Plastic Testing Laboratory Services in chennai

Engineered to Endure: Why Kiyo R&D Lab is the Premier Plastic Testing Laboratory Services in India

Plastics are the invisible backbone of modern life. They make our cars lighter, our electronics safer, and our packaging more efficient. But plastics are complex—they are not a single, simple material. They are customized composites whose performance hinges entirely on their precise formulation and structural integrity. If a plastic housing cracks under vibration, or a polymer seal fails under heat, the problem traces back to a fundamental flaw that was missed in the testing phase.

For every engineer, manufacturer, and designer working with polymers in India, ensuring the quality, compliance, and longevity of these materials is non-negotiable. That’s why having a reliable, NABL-accredited partner is essential. Kiyo R&D Lab is the premier plastic testing laboratory services in India, offering comprehensive, integrated testing solutions designed to eliminate guesswork and guarantee your product’s endurance against real-world demands.

The Complex World of Polymers: Why Testing is Crucial

Plastics and polymers are highly sensitive to their environment, their processing method, and their additive content. A plastic component might be perfectly strong when first molded, but can rapidly degrade due to external factors.

The Consequences of Untested Plastics:

- Safety Hazards: Failure in electrical insulation, fuel lines, or medical device casings.

- Warranty Claims: Plastics failing prematurely due to UV damage, heat, or fatigue.

- Reputational Damage: Products melting, breaking, or discoloring, leading to rapid loss of consumer trust.

- Non-Compliance: Inability to secure mandatory certifications (like BIS for the Indian market or CE for export) due to unverified material properties.

To ensure your material delivers its promised performance, you need a holistic testing approach—a core offering of plastic testing laboratory services in India.

The Four Pillars of Testing at Kiyo R&D Lab

What distinguishes Kiyo R&D Lab as a top-tier plastic testing laboratory services in India is our ability to characterize polymers across mechanical, thermal, chemical, and compositional dimensions under one roof.

Pillar 1: Mechanical Properties (Strength and Durability)

We verify the physical integrity of your plastics under various loads:

- Tensile Strength & Elongation: Measures the force required to stretch the material before it breaks, and how far it stretches. Critical for films, fibers, and structural parts.

- Impact Resistance: Determines the material’s toughness—its ability to absorb a sudden blow without shattering (e.g., Izod and Charpy tests). Essential for protective casings and automotive bumpers.

- Flexural Testing: Measures the material’s bending stiffness and resistance to deformation under flexural stress.

- Fatigue & Creep Testing: The ultimate durability tests, simulating years of repeated stress (fatigue) and long-term deformation under constant load (creep).

Pillar 2: Thermal Analysis (Heat and Stability)

We determine the material’s operational limits under high temperatures:

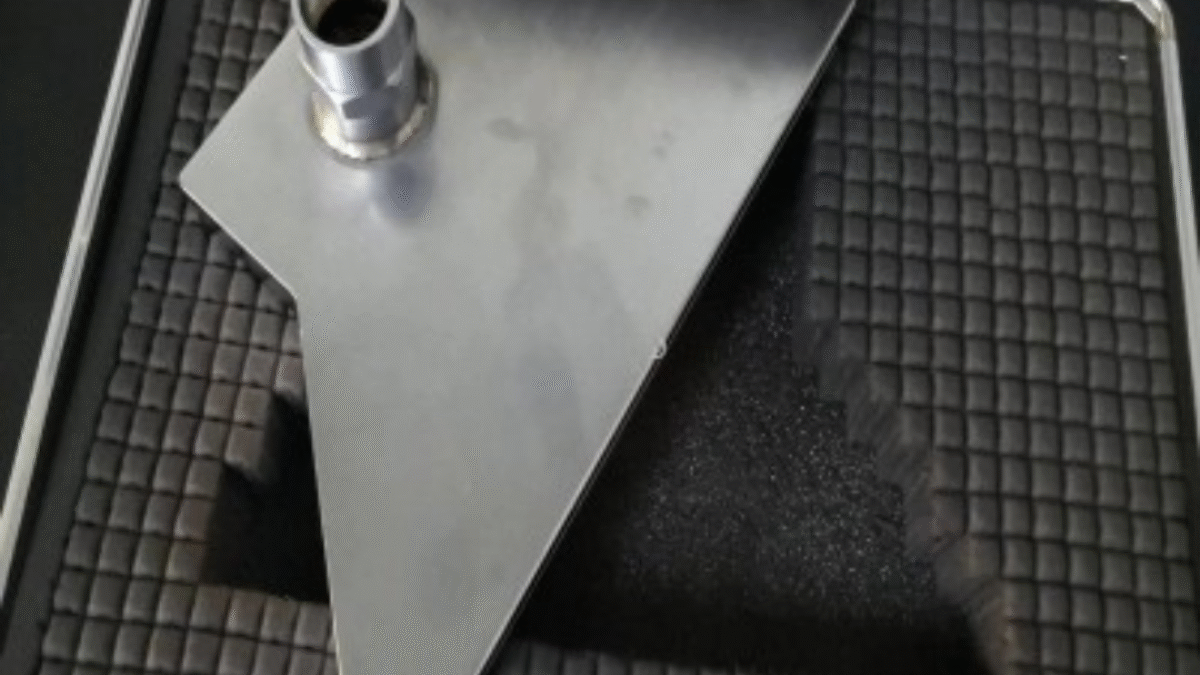

- TGA (Thermogravimetric Analysis): Measures weight loss during heating. Used to determine the precise percentage of polymer content, inorganic fillers (like glass fiber or carbon black), moisture, and volatile additives. Crucial for quality control and reverse engineering.

