In the world of plastics and engineering materials, impact resistance is one property that can’t be ignored. A material might look strong under slow, steady load — but the real danger comes from sudden impact. A dropped product, a snapped component, a hit during assembly, or an accidental strike on the shop floor — these real-world events can cause brittle failure if the material is not impact-resistant.

To evaluate this critical property, industries rely on the ASTM D256 Izod test, one of the most trusted global standards to measure impact strength of plastics and polymer materials. And when you need reliable, audit-ready, NABL-backed impact testing, choosing the ASTM D256 Izod test lab @ Kiyo R&D LAB gives you the accuracy and credibility your project demands.

This blog breaks down everything — what Izod impact testing is, why it matters, how the test is performed, which industries need it, and why Kiyo R&D Lab is one of the most trusted labs for Izod testing in India.

ASTM D256 Izod Test Lab @ Kiyo R&D LAB – Accurate Impact Strength Testing for Plastics & Engineering Polymers

🔨 What Is the ASTM D256 Izod Impact Test?

The ASTM D256 standard defines how to measure the impact resistance of plastic materials using the Izod method. The test measures how much energy a material can absorb before it breaks when struck by a pendulum hammer.

In simple words:

It tells you how tough or brittle your material is during sudden impact.

The result is expressed in:

- J/m (Joules per meter)

- kJ/m²

- ft-lb/in

This single value helps engineers understand whether the material will crack, break, deform, or survive real-world sudden forces.

The ASTM D256 Izod test lab @ Kiyo R&D LAB uses calibrated equipment, controlled environment, and trained technicians to deliver highly accurate and repeatable Izod values.

🧠 Why Impact Testing Is So Important

Tensile strength and hardness alone do not tell the full story of material performance. A product may:

- withstand steady load

- feel strong in hand

- pass visual QC inspections

BUT still fail instantly when dropped or hit.

Examples:

- A plastic electrical switch cracking on impact

- A molded automotive clip breaking during assembly

- A home appliance component snapping at low temperature

- A packaging material tearing when struck

This is why buyers, suppliers, and manufacturers depend on the ASTM D256 Izod test lab @ Kiyo R&D LAB — to quantify toughness accurately before material approval.

🧪 How the Izod Impact Test Is Performed at Kiyo R&D Lab

The process is scientific, precise, and executed exactly as per ASTM D256:

