Tensile Specimen Preparation As Per ASTM D638 and ISO 527

Reliable Tensile Specimen Preparation in Chennai – Compliant with ASTM D638 and ISO 527

Introduction

- In the world of materials testing, tensile specimen preparation is the critical first step that defines the accuracy and credibility of your test results. For industries and labs in Chennai, working with a trusted testing partner like Kiyo R&D Center and Laboratory ensures that your specimens meet the stringent requirements of both ASTM D638 and ISO 527 standards.

The Importance of Proper Tensile Specimen Preparation

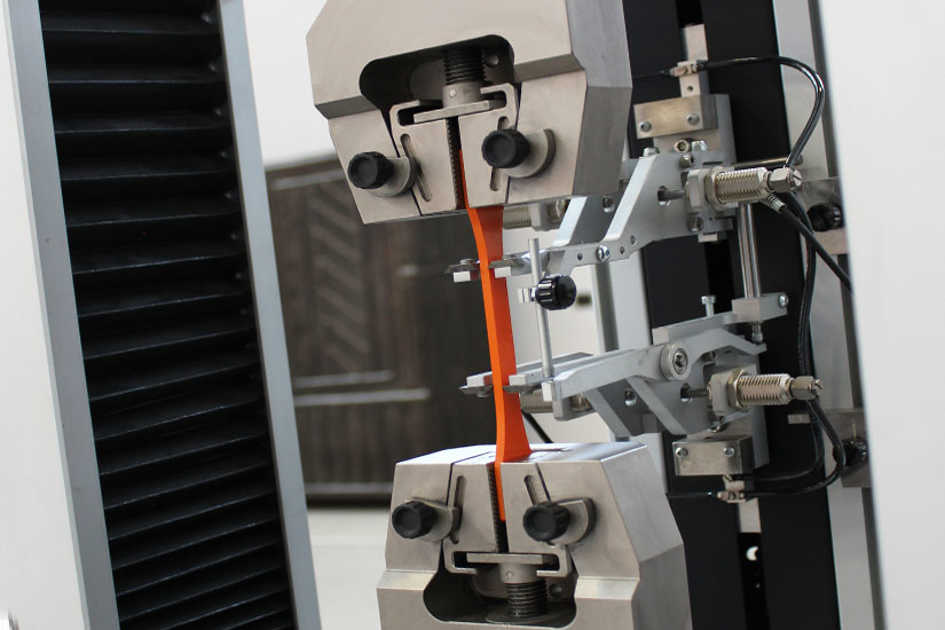

Whether you’re testing plastics, rubber, or composites, tensile testing provides key mechanical properties such as ultimate tensile strength, elongation, and modulus. However, the value of this data depends entirely on the quality of the specimen preparation. Poorly prepared specimens can yield inaccurate results, leading to potential product failure or costly redesigns.

That’s why at Kiyo R&D Center in Chennai, we offer specialized tensile specimen preparation services tailored to conform strictly with ASTM D638 and ISO 527.

ASTM D638 – U.S. Standard for Plastic Tensile Testing

The ASTM D638 standard is widely used across the plastics industry for evaluating the tensile properties of unreinforced and reinforced plastics. It details:

Specimen dimensions (Types I–V)

Standardized gauge lengths

Required test speeds

Environmental conditions for testing

At Kiyo R&D Center, we prepare specimens using precision CNC machining and die-cutting tools, ensuring dimensional accuracy and a high-quality surface finish that aligns with ASTM D638 standards.

ISO 527 – International Standard for Plastic Materials

ISO 527 serves as the globally accepted standard for determining tensile properties of plastics. It differs from ASTM D638 in specimen dimensions, types (typically Type 1A), and test speed definitions, especially for materials with high elongation at break.

We maintain strict control over environmental factors, specimen geometry, and cutting techniques to ensure all ISO 527 requirements are consistently met for international testing and compliance.

Why Chennai Trusts Kiyo R&D Center for Tensile Specimen Preparation

Chennai’s booming industrial sector—spanning automotive, polymer, defense, and electronics—relies heavily on reliable material testing. At Kiyo R&D Center and Laboratory, we are known for our:

Precision-cut tensile specimens

Strict adherence to ASTM D638 and ISO 527

Quality assurance through inspection and calibration

Transparent process documentation and traceability

Our Tensile Specimen Preparation Workflow

Here’s how our process ensures accuracy and repeatability:

- Material Selection & Preconditioning – Based on standard requirements.

- Specimen Machining – Using calibrated dies or CNC routers.

- Surface Smoothing – Preventing stress concentration during testing.

- Dimension Verification – Using calibrated tools to confirm standard compliance.

- Labeling & Logging – For traceability and compliance reporting.

Each step is governed by our internal quality protocols, ensuring that your specimens are test-ready and results are consistent.

Serving Multiple Industries with Confidence

Our tensile specimen preparation services are utilized across sectors such as:

Automotive component testing

Aerospace material verification

Packaging durability testing

Consumer product safety analysis

From small-scale prototypes to high-volume batch testing, Kiyo R&D Center ensures each specimen is crafted to perfection.

Conclusion

- If you’re seeking tensile specimen preparation in Chennai that complies with the stringent standards of ASTM D638 and ISO 527, Kiyo R&D Center and Laboratory is your trusted solution. We bring together technical expertise, advanced equipment, and a commitment to quality to support your product development and research needs.