Flammability Testing Services in India

Flammability Testing Services in chennai

Introduction

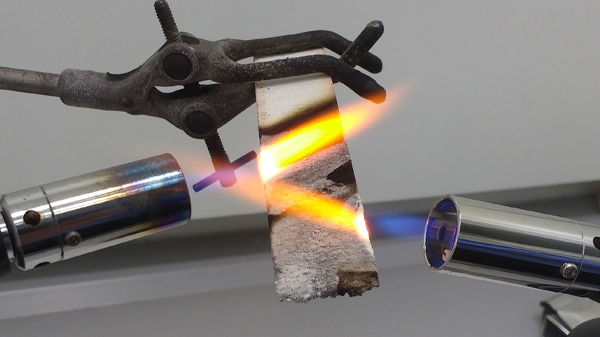

You know how crucial safety is—especially when materials meet heat, flame, or extreme conditions. Whether you’re in electronics, textiles, automotive, building materials, or consumer goods, any component that might face fire or ignition risk must be tested thoroughly.

If you’re looking for Flammability Testing Services in India – Kiyo R&D Lab, you’re likely seeking a lab that offers reliable, accredited, and technical fire‑safety evaluations for materials and finished products. In this blog, I’ll walk you through:

- What flammability testing really means (and why it matters)

- Common tests and standards

- What a top lab like Kiyo R&D Lab should or could offer

- How to pick the right flammability testing partner

- Use cases, challenges, and best practices

By the end, you’ll know what to expect, what to ask, and how to present this offering on your site (or choose it for your project).

Why Flammability Testing Is Critical

Protecting Lives, Property & Reputation

A material that ignites too easily or burns too intensely can pose serious hazards—fire, smoke, structural damage, even loss of life. Brands and manufacturers can’t afford to gamble. Flammability testing is a cornerstone of safety assurance.

Regulatory & Market Access Requirements

Different countries and industries have fire safety standards. For instance:

- Building materials might need to comply with fire codes (like ASTM E84, UL 723)

- Plastics might need to pass UL 94 vertical/horizontal burn tests (for electronics, enclosures) Applied Technical Services+1

- Textile or consumer goods may require standards for reaction to fire or flame spread

- Some industries require full fire resistance, smoke density, or reaction‑to-fire grades

Without passing these, a product might be barred from sale, recalled, or face liability.

Material Qualification & R&D

When you develop a new polymer blend, fire‑retardant additive, coating, or composite, you need to know how it performs under flame. Flammability testing helps you iterate formulations and confirm improvements.

Failure / Incident Investigation

When something fails under fire exposure—say a plastic part ignites or a insulation burns—you need root cause analysis. Testing labs can run controlled flammability tests, examine residues, compare behavior, and help you correct design or material choices.

Because of this, flammability testing is not a luxury—it’s a necessity for responsible product development and market success.

Understanding Flammability Tests & Standards

To appreciate what you should demand from a lab like Kiyo, let’s review common tests, what they measure, and what they mean.

| Test / Method | Measures / Purpose | Typical Standards / Use Cases |

|---|---|---|

| UL 94 (Horizontal / Vertical Burn) | How a plastic or component behaves under flame exposure (self‑extinguishing, dripping, etc.) | Widely used in electronics, enclosures |

| ASTM D635 / ASTM D3801 | Horizontal / vertical burn rate of plastics and polymers Applied Technical Services | Determines burn rate, classification |

| ASTM E84 / UL 723 (Surface Burning Characteristics) | Flame spread index, smoke developed index across surfaces / panels | Roofing, wall panels, building materials |

| Cone Calorimeter / Hood Calorimetry | Heat release rate, time to ignition, combustion behavior | Advanced fire property profiling |

| Ignition, Flame Spread, Combustibility, Flash Point | Susceptibility to ignition, how flame spreads, combustibility metrics | Various ISO/ASTM/UL standards TÜV SÜD+1 |

| Smoke Density / Toxic Gas Emission | How much smoke (or gases) a burning material emits | Critical for enclosed spaces or stringent safety regulation |

| Fire Resistance / Fire Endurance (for assemblies) | How long a structure or assembly withstands fire | Used in building codes, construction product testing |

More generally:

- Flammability tests assess reaction to fire (how a material contributes to flame) rather than just resisting fire.

