Wear Resistance Test

Exploring Wear Resistance Testing: Ensuring Durability in Material Performance

Introduction

- In many industries, substances are subjected to severe wear and tear because of mechanical strain, friction, and environmental elements. As a end result, put on resistance trying out has grow to be a essential technique for comparing a fabric's sturdiness and its ability to face up to the forces of abrasion, erosion, and different types of degradation over time. From automotive additives to aerospace parts, understanding a material's put on resistance is critical to ensuring its lengthy-time period performance.

What Is Wear Resistance Testing?

Wear resistance checking out measures how well a cloth can keep its structural integrity while exposed to diverse kinds of put on. Over time, substances that experience ordinary friction or abrasive forces can lose their ability to feature correctly, leading to luxurious repairs or product screw ups. By checking out for put on resistance, engineers can are expecting how lengthy a cloth will final and what situations it could cope with.

The test results assist producers pick out materials with advanced resistance to wear for packages where reliability and durability are critical.

Common Wear Resistance Test Methods

There are diverse strategies to assess a fabric’s wear resistance. Each approach simulates a specific type of wear and offers records that reflects actual-global situations. Some of the most commonplace wear resistance assessments encompass:

- Abrasion Wear Testing: This technique involves rubbing the fabric against a hard surface to simulate frictional forces. The fabric’s capacity to resist floor harm is evaluated through measuring cloth loss because of abrasion.

- Erosion Wear Testing: Erosion wear happens while debris or drinks effect a material’s floor, gradually sporting it away. Erosion testing determines how a material withstands those forces, making it especially useful in industries like oil and gas or mining.

- Adhesive Wear Testing: When two substances slide in opposition to each different, adhesive wear may also occur. This check evaluates the cloth’s resistance to floor damage due to material switch between contacting surfaces.

- Impact Wear Testing: Designed for materials that undergo repetitive influences, including in mining or heavy machinery, this take a look at assesses how well the cloth can cope with repeated blows without massive degradation.

Why Wear Resistance Testing Is Important

Wear resistance checking out performs a vital position in selecting materials for precise programs. The number one purpose is to make certain that materials can bear prolonged exposure to friction, abrasion, or erosion with out dropping their structural integrity. Several industries closely rely on put on-resistant substances, together with:

- Construction: Equipment and equipment utilized in production are continuously subjected to wear. Ensuring that those materials face up to wear means stepped forward protection and reduced downtime.

- Aerospace: High-performance components like turbine blades and touchdown gears are exposed to excessive mechanical strain, requiring substances with advanced wear resistance.

- Automotive: Brake pads, bearings, and gears have to withstand regular friction, and materials that resist put on provide better overall performance and protection.

How Is Wear Resistance Testing Conducted?

