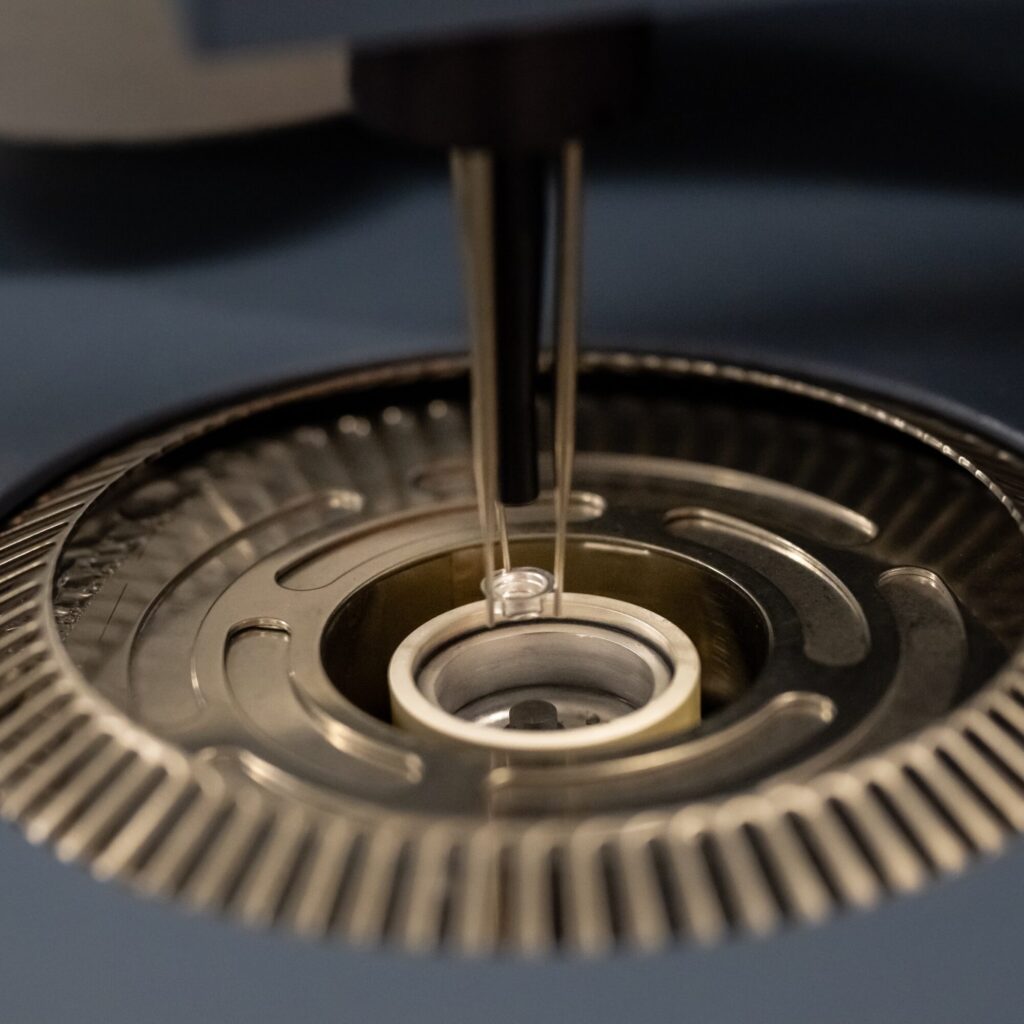

- Powertrain modules: Engine mounts, transmissions, EV motor assemblies, connectors.

- Interior systems: Seats, trim panels, switchgear, electronics modules.

- Exteriors & body-in-white: Panels, brackets, fasteners, coatings.

- Electrical / electronics: Wiring harnesses, high-voltage components, ECU enclosures.

- New-technology components: EV batteries, ADAS sensors, infotainment modules, connectivity units.

- Commercial & off-highway equipment: Tracks, agricultural vehicles, construction vehicles where durability is paramount.

This breadth ensures your component or system can be handled under one umbrella rather than bouncing between multiple labs.

Final thoughts

In today’s competitive automotive landscape, having the right partner for “automotive testing lab services in India – Kiyo R&D Lab” gives you a real advantage. You’re not just paying for a test—you’re investing in confidence, data integrity and a smoother product-launch path.

If you’re preparing for a new product, validating a critical component, or simply want to avoid downstream surprises—let’s talk. At Kiyo R&D Lab we’re ready to help you define your scope, get accurate results and move forward with assurance.

Reach out today and let’s help you deliver parts that stand up to the road.