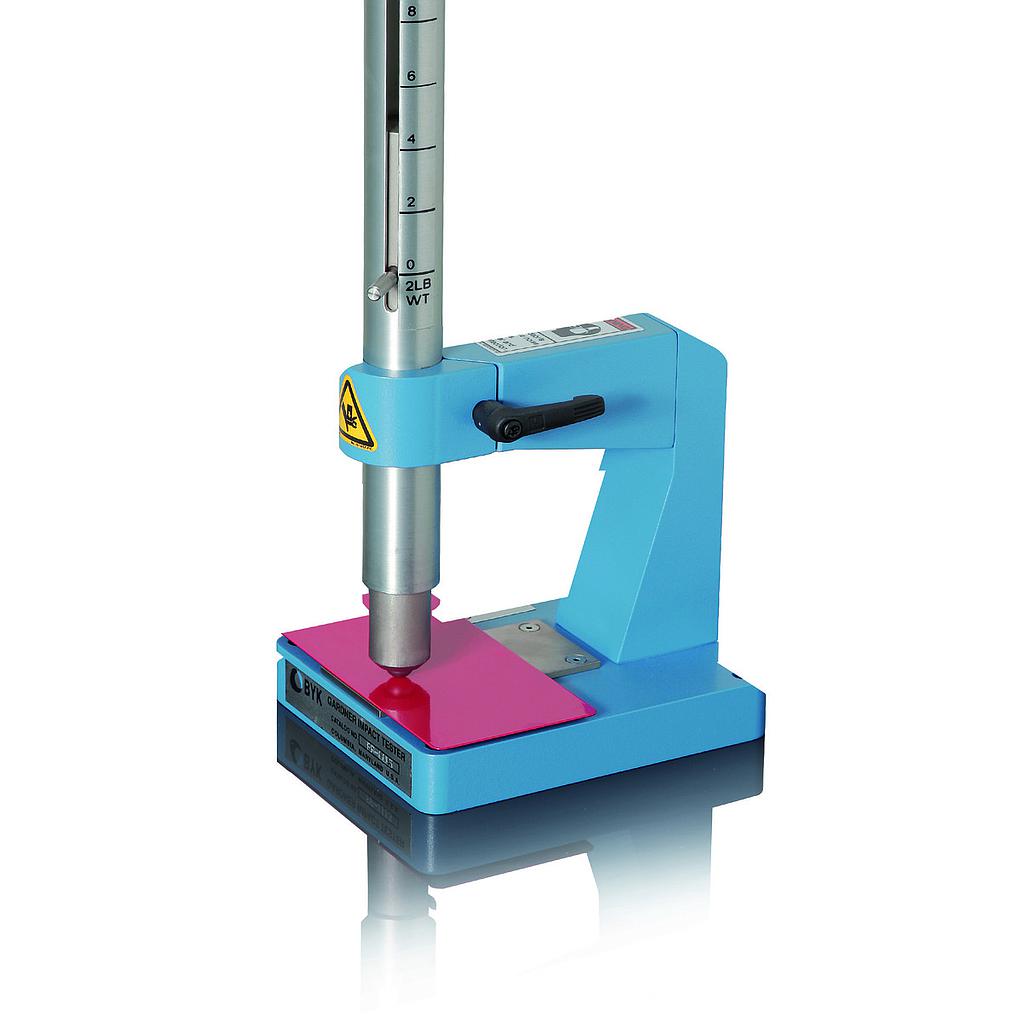

1. Sample Preparation

- Standard size: 64 × 12.7 × 3.2 mm (varies based on material and standard method)

- Samples may be notched or unnotched

The notch acts like a stress concentrator, helping evaluate the weakest point of the material.

2. Conditioning

Samples are kept at controlled temperature and humidity before testing — essential for plastics, as behavior changes with moisture and temperature.

