Compression Testing Lab in Chennai

High-Precision Compression Testing Services in Chennai

Introduction

- Compression testing out is an essential method for comparing how substances reply to compressive forces. Industries inclusive of automotive, aerospace, construction, and production rely upon this testing out to make sure that substances can withstand mechanical pressure and meet performance standards. By making use of controlled strain, this check enables determine key mechanical homes like compressive energy, modulus of elasticity, and deformation conduct. It is broadly used for high-quality control, cloth selection, and studies purposes.

What is Compression Testing?

Compression testing out measures a material’s capacity to resist compressive loads. It allows analyse:

- Compressive Strength – The maximum pressure a material can undergo earlier than failure.

- Elastic Modulus – The stiffness of the material and the way it recovers after compression.

- Yield Strength – The strain stage at which everlasting deformation begins.

- Failure Mode – Identifying whether or not the fabric cracks, deforms, or buckles under stress.

These houses are important for making sure that substances used in structural and cargo-bearing applications can face up to required forces.

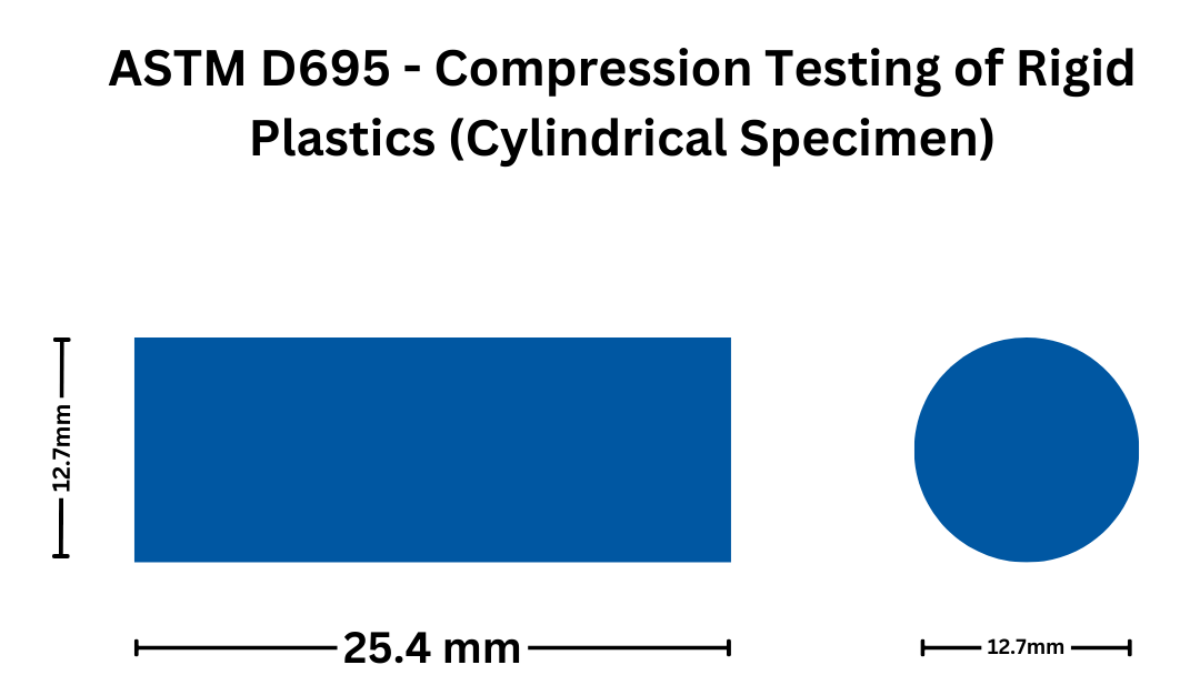

Importance of ASTM D695 in Compression Testing

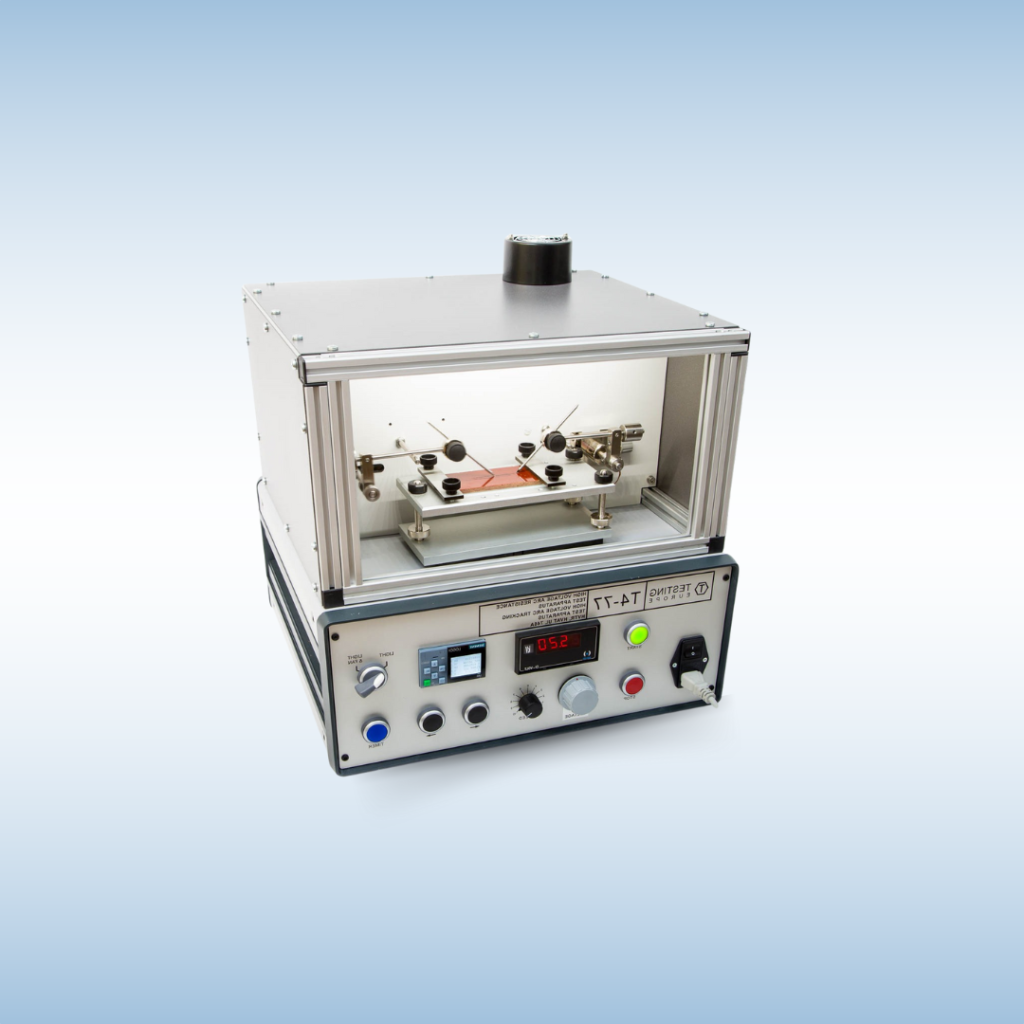

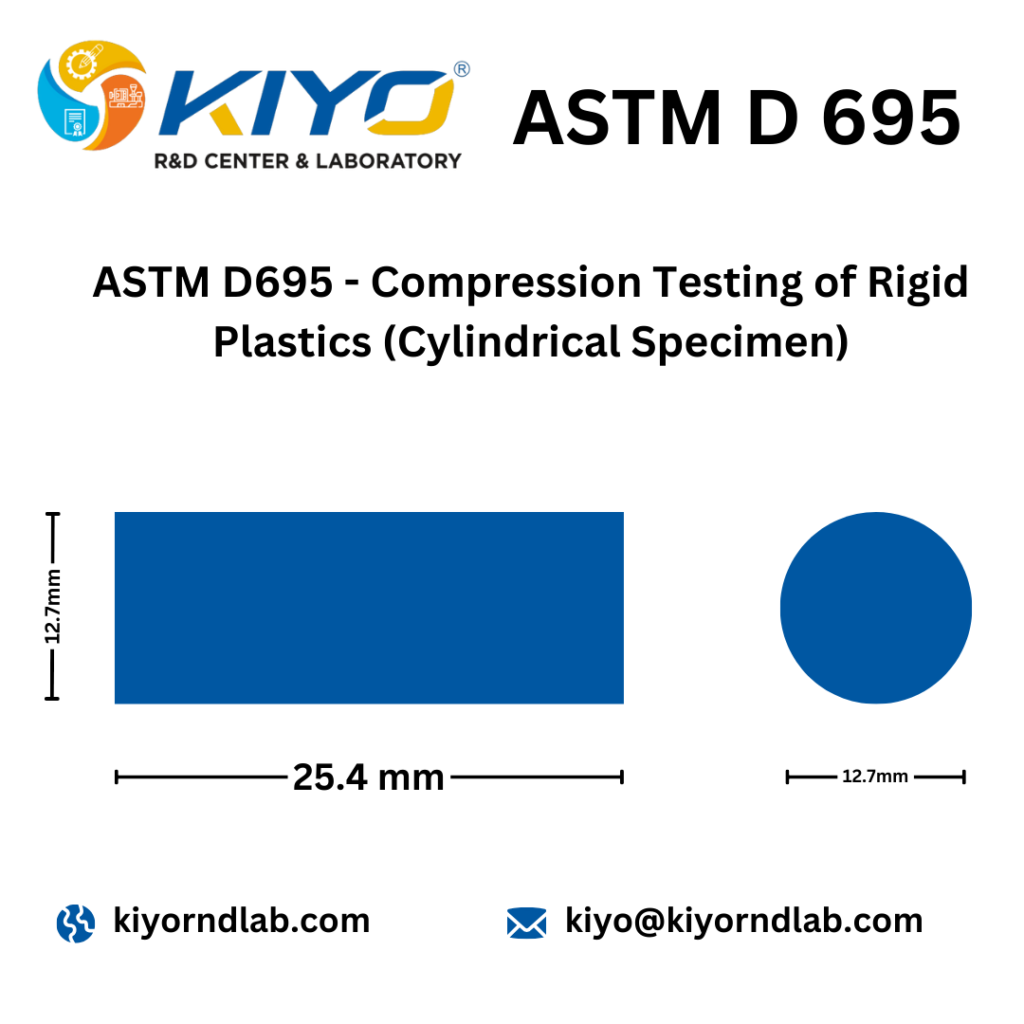

ASTM D695 is the globally identified fashionable for evaluating the compressive residences of inflexible plastics. Following this standard guarantees consistency and accuracy in results.

Key Aspects of ASTM D695 Compliance:

- Specimen Preparation: Precise dimensions and conditioning necessities are observed for uniformity.

