Surface Resistivity Testing As per IS 3396

Why Surface Resistivity Testing Matters: A Deep Dive into IS 3396 Standards

Introduction

- In today’s fast-evolving industries—from electronics and automotive to packaging and defense—material performance and safety are more critical than ever. One essential property that engineers and manufacturers must evaluate is surface resistivity. For Indian industries, this is standardized under the IS 3396 testing protocol. At Kiyo R&D Center & Laboratory, we offer certified Surface Resistivity Testing as per IS 3396, helping manufacturers ensure their materials perform reliably in real-world conditions.

⚡ Understanding Surface Resistivity

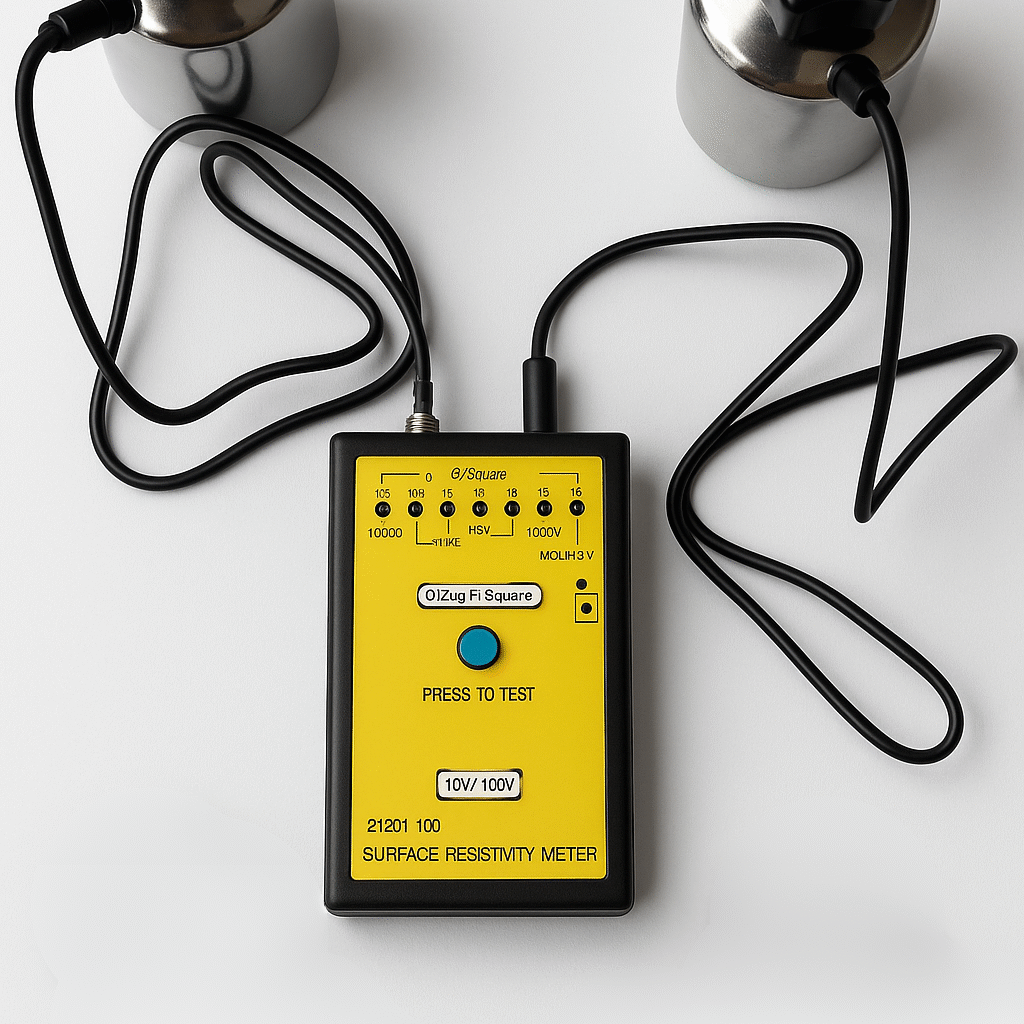

Surface resistivity is a measure of how well a material resists electrical current flowing across its surface. The results are typically expressed in ohms per square (Ω/□) and help classify materials into:

Insulative materials (≥ 10¹² Ω/□)

Static dissipative materials (10⁵ to 10¹¹ Ω/□)

Conductive materials (≤ 10⁴ Ω/□)

These values are crucial in preventing electrostatic discharge (ESD), which can damage sensitive components in electronics and create safety hazards.

📘 What Does IS 3396 Define?

IS 3396, established by the Bureau of Indian Standards (BIS), outlines the method for determining surface resistivity in solid electrical insulating materials, primarily those made of plastic, rubber, or polymer composites.