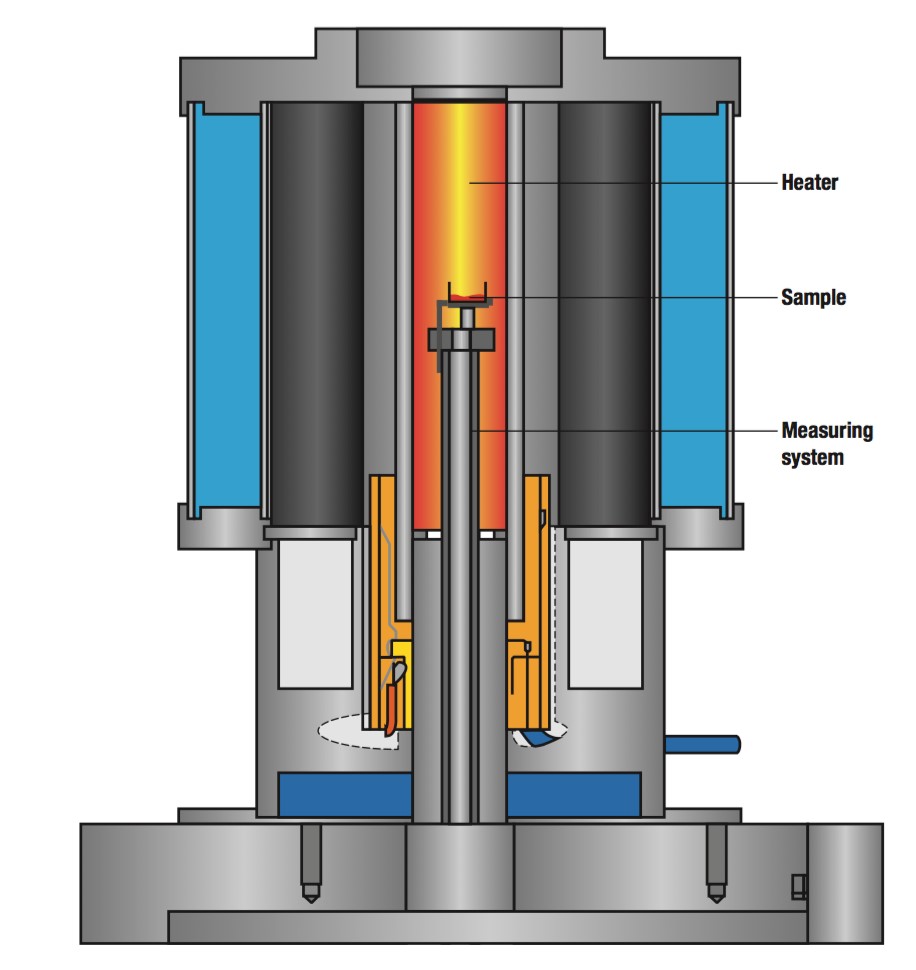

3. Pendulum Impact

A heavy pendulum swings down and strikes the sample with defined energy.

4. Break Type & Energy Absorption

The machine measures:

- How much energy is absorbed before break

- Type of break (complete, partial, hinge, non-break)

- Impact strength value

5. Reporting

Your test report includes:

- Test method

- Notch type

- Pendulum energy

- Impact strength

- Break mode

- Observations

This is why industries choose ASTM D256 Izod test lab @ Kiyo R&D LAB for trusted and audit-ready results.

🔍 What Materials Can Be Tested?

The Izod test is typically used for:

✔ Thermoplastics

HDPE, LDPE, PP, PVC, ABS, PC, Nylon, PET, PBT, PMMA, etc.

✔ Engineering Plastics

Polycarbonate, glass-filled nylon, acetal, reinforced polymers.

✔ Composites

Fiber-reinforced materials, molded composite sheets, FRP components.

✔ Molded Components

Injection-molded parts, clips, housings, thin sections.

✔ Masterbatches & Compounds

To compare toughness of different formulations.

If your material can break under impact, it can be evaluated at the ASTM D256 Izod test lab @ Kiyo R&D LAB.

🏭 Which Industries Need Izod Impact Testing?

Impact testing is widely demanded by:

Automotive Industry

For bumpers, trims, under-the-hood parts, clips, fasteners, dashboards, and connectors.

Electrical & Electronics

Switch housings, plugs, sockets, enclosures, consumer appliances.

Packaging

Rigid containers, bottles, caps, lids, protective casings.

Consumer Goods

Toys, kitchen products, accessories, hardware items.

Construction & Infrastructure

Pipes, fittings, profiles, reinforcement components.

Engineering Colleges

For final-year projects and academic research using polymers and plastics.

These industries frequently rely on the ASTM D256 Izod test lab @ Kiyo R&D LAB to validate material toughness and ensure product reliability.

🏅 Why Choose Kiyo R&D Lab for Izod Impact Testing?

Here’s what makes the difference:

✔ NABL Accredited Facility

Accuracy that is trusted by auditors, clients, cross-functional teams, and international buyers.