- Some labs are ISO/IEC 17025 accredited, meaning their results carry recognized quality and traceability.

- The choice of test depends on your product type (plastic part, wall panel, textile) and the regulatory or industry standard you aim to meet.

What “Flammability Testing Services in India – Kiyo R&D Lab” Should Encompass

When you refer to Flammability Testing Services in India – Kiyo R&D Lab, you’re branding a comprehensive fire safety testing offering from Kiyo. To live up to that, here’s what a top‑tier lab should or could provide:

Accreditation & Credibility

- NABL accreditation (or equivalent) for fire / flammability test scopes

- Traceability, quality control, calibration records

- Clear documentation of method, instrument calibration, uncertainty

Broad Test Portfolio

Kiyo should offer all relevant flammability tests, including but not limited to:

- UL 94 (HB, V‑0, V‑1, V‑2) and equivalents

- ASTM D635, D3801, or polymer burn tests

- ASTM E84 / UL 723 for panel / surface burning

- Cone calorimeter / calorimetry methods

- Ignition, flame spread, combustibility, flash point

- Smoke density / gas emission tests

- Fire resistance tests for assemblies (if infrastructure allows)

- Reaction to fire classification

Industry-Specific Modules

They should handle specialized needs for:

- Electronics & consumer goods

- Automobiles (interior plastics, dashboard, trims)

- Construction & building materials

- Textiles, upholstery

- Composites, coatings, flame-retardant materials

R&D & Formulation Support

Beyond pass/fail, they should help:

- Optimize formulations with flame-retardants

- Interpret trends, propose modifications

- Assist in pre-testing (screening tests before full certification)

Failure Analysis & Forensics

- Post‑burn residue analysis

- Microscopy, SEM, chemical analysis

- Comparative testing with control samples

Logistics, Speed & Reporting

- Sample pickup, guidance for shipping

- Reasonable turnaround times

- Clear, actionable reports with graphs, comparisons, remarks

- Confidentiality and IP protection

If Kiyo R&D Lab positions itself under the banner Flammability Testing Services in India – Kiyo R&D Lab, then they should strive to meet or exceed these expectations.

How to Choose a Flammability Testing Lab

Selecting the right lab is crucial. Here are the factors you should evaluate (and questions to ask):

1. Accreditation & Recognition

Ensure they hold credible accreditation (e.g. NABL in India). Accreditation assures their results are accepted by regulators and industries.

2. Test Scope & Equipment

Does the lab have the equipment you need (cone calorimeter, vertical burn rigs, large furnaces)? If they subcontract certain tests, ask who and where.

3. Domain Experience

A lab familiar with your industry (electronics, building, textiles) will better interpret standards and tailor methods.

4. Turnaround Time

Fire safety testing can be time-sensitive. Ask what their typical lead times are and if “rush” options exist.

5. Sample Logistics

Do they assist with packaging, sample transportation, or remote sites? Especially in India, shipments can go awry.

6. Reporting & Clarity

Your report should include raw data, plots, test conditions, deviations, and conclusions. Ask for a sample report.

7. Confidentiality & IP

If you’re testing novel formulations, ensure there are NDAs or confidentiality agreements in place.

8. Technical Support & Consultation

A lab that helps you interpret results, refine materials, or design further tests is extremely valuable.

9. Cost vs Value

It’s tempting to pick the cheapest lab, but low cost with poor quality is risky. Value means accuracy, timely results, and expert support.

In effect, Flammability Testing Services in India – Kiyo R&D Lab should be evaluated not just as a “testing provider,” but as a partner in fire safety assurance.

Real-World Use Cases

Here’s how different sectors use flammability testing—and how Kiyo could serve them:

- Consumer Electronics: Plastic enclosures, switches, insulators must pass UL 94, smoke tests, and surface burning tests.

