Impact Resistance Test in Chennai

Building Stronger Futures: The Role of Impact Resistance Testing in Chennai’s Industries

Introduction

- In a city like Chennai, where industries thrive on innovation and performance, materials are the unsung heroes. Whether it's automotive parts navigating rugged roads or plastic enclosures shielding electronics from accidental drops, the ability to withstand sudden force is crucial. This is where Impact Resistance Testing becomes a game-changer.

The Science Behind the Strength

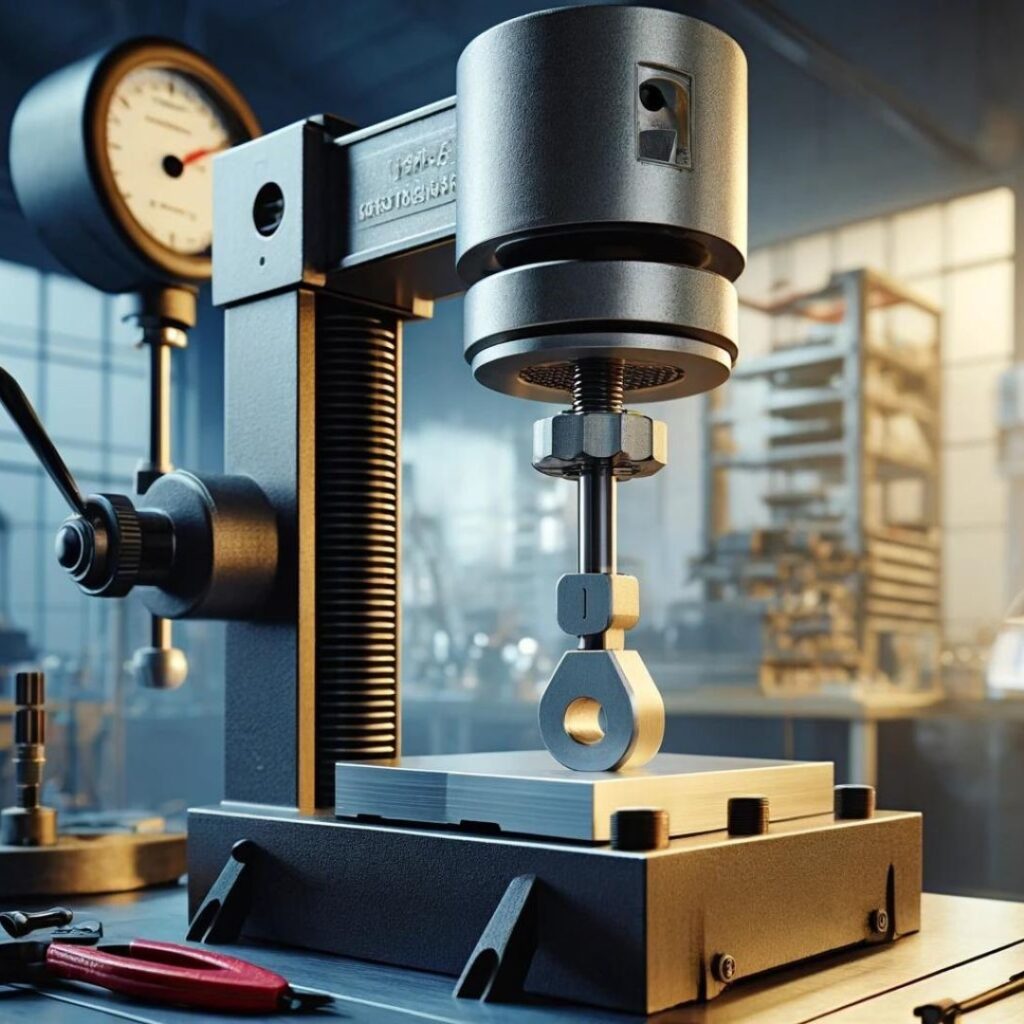

Impact resistance testing measures how well a material can endure a high-rate load without breaking or deforming. Using standardized tests like the Charpy and Izod, laboratories simulate real-world impacts to quantify toughness. These tests help determine the suitability of materials for high-stress applications and safety-critical components.

Chennai’s Need for Resilient Materials

With Chennai being a powerhouse for automotive, electronics, and manufacturing industries, demand for tested and trusted materials is at an all-time high. Manufacturers here rely on rigorous testing to:

Maintain global quality benchmarks

Reduce warranty claims and failure rates

Innovate with new lightweight or sustainable materials

Meet growing expectations for durability and safety

Why Partner with a Local Lab?

Choosing a local impact testing lab in Chennai offers significant advantages:

Faster turnaround for testing and reporting

On-site technical support and consultation

Compliance with international standards (ASTM, ISO)

Expert analysis tailored to industry-specific needs

Moreover, collaboration with a nearby lab can speed up the R&D cycle, helping businesses bring new products to market faster.

Elevating Product Trust

- For consumers, impact resistance isn’t just a technical specification—it’s peace of mind. When a product passes stringent impact tests, it reflects the brand’s commitment to quality, safety, and customer satisfaction. This testing helps manufacturers in Chennai stand out in competitive markets by reinforcing trust in their products.