Xenon Arc Testing

The Power of Xenon Arc Testing: Building Material Resilience for the Future

Introduction

- In these days’s aggressive marketplace, making sure that products can endure actual-global environmental stresses is essential for consumer delight and lengthy-time period emblem fulfillment. One essential test approach used to assess material sturdiness in opposition to outdoor elements is Xenon Arc Testing. Simulating sunlight, moisture, and temperature, this take a look at evaluates how products will carry out over years of exposure, all within a managed lab placing. From automotive components to textiles and coatings, Xenon Arc Testing has come to be a cornerstone for industries centered on sturdiness, look, and overall performance.

What Is Xenon Arc Testing?

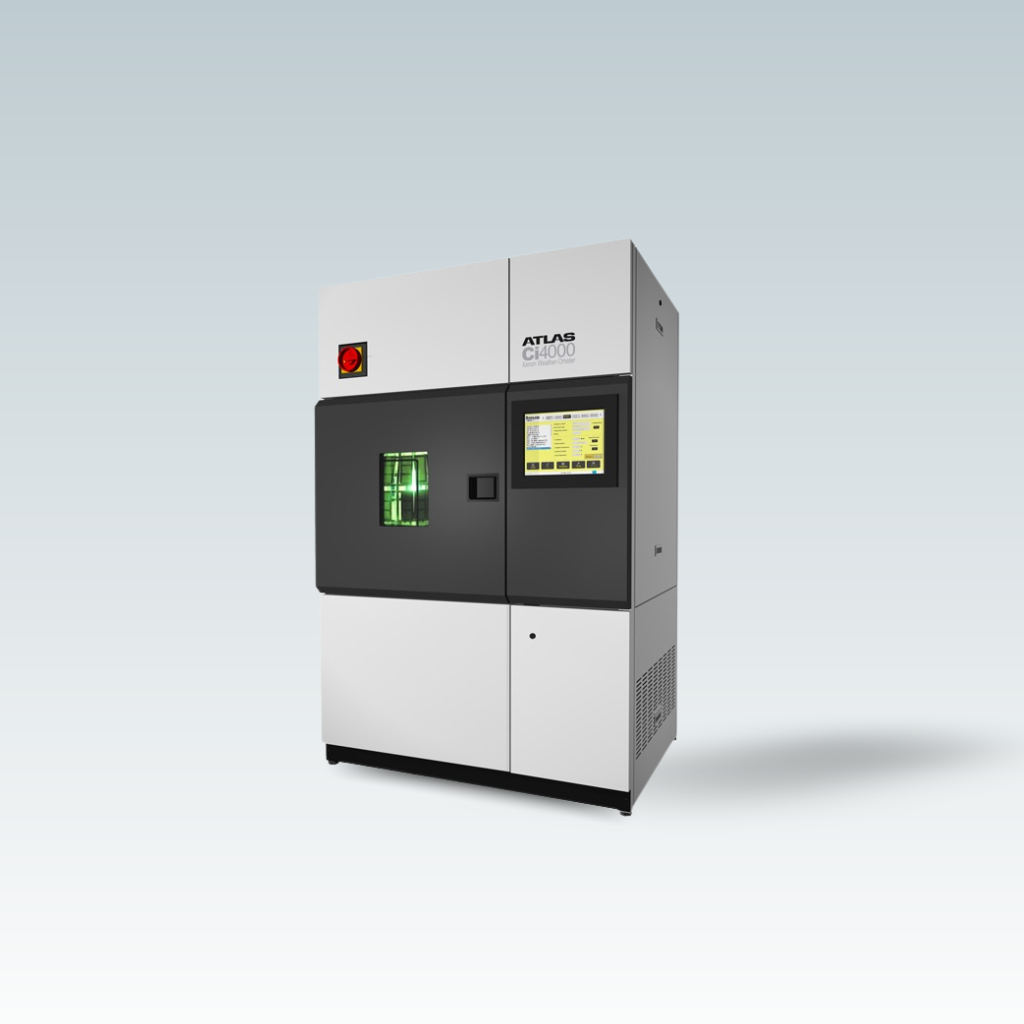

Xenon Arc Testing is a laboratory technique that replicates the overall spectrum of sunlight, consisting of harmful UV rays, via using powerful xenon lamps. It permits for the fast getting older of materials by means of compressing years of exposure to daylight, moisture, and temperature versions into simply days or perhaps weeks. By exposing substances to those intense conditions, manufacturers can pick out ability weaknesses and increase improvements nicely before a product reaches the market.