- Automotive Interiors: Dashboard components, upholstery, trims must meet automotive flame standards (FMVSS, ISO, OEM specs).

- Building Materials: Wall panels, ceiling tiles, insulation, cladding need surface burning assessments (ASTM E84) and fire resistance ratings.

- Textiles & Upholstery: Fabrics, curtains, furniture covers require reaction-to-fire tests to ensure controlled flame spread.

- Composite / Coatings / Additive Development: When creating flame‑retardant materials, iteration needs screening via flammability testing.

- Failure Analysis: After a fire event or lab failure, testing helps determine root cause, comparing failed sample vs control.

In each case, your lab must deliver not just data but guidance relative to standards and market expectations.

Challenges & Best Practices

Common Challenges

- Sample preparation: thickness, surface, edge treatments affect results

- Reproducibility & repeatability of tests

- Instrument calibration and drift

- Shipping damage or contamination

- Matching test methods to local vs global standards

- Interpreting borderline or marginal results

Best Practices

- Provide exact sample geometry, conditioning, history

- Pre-screen small versions before full tests

- Use control or standard reference samples

- Engage in pre‑test dialogues with the lab

- Ask for test method deviations or observations

- Document all handling and environmental conditions

- Maintain communication during test progress

When you partner well with the lab, the risks of surprises are much lower.

Conclusion

Fire safety is not optional—it’s foundational. If you’re looking for Flammability Testing Services in India – Kiyo R&D Lab, you want more than just test reports: you want confidence, clarity, and a partner who understands your material, your market, and your standards.

Kiyo R&D Lab should aim to provide NABL‑accredited, full-spectrum flammability test services—from UL 94 to cone calorimetry, smoke analysis, failure forensics, and consultation. But as a user or client, venture carefully: vet their accreditation, test capabilities, reporting quality, logistics, domain experience, and support.

If you like, I can convert this into HTML format, or generate meta tags, FAQ schema, or social media snippets around “Flammability Testing Services in India – Kiyo R&D Lab.” Do you want me to do that next?

Rubber Lab Testing Services in India

Rubber Lab Testing Services in chennai

Introduction

In today’s competitive product landscape, quality and reliability are no longer optional—they’re essential. Especially when working with rubber and elastomeric materials, slight variations in compound, process, or aging can drastically affect performance, longevity, and safety. Whether you’re manufacturing seals, hoses, gaskets, O‑rings, vibration mounts, or custom molded rubber parts, you need robust testing to prove that your components will stand up to real‑world demands.

That’s where Rubber Lab Testing Services in India – Kiyo R&D Lab comes in. If you’re searching for an Indian partner with deep technical know‑how, certified infrastructure, and a client-focused approach, this blog will guide you through:

- Why rubber testing is so critical

- The major tests and methodologies

- The landscape of rubber testing in India

- What makes Kiyo R&D Lab a compelling choice

- How to get the most value from your testing

By the end, you’ll see how positioning your service as “Rubber Lab Testing Services in India – Kiyo R&D Lab” helps you connect with clients who care about precision, regulatory compliance, and material integrity.

Body

1. Why Rubber Testing Matters

1.1 The Nature of Rubber: Complex & Sensitive

Rubber is a polymeric, viscoelastic material—its performance properties depend not just on composition but on how it’s processed, aged, and stressed over time. A tiny impurity, an inconsistent cure, or slight variation in filler dispersion can lead to failure. Without proper testing, hidden flaws may haunt your final product.

1.2 Real Risks from Poor Rubber Quality

- Leakage or sealing failure — in gaskets, O‑rings, or seals

- Material degradation or cracking — under heat, ozone, UV, or chemical exposure

- Loss of mechanical performance — reduced tensile strength, elongation, tear resistance

- Unexpected aging or hardening — making parts brittle

- Noncompliance with customer or regulatory specs

Given these risks, rigorous testing becomes your shield against warranty claims, recalls, and reputation damage.