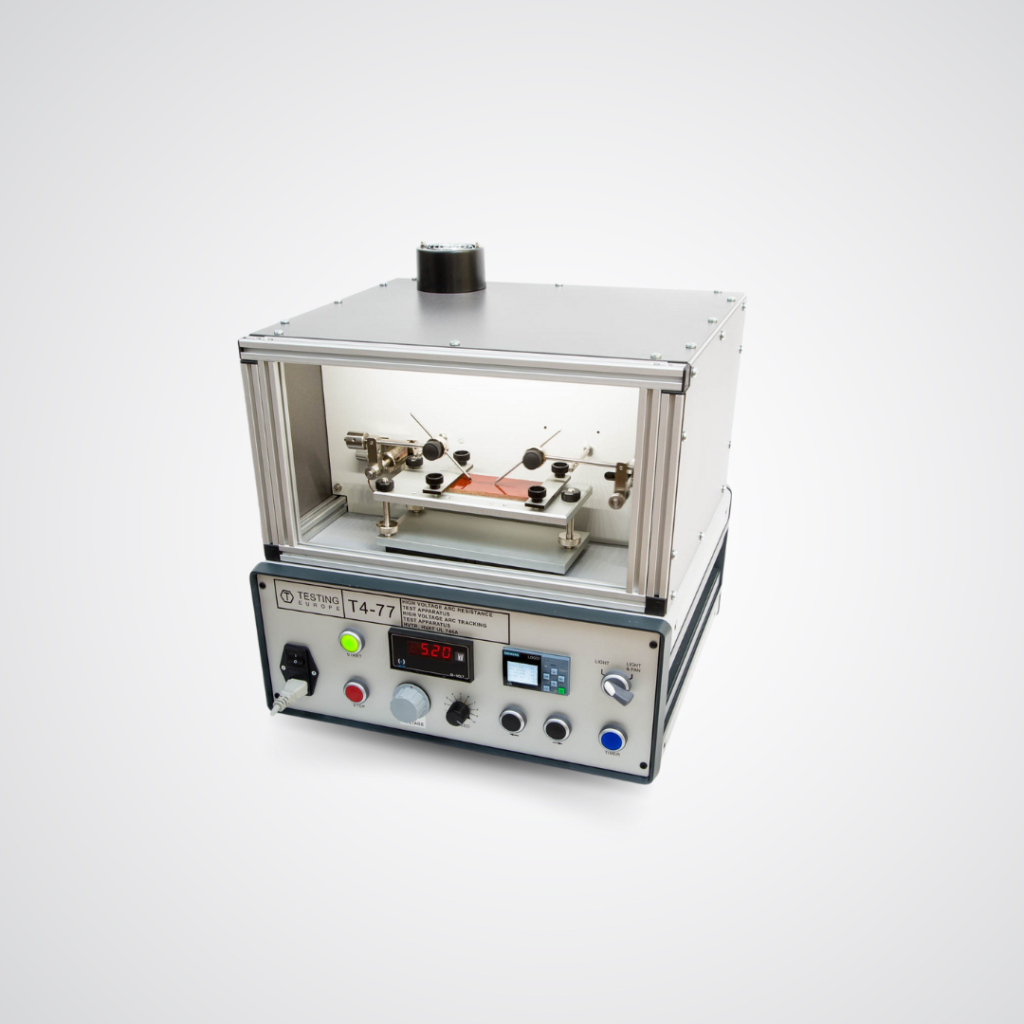

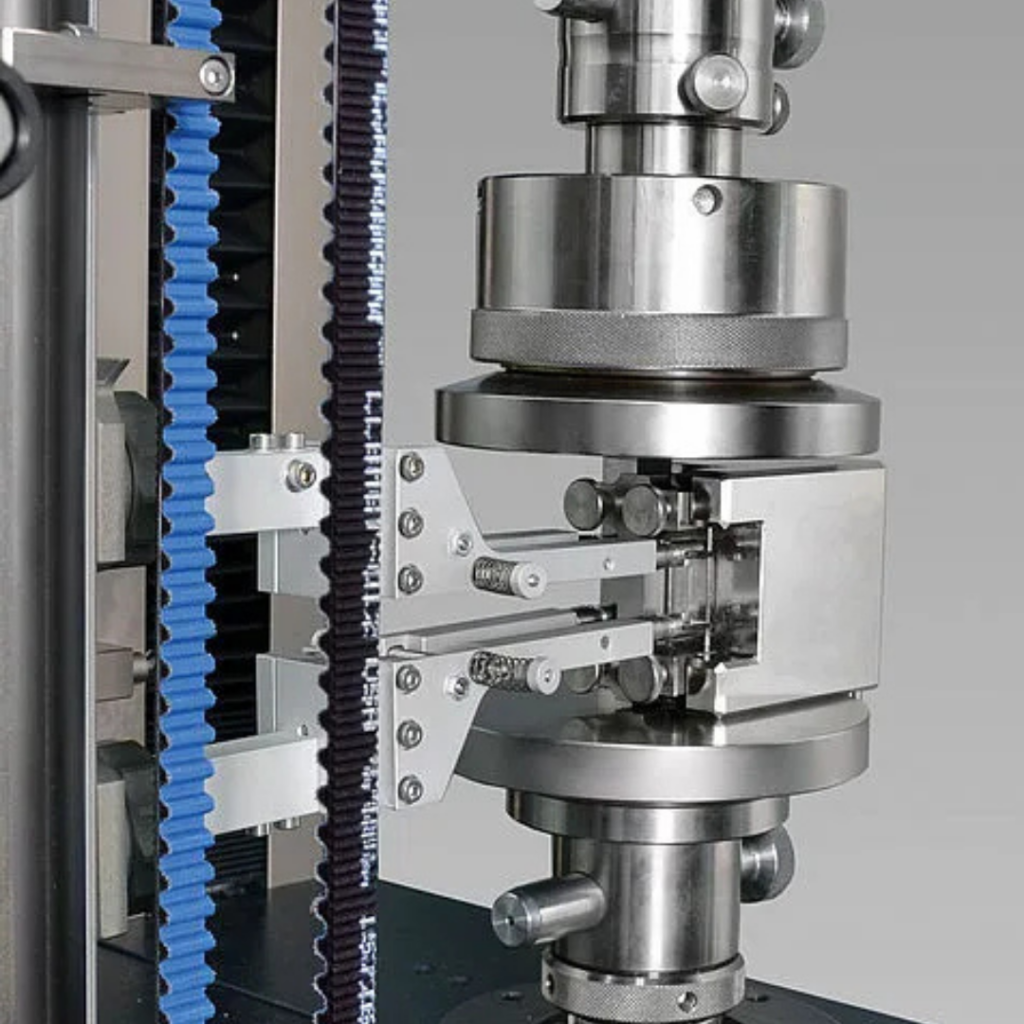

- Testing Procedure: A controlled compressive pressure is applied to the material till deformation or failure happens.