- DSC (Differential Scanning Calorimetry): Identifies critical thermal transition points like melting temperature (Tm) and Glass Transition Temperature (Tg). This data is essential for setting safe processing temperatures during manufacturing.

- HDT/VSP (Heat Deflection/Vicat Softening Temperature): Measures the temperature at which the plastic softens under a specific load, defining the maximum service temperature for structural applications.

Pillar 3: Chemical & Environmental Resistance

We test how your material reacts to external environmental stressors:

- Chemical Resistance Testing: Exposing plastics to oils, fuels, coolants, acids, and common cleaning agents to prevent swelling, cracking, and Environmental Stress Cracking (ESC).

- Flammability Testing: Essential safety tests (e.g., UL 94 standards) to measure how plastics burn, confirming compliance for electronics and automotive interiors.

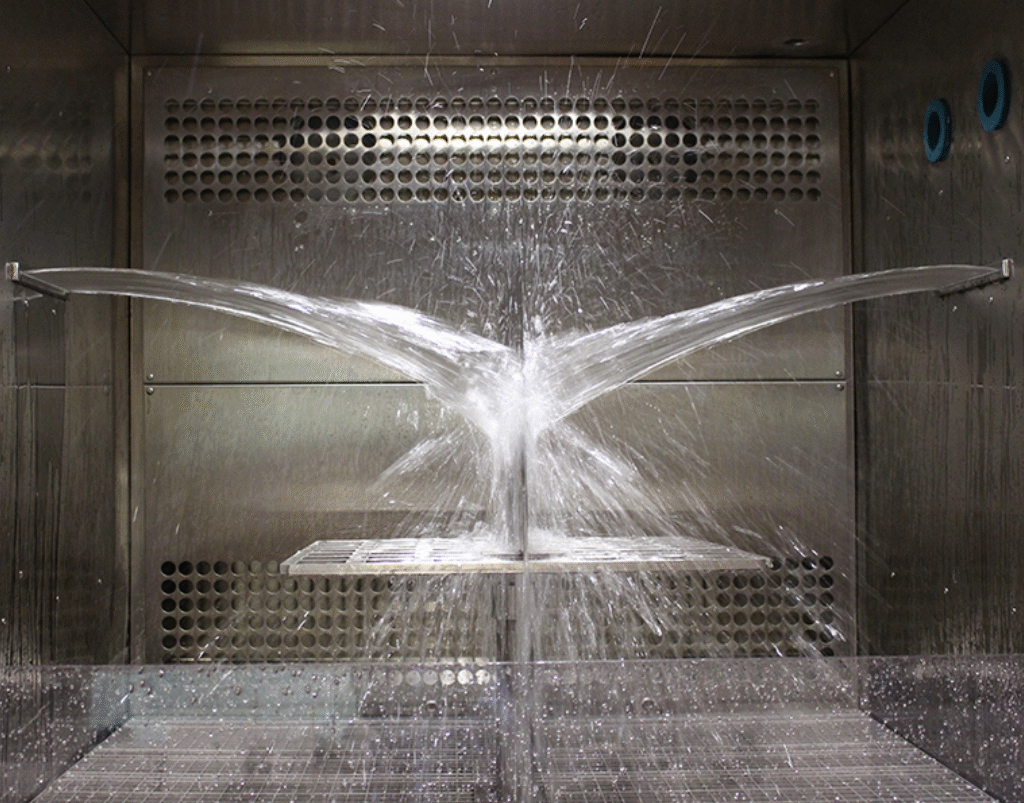

- Weatherability & UV Aging: Simulating years of outdoor exposure (sunlight, humidity, rain) in accelerated chambers to predict how plastics will hold their color, strength, and structural integrity.

Pillar 4: Analytical Characterization

We identify the material itself using spectroscopy:

- FTIR (Fourier-Transform Infrared Spectroscopy): Quickly identifies the polymer type (e.g., PVC vs. ABS) and detects the presence of contaminants or unknown material mixes.

Why Kiyo R&D Lab is the Trusted Partner in India

When dealing with the complexity of polymers, mere competence is not enough; you need verified authority and comprehensive support. Kiyo R&D Lab delivers this confidence:

1. NABL / ISO 17025 Accreditation: Global Standard

Kiyo R&D Lab is NABL-accredited (ISO/IEC 17025). This is the highest assurance of technical competence and quality management. When you receive reports from our plastic testing laboratory services in India, you are receiving data that is traceable, reproducible, and accepted by regulators and international clients globally.

2. Expert Material Scientists and Failure Analysis

Our team consists of specialized material chemists and engineers who focus solely on polymers and related materials. We don’t just run the test and send a number; we provide consultative failure analysis, helping you understand why a material failed (e.g., incorrect filler loading, wrong processing temperature) and guiding you toward the optimal corrective action.

3. Integrated, Efficient Testing Solutions

Our ability to perform mechanical, thermal, and chemical testing under one accredited roof allows for seamless integration. This saves clients time and logistics costs, supporting agile research and rapid quality control checks essential for industries like the thriving Indian automotive and electronics sectors.

Conclusion: Eliminate Risk. Guarantee Polymer Performance.

In an industry reliant on material integrity, investing in expert testing is the smart move that protects your brand and your customers. Relying on supplier datasheets without independent verification is a massive business risk.

By partnering with Kiyo R&D Lab—the leading plastic testing laboratory services in India—you gain verifiable proof that your materials are consistently formulated, structurally sound, and engineered to endure the full spectrum of operational demands.

Ready to ensure your plastics are engineered to endur? Contact Kiyo R&D Lab today to discuss your polymer testing requirements.