1.3 Business & Regulatory Drivers

- Many industries demand compliance with standards (ASTM, ISO, BIS)

- When exporting, test reports from NABL‑accredited labs are often required

- Testing helps in selecting the right rubber grade and design early

- It supports failure analysis and continuous improvement

In short, rubber testing is not just a checkbox—it’s a strategic tool.

2. Essential Rubber Lab Tests & Methods

Below is a rundown of key tests commonly performed in rubber labs. A reliable lab should be able to offer this suite or customize based on your needs.

2.1 Mechanical & Physical Tests

- Tensile Strength & Elongation (e.g. ASTM D412) — measures how far rubber can stretch before breaking

- Tear Resistance (ASTM D624) — ability to resist propagation of a cut or notch

- Hardness Measurement (Shore A, Shore D, IRHD) — how firm the rubber is under indentation

- Compression Set — how well the rubber recovers after compressive stress (ASTM D395)

- Creep & Stress Relaxation — long‑term deformation under load

- Abrasion / Wear Resistance — how rubber resists surface wear

2.2 Aging & Durability Tests

- Heat Aging / Thermal Aging — exposing samples to elevated temperatures and rechecking properties

- Ozone or UV Exposure — evaluating cracking or surface damage in ozone/UV environments

- Cold Temperature Testing / Low‑Temperature Flexibility

- Cyclic Fatigue / Dynamic Fatigue — repeated loading and unloading to simulate real usage

2.3 Chemical & Environmental Tests

- Swelling / Solvent Resistance — how rubber absorbs or resists fluids like oils, fuels, solvents

- Chemical Resistance — exposure to acids, bases, corrosive media

- Weatherability / Accelerated Weathering

- Aging in Humidity or Water

2.4 Analytical / Composition Tests

- Ash / Filler Content / Inorganic Content — via TGA or ignition methods

- FTIR / Infrared Spectroscopy — to identify polymer type or contaminants

- Differential Scanning Calorimetry (DSC) — thermal transitions, glass transition temperature

- Thermogravimetric Analysis (TGA) — decomposition profiles, stability

- Elemental / Spectroscopic Analysis — checking for harmful additives or spread of fillers

2.5 Electrical / Insulation Tests (for specialized rubbers)

If you’re using rubber in electrical insulation or sealing around electronics, labs may also offer dielectric strength, resistivity, breakdown voltage, etc.

3. The Indian Rubber Testing Landscape

Knowing the current environment helps in choosing the right partner.

3.1 Accreditation & Trust

In India, the NABL (National Accreditation Board for Testing & Calibration Laboratories) is the benchmark for lab competence (ISO/IEC 17025) Wikipedia. A lab that is NABL‑accredited commands much greater trust—especially when dealing with regulators, OEMs, or overseas clients.

Kiyo R&D Lab’s website shows that they serve the “Plastics & Rubber” domain as part of their core testing services. Kiyo R&D Center and Laboratory

3.2 Existing Players & Competitors

- FAN Services offers NABL‑accredited rubber testing, from simple grade ID to advanced material analysis. fan-indiatestinglabs.com

- Vichar Technology provides tests like tensile, hardness, compression set, swelling, filler content, aging etc. vichartechnology.com

- AMO Laboratories offers polymer & rubber testing across India, covering many cities. AMO Laboratories Private Limited

- HASETRI (Hari Shankar Singhania Elastomer & Tyre Research Institute) is a high‑profile independent rubber & tyre R&D & test center. hasetri.com

- The Auto Cluster Rubber Polymer Lab (RPL) in Pune is a recognized NABL‑ISO/IEC 17025 lab for polymer and rubber materials. autoclusterpune

3.3 Challenges & Opportunities

- Geographic convenience: clients often prefer labs closer to their production sites to reduce logistics risks

- Equipment sophistication: not all labs have advanced instrumentation like DSC, TGA, fatigue test rigs

- Turnaround time: competition is on speed, quality, and adaptability

- Custom & rare tests: the ability to develop or execute non‑standard or hybrid tests is a differentiator

Given this, a lab that combines core capabilities, accreditation, and customer orientation can stand out.