- Data Analysis: Measurements which includes compressive yield strength, strain-stress conduct, and failure points are recorded for assessment.

By adhering to ASTM D695, industries can make certain that take a look at results are accurate and align with worldwide material performance standards.

Advantages of Professional Compression Testing Services

Choosing a specialised laboratory for compression testing gives several blessings:

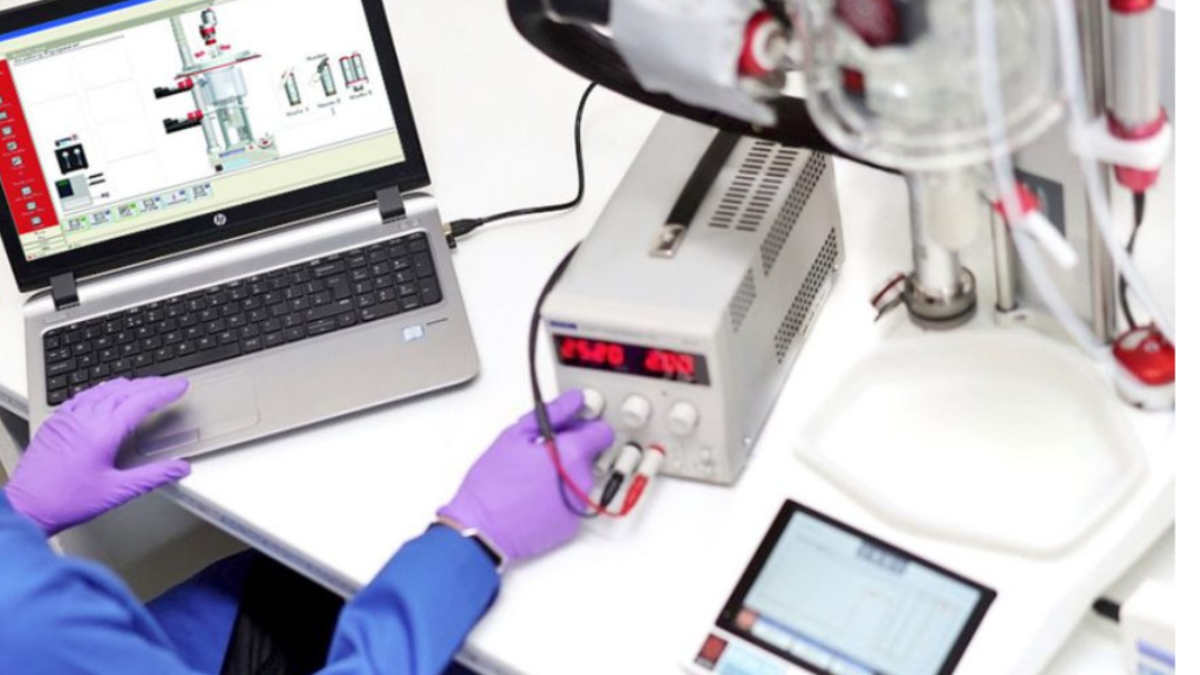

- Advanced Testing Equipment: High-precision machines able to handling plastics, metals, composites, and different materials.

- Expert Analysis: Skilled professionals interpret consequences with precision, ensuring reliable data.

- Detailed Reporting: Comprehensive reports with graphical evaluation, stress-strain curves, and technical insights.

- Fast Turnaround: Efficient testing tactics assist industries meet first-rate manipulate and challenge cut-off dates.

These services guide industries in improving fabric fine, optimizing product layout, and ensuring compliance with enterprise standards.

Applications of Compression Testing

Compression testing is vital across various sectors to validate material sturdiness and overall performance.

Common Industry Applications:

- Automotive: Evaluating plastic and steel components for structural integrity.

- Construction: Assessing building substances like concrete, composites, and polymers for load-bearing programs.

- Aerospace: Testing lightweight, excessive-energy materials used in plane systems.

- Packaging: Ensuring packaging materials withstand external pressures during garage and transport.

- Consumer Goods: Verifying the sturdiness of rigid plastics and other manufactured products.

This testing out enables groups ensure that their materials meet the specified safety and performance criteria for quit-use packages.

Conclusion

- Compression testing out performs a critical function in cloth assessment, helping industries improve product overall performance and reliability. By following global requirements like ASTM D695, manufacturers and researchers can achieve unique and repeatable consequences.