Plastic components rarely fail slowly. They fail suddenly — during handling, installation, transport, or real-world use. When that happens, the first question engineers ask is simple but critical: Did we evaluate the impact resistance correctly?

That’s exactly where ASTM D256 Izod Impact Testing services – Kiyo R&D LAB come into play.

At Kiyo R&D LAB, Izod impact testing is not treated as a routine checkbox test. It is a performance-critical evaluation carried out under NABL-accredited conditions, strictly aligned with ASTM D256 requirements, to generate results that are reliable, repeatable, and defensible.

Why ASTM D256 Izod Impact Testing Matters

Plastics may show excellent tensile or flexural strength and still fail catastrophically when subjected to sudden impact. Impact loading is fundamentally different from slow, controlled loading.

ASTM D256 Izod impact testing helps determine:

- Resistance to sudden shock

- Tendency toward brittle or ductile failure

- Sensitivity to notches and stress concentrators

- Toughness of rigid and semi-rigid plastics

Without this data, manufacturers are effectively guessing how a product will behave when dropped, struck, or mishandled.

That’s why ASTM D256 Izod Impact Testing services – Kiyo R&D LAB are essential for real-world validation.

What Is ASTM D256 Izod Impact Testing?

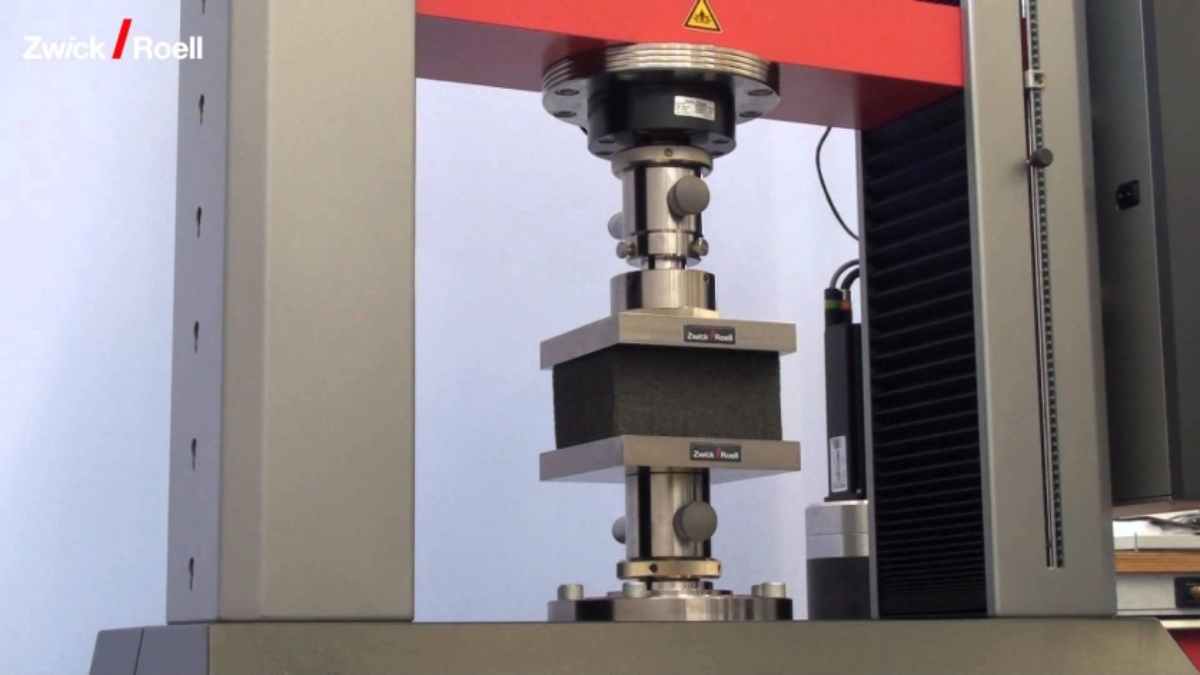

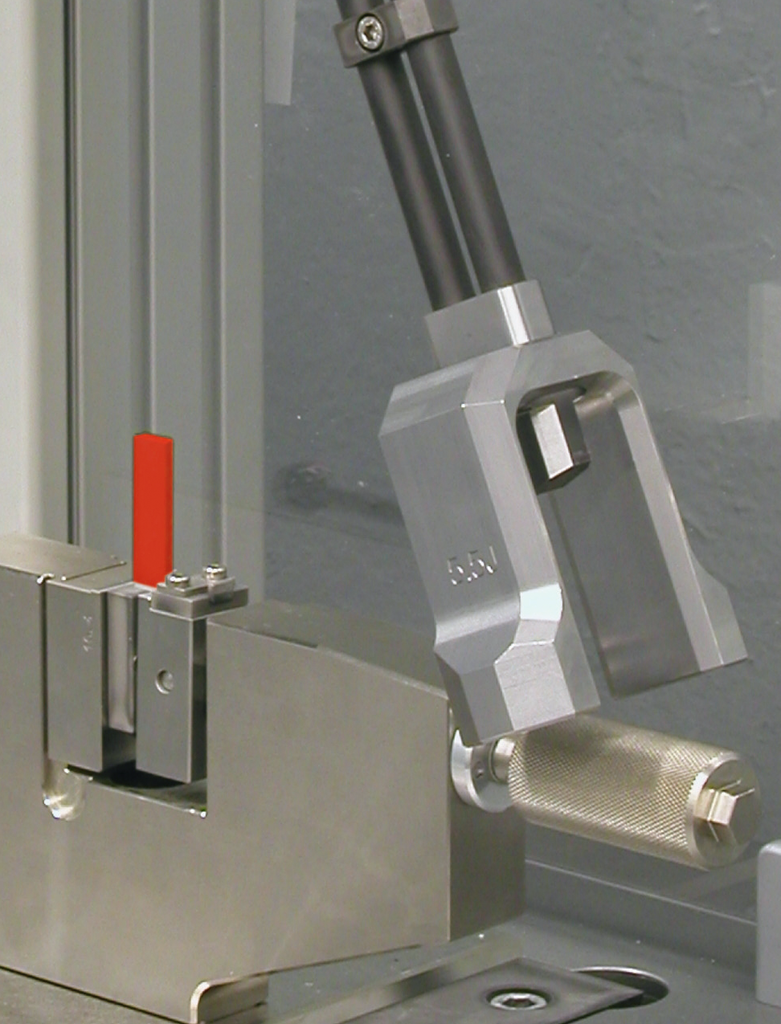

ASTM D256 is a standardized test method used to measure the impact resistance of plastics using the Izod pendulum impact configuration.

In simple terms:

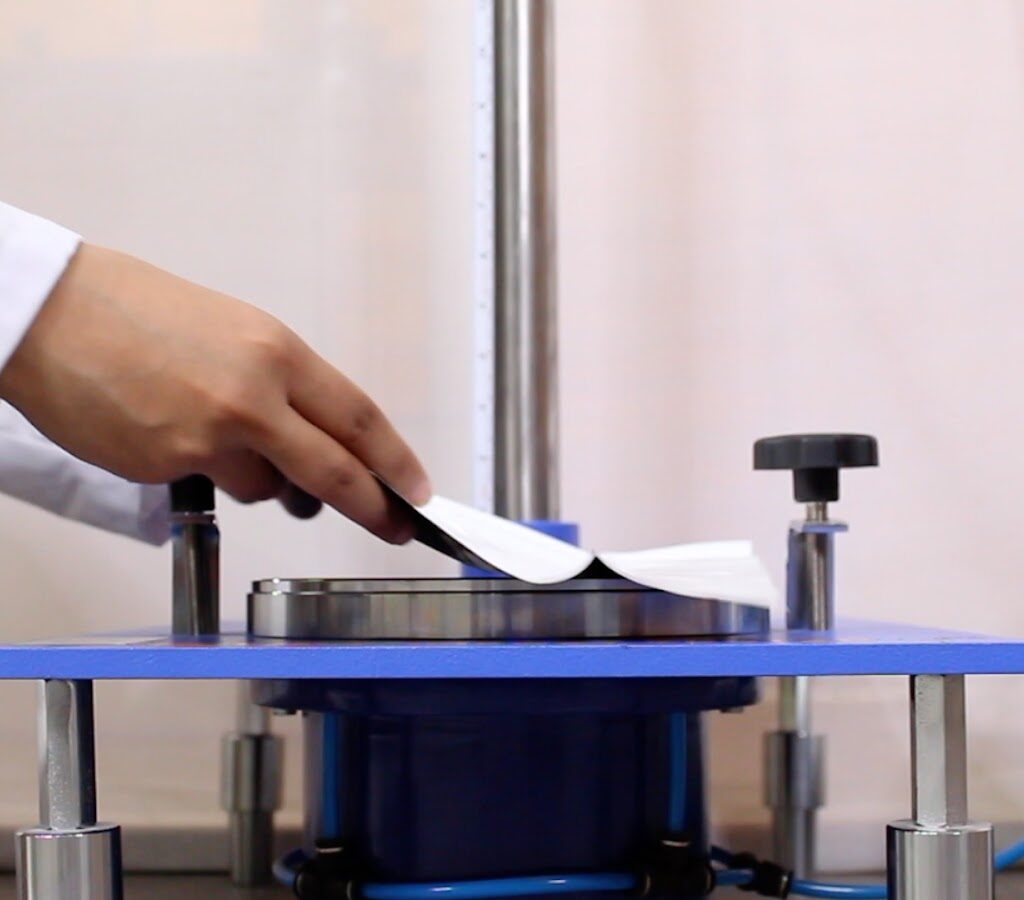

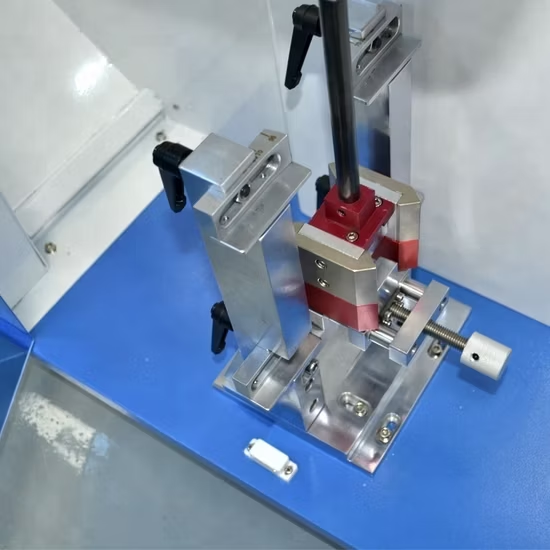

- A notched or unnotched plastic specimen is clamped vertically

- A pendulum strikes the specimen at a defined energy

- The energy absorbed during fracture is measured

The result indicates how much energy the material can absorb before breaking.

At Kiyo R&D LAB, Izod impact testing is conducted strictly as per ASTM D256 to ensure comparability, acceptance, and technical credibility.

Notched vs Unnotched Izod Testing – Why It Matters

One of the most misunderstood aspects of ASTM D256 is the difference between notched and unnotched specimens.

- Notched Izod testing evaluates sensitivity to stress concentration and crack initiation

- Unnotched Izod testing reflects overall material toughness

Many plastic failures initiate at sharp corners, holes, or molded features — which is why notched Izod data is often more representative of real-world behavior.

Choosing the correct configuration is critical. At Kiyo R&D LAB, we guide clients on test selection based on application, not convenience.

Plastics Commonly Evaluated Using ASTM D256

ASTM D256 Izod impact testing is widely used for materials such as:

- ABS

- Polycarbonate (PC)

- Polypropylene (PP)

- Polyethylene (PE)

- PVC, CPVC

- Nylon (PA)

- Acrylics and engineering plastics

Each material responds differently to impact, temperature, and notch geometry — making standardized testing essential.

ASTM D256 Izod Impact Testing at Kiyo R&D LAB

At Kiyo R&D LAB, Izod impact testing is performed under NABL-accredited laboratory conditions, ensuring accuracy and traceability.

Our testing process includes:

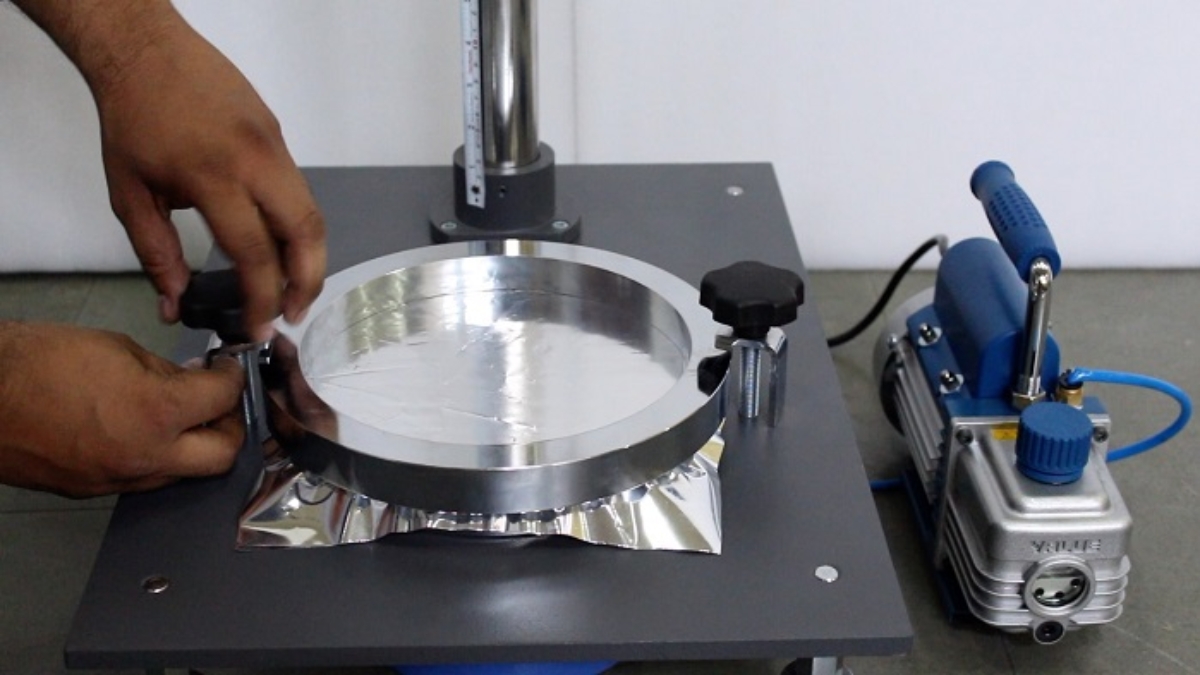

- Proper specimen conditioning

- Accurate notch preparation (where applicable)

- Calibrated impact testing equipment

- Controlled test environment

- Standard-compliant execution

- Clear, structured reporting

Every step is aligned with ASTM D256 requirements, eliminating ambiguity in results.

Why NABL Accreditation Matters for Izod Impact Testing

Impact test results are often used for:

- Customer approvals

- Material qualification

- Audit submissions

- Product benchmarking

- Academic and R&D validation

Non-accredited results may be questioned or rejected.

ASTM D256 Izod Impact Testing services – Kiyo R&D LAB are NABL-accredited, which means:

- Equipment calibration is traceable

- Personnel are trained and authorized

- Test methods are validated

- Reports are audit-ready and accepted

This is especially critical for manufacturers supplying regulated or export markets.

Factors That Influence Izod Impact Results

Izod impact resistance is not a fixed number. It is influenced by:

- Material formulation

- Additives and fillers

- Processing conditions

- Notch quality

- Test temperature

For example, a plastic that performs well at room temperature may fail brittle at low temperatures. That’s why interpreting Izod data without context can be misleading.

At Kiyo R&D LAB, we help clients understand what the numbers actually mean for their application.

Industries That Rely on ASTM D256 Izod Testing

ASTM D256 Izod Impact Testing services – Kiyo R&D LAB are widely used by:

- Plastic product manufacturers

- Automotive and electrical component suppliers

- Packaging manufacturers

- Pipe and profile producers

- Consumer goods brands

- R&D centers and academic institutions

Any plastic component that may be dropped, struck, or mishandled should undergo Izod impact testing.

Common Issues Identified Through Izod Impact Testing

Clients often approach us after facing:

- Cracking during transport

- Breakage during installation

- Brittle failure in cold conditions

- Customer complaints despite passing other tests

- Rejection during quality audits

Izod impact testing helps identify whether the issue is related to:

- Material selection

- Notch sensitivity

- Processing defects

- Inadequate toughness

This transforms trial-and-error into engineering control.

Why Choose Kiyo R&D LAB for ASTM D256 Izod Testing

Let’s be honest — many labs can run an impact test. Very few deliver results you can confidently defend.

ASTM D256 Izod Impact Testing services – Kiyo R&D LAB stand out because we offer:

- NABL-accredited testing environment

- Strict ASTM D256 compliance

- Experienced polymer testing professionals

- Clear, unambiguous reports

- Fast turnaround with priority options

- Support for industry, startups, and students

We focus on decision-ready data, not just numbers on a page.

When Should ASTM D256 Izod Impact Testing Be Performed?

Engage ASTM D256 Izod Impact Testing services – Kiyo R&D LAB when:

- Developing a new plastic product

- Changing raw materials or suppliers

- Comparing material grades

- Investigating impact-related failures

- Preparing for audits or customer qualification

Testing early reduces risk, cost, and reputational damage.

Conclusion

Impact failure is one of the most common and costly issues in plastic products — and it rarely gives a warning.

ASTM D256 Izod Impact Testing services – Kiyo R&D LAB provide manufacturers, designers, and researchers with accurate, NABL-accredited, and practically meaningful impact resistance data.

If your plastic product must survive real-world handling, don’t rely on assumptions or datasheets.

Test it as per ASTM D256. Validate it properly.

That’s the standard at Kiyo R&D LAB.