It includes guidelines for:

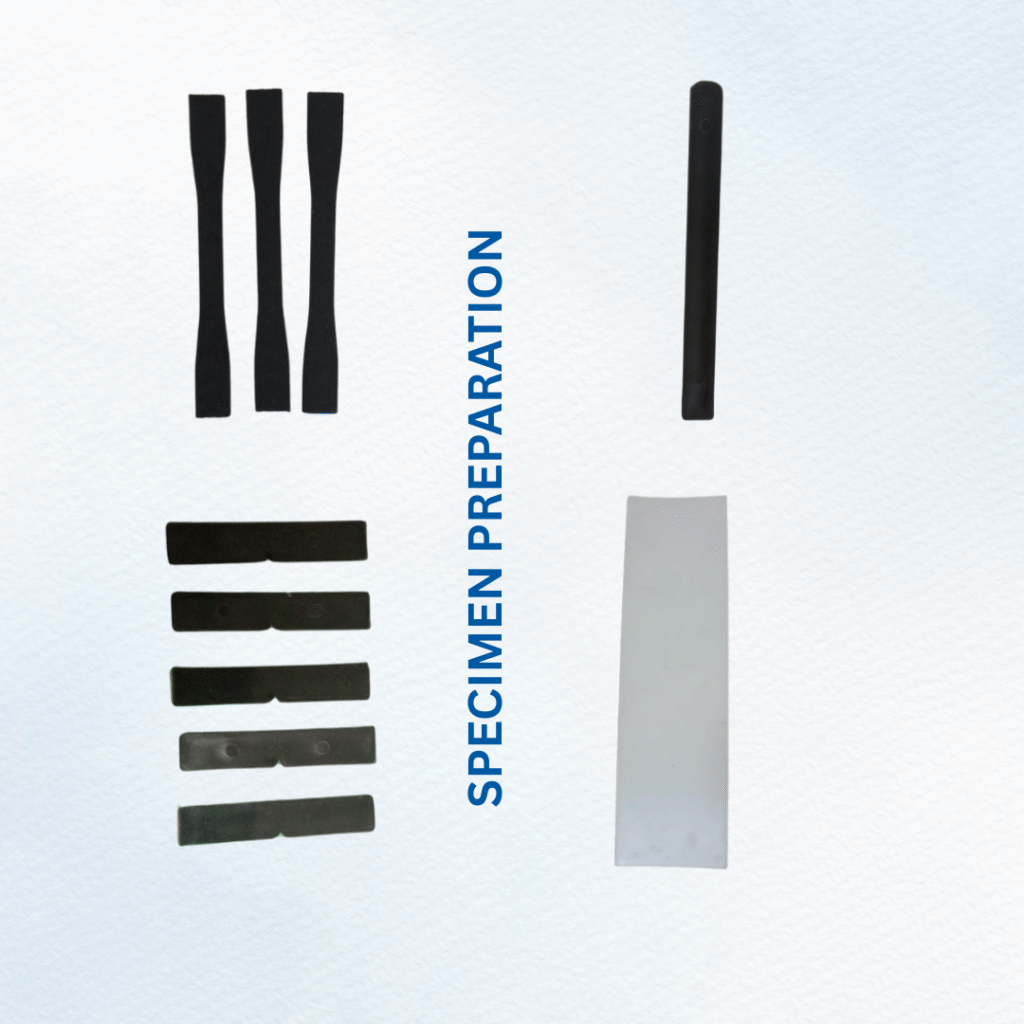

Sample preparation

Test electrode configuration

Voltage application

Environmental controls such as humidity and temperature

At Kiyo, we strictly follow these parameters to ensure repeatable and compliant test results.

🧪 Industries That Rely on Surface Resistivity Testing

Surface resistivity testing is indispensable for several applications, including:

Electronics manufacturing – for PCBs, connectors, and enclosures

Automotive interiors – ensuring safety from static shocks

Packaging materials – especially for ESD-sensitive components

Flooring and mats – in cleanrooms and control panels

Defense equipment – where insulation properties are mission-critical

🧰 Kiyo’s Testing Highlights

At Kiyo R&D Center & Laboratory, our Surface Resistivity Testing includes:

High-precision measurement instruments

IS 3396-compliant procedures

Detailed test reports with interpretation

Quick turnaround for development and compliance needs

We help clients meet both national and global product requirements while maintaining quality, consistency, and safety.

✅ Partner With Experts You Can Trust

- Surface resistivity isn't just a number—it's a vital indicator of how your materials will behave in sensitive environments. With our ISO-compliant testing infrastructure, experienced technicians, and a commitment to quality, Kiyo ensures your materials are thoroughly evaluated and certified for real-world use.