4. Why Choose Rubber Lab Testing Services in India – Kiyo R&D Lab

Let’s zoom into what Kiyo R&D Lab brings to the table and how it can be your trusted partner.

4.1 Overview & Expertise

- Kiyo R&D Lab presents itself as a materials and product testing laboratory with services in plastic, rubber, metal, coatings, etc. Kiyo R&D Center and Laboratory+1

- They list “Plastic and Rubber Testing Laboratory” as part of their domain, indicating they have domain competence. Kiyo R&D Center and Laboratory+1

- Their public-facing pages mention regional operations (e.g. a page for Rubber Testing Lab in Chennai). Kiyo R&D Center and Laboratory

- Their profile on LinkedIn also highlights “Rubber Testing” among services. LinkedIn

Hence, Kiyo is already positioned to cater to rubber testing demands.

4.2 Key Strengths & Differentiators

- Multidisciplinary capabilities — because they also handle mechanical, thermal, electrical, chemical, and degradation testing, clients can combine multiple test scopes under one roof

- Local presence + national reach — less logistic overhead and faster sample turnaround

- Customization — offering “customer / custom standard” testing suggests flexibility in test protocols Kiyo R&D Center and Laboratory

- Brand & SEO alignment — using the phrase Rubber Lab Testing Services in India – Kiyo R&D Lab helps clients searching specifically for rubber testing in India find you

- Credibility potential — though their site doesn’t explicitly list NABL accreditation for every test, their emphasis on “high quality” and “testing laboratory” suggests they operate in a regulated environment Kiyo R&D Center and Laboratory

4.3 What to Require from Kiyo

When engaging Kiyo, here’s what you should ask:

- Accreditation status — for the specific rubber test(s) you need

- Test equipment details — e.g. type of fatigue or aging chambers, thermal analyzers, test frames

- Test methods / standards used — ASTM, ISO, BIS, or custom

- Sample preparation requirements — conditioning, dimensions, tolerances

- Turnaround times & reporting format — raw data, stress‑strain curves, pass/fail conclusions

- Failure analysis support — root cause investigation if your sample fails

- Follow-up or re‑test policy

By partnering this way, you’re not just buying a test — you’re getting actionable insight.

5. Best Practices for Leveraging Rubber Lab Testing

To extract maximum benefit from rubber testing, apply these practices:

5.1 Start Test Planning Early

Don’t wait until your prototype is fully built. Bring the lab in early during material and compound selection to catch issues before tooling or mass production.

5.2 Provide Relevant Context & Use Conditions

Tell the lab your real-world environment—temperature extremes, chemicals, loading, dynamic stresses—so they can simulate meaningful conditions.

5.3 Use Representative Samples & Fixtures

Test realistic parts (or representative sections). Use fixtures that mimic your actual mountings or boundary conditions, not just strips.

5.4 Monitor & Record Thoroughly

Have the lab capture full test curves, raw data, temperature logs, cycles, and any anomaly events. Don’t settle for summary “pass/fail.”

5.5 Iterative Feedback Loop

When a test fails or shows degradation, use the data to refine compound, design, or process. Re‑test to validate improvements. Over time, build a knowledge base.

5.6 Use Comparative / Benchmark Tests

If possible, test competitor or baseline materials side by side to benchmark performance. Sometimes relative performance is more meaningful than absolute numbers.

Conclusion

Rubber is a demanding material—its performance extends beyond mere shape, hinging on chemistry, compounding, processing, and aging dynamics. That’s why Rubber Lab Testing Services in India – Kiyo R&D Lab isn’t just a marketing phrase—it encapsulates a promise: you’ll get precise, credible, localized testing for your rubber parts.

When you choose Kiyo, you gain an integrated lab partner capable of mechanical, chemical, thermal, degradation, and analytical testing. Always confirm accreditation, protocol depth, turnaround, and flexibility before placing a test. Use the data you get back not as a report card but as a design tool—feeding insights back into your material and design development.