In addition to light exposure, the xenon arc chamber may be programmed to simulate rain, excessive humidity, and temperature fluctuations. This simulation provides a comprehensive view of how a product would possibly reply to various weather conditions, making it best for packages where durability towards daylight and different environmental elements is critical.

Why Xenon Arc Testing Is Essential

For many industries, the capacity to withstand environmental demanding situations without delay influences product achievement. Here’s how Xenon Arc Testing helps product integrity:

- Accelerated Weathering Simulation: The checking out manner condenses years of natural weathering right into a quick length, allowing manufacturers to advantage insights with out expecting lengthy-term out of doors publicity results.

- Early Problem Detection: By figuring out ability vulnerabilities early on, organizations can make changes earlier than products are released, saving each time and costs in future product recalls or redesigns.

- Enhanced Product Longevity: Xenon Arc Testing enables producers to create materials that keep their sturdiness and appearance longer, meeting patron expectancies for exceptional and durability.

- Compliance with Standards: Many industries require compliance with strict sturdiness and appearance standards. Xenon Arc Testing lets in manufacturers to confirm that their merchandise meet those enterprise requirements earlier than launch.

Key Testing Variables in Xenon Arc Testing

This trying out process can range widely depending at the product and enterprise requirements. Here are the number one variables in Xenon Arc Testing:

- Light Intensity: Xenon lamps emit mild that closely resembles natural sunlight. The depth of this light may be adjusted relying at the sturdiness and exposure requirements of the take a look at material.

- Temperature Control: Different materials react in a different way beneath severe temperatures. The chamber settings can be adjusted to simulate the versions that substances would possibly enjoy in actual-world applications.

- Moisture Simulation: Xenon Arc Testing chambers can mirror rain and humidity, taking into account the evaluation of ways substances keep up towards moisture, water absorption, or degradation over time.

Industries That Rely on Xenon Arc Testing

- Automotive: Automotive manufacturers use Xenon Arc Testing to test components like dashboard materials, exterior trims, and other parts exposed to daylight, making sure they are able to withstand years of publicity without fading or degrading.

- Textiles and Apparel: Textiles, specially those meant for out of doors use, along with upholstery and protecting garb, want to maintain their coloration and structural integrity notwithstanding exposure to sunlight. Xenon Arc Testing guarantees those fabrics meet high sturdiness requirements.

- Building and Construction: Building substances like roofing, coatings, and siding must endure more than a few weather conditions at the same time as preserving their aesthetic and functional properties. This checking out is critical in helping construction substances resist daylight and moisture exposure for prolonged periods.

- Consumer Goods: Many purchaser merchandise, such as outdoor furnishings, electronics, and plastic items, face solar and climate exposure. Xenon Arc Testing guarantees these products can preserve their fine and aesthetic enchantment throughout their lifecycle.

The Xenon Arc Testing Process: A Closer Look

- Preparing the Samples: Each pattern is cautiously organized and installed in the xenon arc chamber, ensuring that conditions healthy specific industry requirements.

- Exposure Cycles: The samples go through cycles of mild and moisture exposure. By adjusting the chamber’s settings, technicians can simulate diverse conditions, from prolonged daylight to intermittent rain and humidity.

- Assessment and Data Collection: Following trying out, samples are analyzed to determine adjustments in color, texture, physical integrity, and different traits. This assessment permits for an in depth understanding of how materials will react over the years in real-world conditions.

Advantages of Choosing Kiyo R&D Center & Laboratory for Xenon Arc Testing

Kiyo R&D Center & Laboratory is dedicated to offering correct and thorough Xenon Arc Testing that meets the needs of diverse industries. By using modern day gadget and techniques, the laboratory offers customers treasured insights into cloth resilience and toughness, supporting them convey better-great merchandise to marketplace with self belief.

The Future of Material Testing with Xenon Arc

- As patron expectations grow, producers ought to ensure that their products perform relatively under a wide variety of environmental conditions. Xenon Arc Testing is not best a step towards handing over strong merchandise however additionally a key detail in enhancing brand popularity and product value. Through this complete checking out technique, industries can live beforehand, continuously improving their substances for long-term achievement. With Xenon Arc Testing, companies can deliver merchandise which are both resilient and reliable, assembly and exceeding the ever-growing requirements of durability in today’s markets.