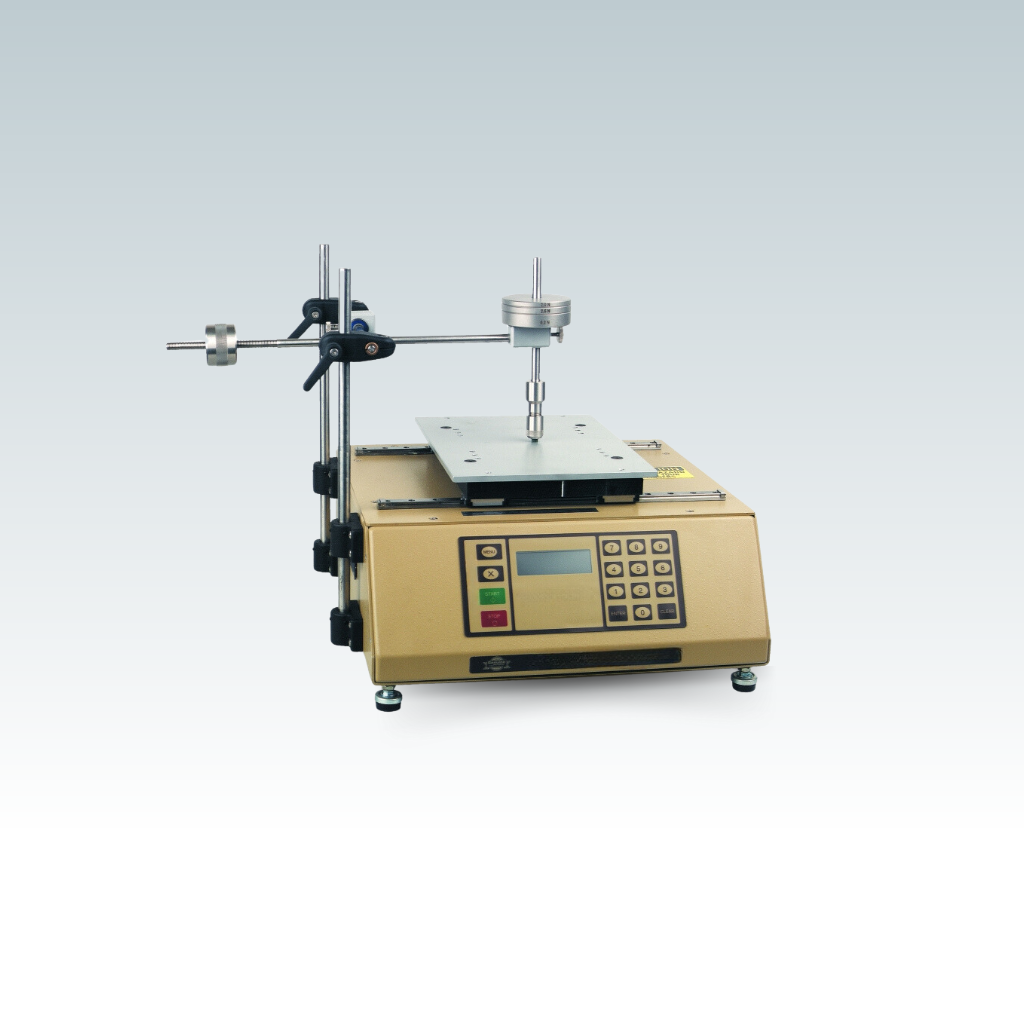

Wear resistance assessments are usually conducted the use of system designed to simulate real-lifestyles situations in which materials experience wear. Depending at the sort of put on being tested, those methods can contain abrasive surfaces, high-speed affects, or the advent of particulate matter to mimic erosion.

For instance:

- Pin-on-Disk Test: In this check, a pin made from the check fabric is pressed against a rotating disk. The ensuing friction mimics the wear due to sliding touch, presenting valuable data on the fabric’s put on price.

- Taber Abrasion Test: This broadly used approach includes rotating a specimen in opposition to an abrasive wheel. The material loss is measured to evaluate the fabric’s capability to withstand surface damage.

- Cyclic Erosion Test: A stream of liquid or stable debris is directed on the fabric’s surface to simulate erosion. This technique is regularly used in industries where additives are uncovered to harsh environmental situations.

Key Factors Influencing Wear Resistance

Several elements make contributions to a cloth’s capacity to resist put on. Understanding those elements can assist engineers optimize fabric performance:

- Material Composition: Different materials show off special levels of wear resistance primarily based on their chemical structure and hardness.

- Surface Coating: Protective coatings can substantially decorate the wear resistance of substances by using decreasing friction and abrasion at the floor.

- Load and Speed: High masses or speeds all through touch can boost up put on. Wear checking out below various load and speed conditions permits manufacturers to determine the ideal working parameters for a fabric.

- Environmental Conditions: Moisture, temperature, and the presence of corrosive substances can all have an impact on how a fabric wears over the years. Testing below simulated environmental conditions ensures that substances can carry out in actual-international eventualities.

Applications of Wear Resistance Data

The statistics amassed from wear resistance testing has sizeable packages across numerous industries. This statistics facilitates manufacturers make knowledgeable selections approximately fabric choice, method optimization, and product design. It additionally facilitates predict upkeep wishes, enhancing cost performance and prolonging product existence.

For example:

- Engineers use wear resistance statistics to enhance the overall performance of excessive-friction components.

- Designers follow the consequences to expand longer-lasting merchandise.

- Manufacturers rely upon those exams to make sure that their substances meet industry standards for durability and reliability.

Conclusion

- Wear resistance trying out is an invaluable device within the development and choice of materials for a extensive variety of industries. By evaluating a cloth's ability to withstand put on, groups can ensure that their products will maintain their performance and reliability, even inside the most demanding conditions.