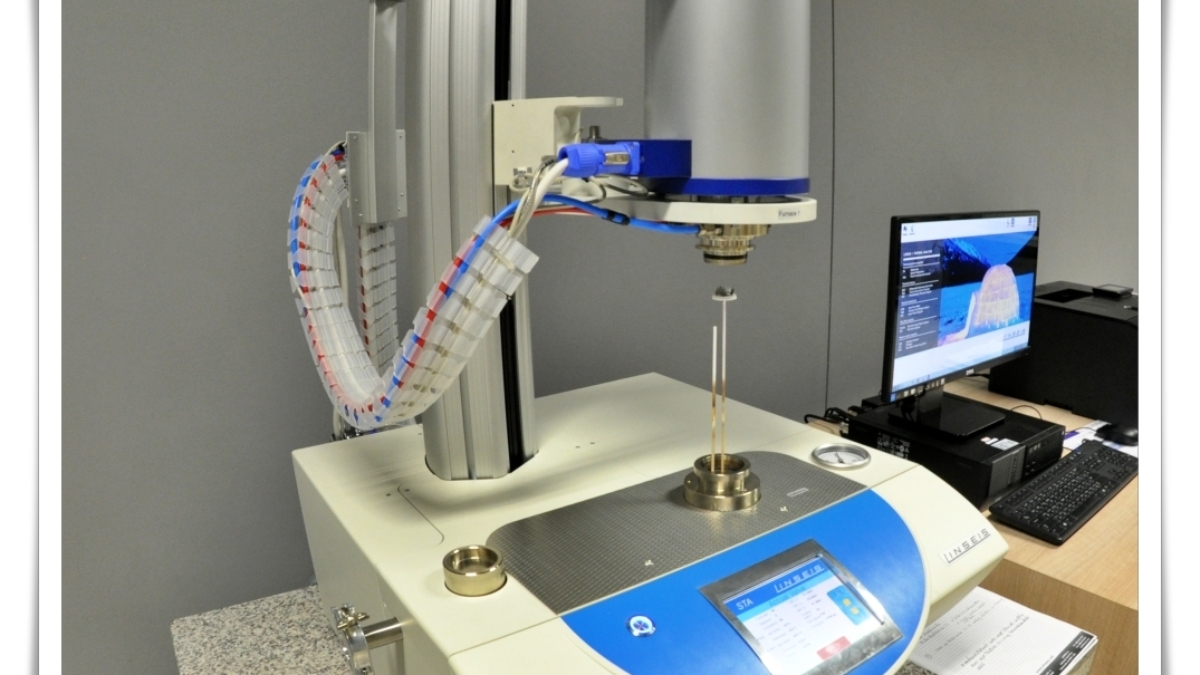

✔ High-Precision Impact Testing Machine

Calibrated pendulum system, adjustable masses, and controlled environment.

✔ Strict ASTM D256 Compliance

Ensures your results are consistent with global specifications.

✔ Fast Turnaround Time (1–2 days)

Ideal for urgent shipment approvals or project submissions.

✔ Experts in Polymer Material Science

Guidance on interpreting results, comparing materials, and understanding break patterns.

✔ Supports R&D, QC, and Failure Analysis

Perfect for comparing new formulations, assessing supplier quality, or diagnosing brittle failures.

When industries look for reliable impact testing, they often choose ASTM D256 Izod test lab @ Kiyo R&D LAB because the data is trustworthy, clean, and professionally interpreted.

📊 What Your Izod Test Report Includes

A complete test report typically contains:

- ASTM D256 method reference

- Sample dimensions

- Conditioning details

- Notch type and depth

- Pendulum energy

- Impact strength results

- Break mode observations

- Comparison data (if multiple samples)

- Analyst and technical reviewer signatures

This makes the report fully audit-ready, perfect for supplier qualification and buyer documentation.

🧠 How Izod Data Helps Your Product

Toughness is one of the most misunderstood but crucial properties.

Accurate Izod impact testing helps you:

🔹 Compare two different polymer grades

🔹 Validate imported or supplier materials

🔹 Approve materials for production

🔹 Ensure safety in critical components

🔹 Optimize your polymer formulation

🔹 Avoid brittle failure during shipment or assembly

When you choose a ASTM D256 Izod test lab @ Kiyo R&D LAB, you get dependable data that directly improves product quality.

⭐ Final Thoughts

Impact strength defines how a product performs in real life — not just in controlled lab conditions. If your component snaps, cracks, or shatters upon sudden force, the entire product fails. That’s why industries rely on a professional ASTM D256 Izod test lab @ Kiyo R&D LAB to receive accurate, repeatable, NABL-aligned impact testing results.

With high-precision equipment, expert technicians, fast reporting, and deep experience in polymer and material science, Kiyo R&D Lab ensures that your product is backed by strong, dependable data — helping you build safer, tougher, and more reliable components.