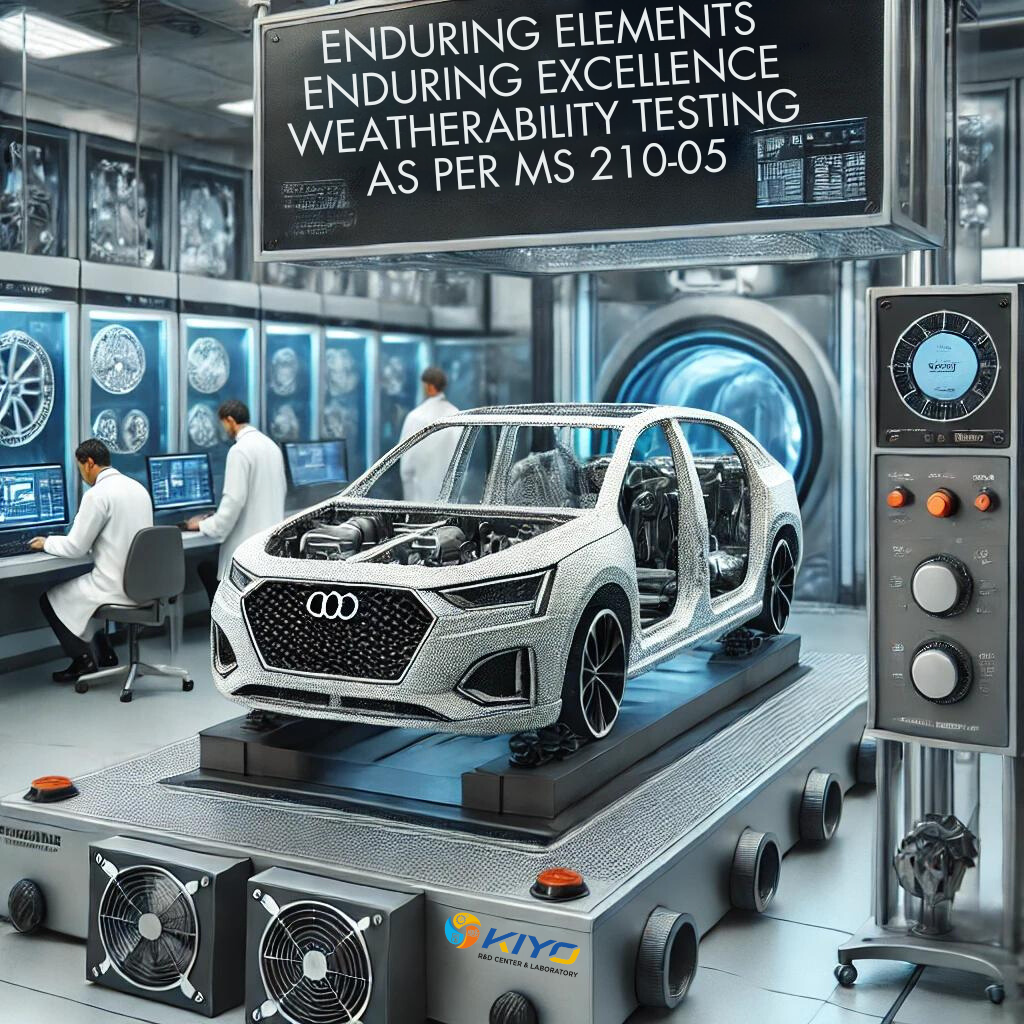

Weatherability Test as Per MS 210-05

Weatherability Testing for Automotive Materials: Adhering to MS 210-05 Hyundai Standards

Introduction

- In the automotive industry, ensuring the durability and aesthetic longevity of materials is essential. Weatherability testing according to MS 210-05 is a critical method for evaluating how well automotive components withstand environmental conditions. This blog delves into the importance, procedure, and benefits of this testing for automotive materials.

Understanding Weatherability Testing

Weatherability testing examines a material’s ability to endure exposure to environmental factors such as UV radiation, temperature changes, and moisture. For automotive materials, this testing ensures that components can withstand harsh conditions without compromising performance or appearance.

The MS 210-05 Standard

The MS 210-05 standard provides a structured approach to weatherability testing, ensuring consistency and reliability in test results. Adherence to this standard is crucial for manufacturers aiming to produce high-quality, durable automotive components.

Testing Procedure Overview

- Sample Preparation: Samples are conditioned to meet standard requirements.

- Exposure: Samples are subjected to controlled UV light, temperature variations, and moisture to simulate real-world conditions.

- Evaluation: Post-exposure, samples are assessed for changes in physical and aesthetic properties.

Significance of Weatherability Testing

Weatherability testing is essential for several reasons:

- Durability Assurance: Ensures materials can endure environmental conditions without degrading.

- Aesthetic Maintenance: Helps in selecting materials that retain their appearance despite exposure to harsh conditions.

- Standard Compliance: Demonstrates commitment to industry standards, enhancing market competitiveness.

Benefits of Weatherability Testing

- Product Longevity: Ensures materials last longer, reducing the need for frequent replacements.

- Enhanced Customer Satisfaction: Durable, high-quality materials lead to greater consumer trust and satisfaction.

- Cost Efficiency: Reduces long-term maintenance and replacement costs.

Weatherability Testing at Our Facility

Our facility provides comprehensive weatherability testing services, adhering strictly to the MS 210-05 standard. Our state-of-the-art equipment and experienced team ensure precise and reliable results.

Conclusion

- Adhering to MS 210-05 weatherability testing standards is crucial for the automotive industry, ensuring materials withstand environmental stress while maintaining their quality and appearance. Trust our facility to provide the rigorous testing needed to ensure your materials meet the highest standards of durability and reliability.