In today’s demanding industrial environment, materials are expected to perform reliably under sudden loads, shocks, and extreme service conditions. Whether it is an automotive component, a plastic housing, a metal part, or a composite structure, understanding how a material behaves under impact is critical. This is where Charpy and Izod impact testing play a vital role.

At Kiyo R&D LAB, we provide professional and reliable Charpy Izod impact test services in India, helping manufacturers, R&D teams, and quality engineers evaluate material toughness and fracture behavior with confidence.

Kiyo R&D LAB offers reliable impact test services across India.

Why Impact Testing Is Important

Impact testing measures a material’s ability to absorb energy during sudden loading or shock. Unlike tensile or compression tests that apply gradual force, impact tests simulate real-life sudden failures such as drops, collisions, or sudden mechanical stress.

These tests help determine:

- Material toughness and brittleness

- Resistance to sudden fracture

- Performance at different temperatures

- Suitability for safety-critical applications

Industries such as automotive, aerospace, electrical, construction, packaging, and consumer goods rely heavily on impact test data to ensure product reliability and user safety.

Understanding Charpy and Izod Impact Tests

Charpy Impact Test

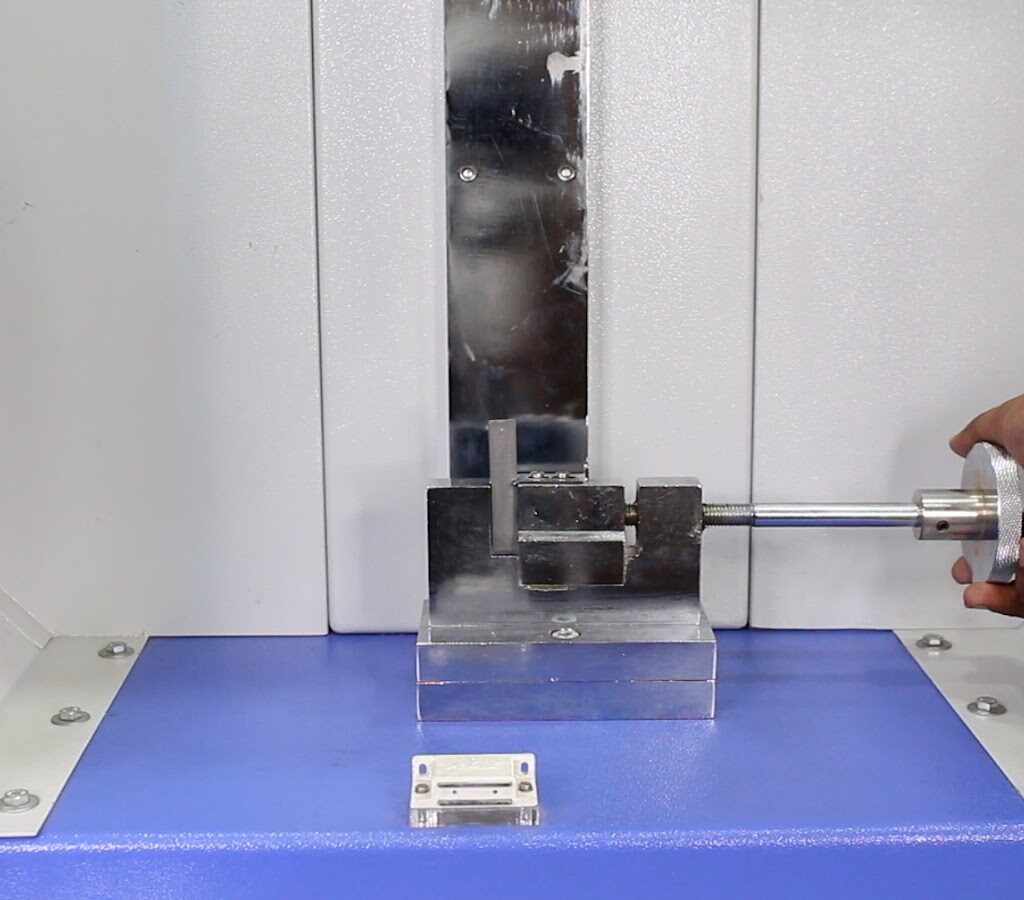

The Charpy test measures the energy absorbed by a notched specimen when it is struck by a pendulum hammer. The specimen is supported horizontally, and the notch faces away from the striking edge.

This test is widely used for:

- Metals and alloys

- Plastics and polymers

- Composite materials

It helps determine material behavior under high strain-rate loading conditions.

Izod Impact Test

In the Izod test, the specimen is held vertically like a cantilever beam, and the pendulum strikes the notched side of the sample.

Izod testing is commonly used for:

- Plastics and polymer materials

- Quality control during production

- Comparison of material grades

Both Charpy and Izod tests provide critical insights into impact resistance, helping engineers select suitable materials for real-world applications.

Why Choose Kiyo R&D LAB for Charpy Izod Impact Testing?

Kiyo R&D LAB is a trusted name in material testing, offering precise and repeatable Charpy Izod impact test services in India. Our laboratory combines technical expertise, calibrated equipment, and strict procedural control to deliver reliable results.

What Makes Us Different?

- Accurate & Repeatable Testing

Our impact testing machines are calibrated and maintained to ensure consistent results. - Experienced Technical Team

Skilled professionals interpret results beyond numbers, helping clients understand material behavior. - Compliance with Global Standards

Testing performed as per ASTM, ISO, and IS standards. - Fast Turnaround Time

Efficient workflows ensure timely delivery of test reports. - Clear & Professional Reports

Easy-to-understand reports suitable for audits, certifications, and customer submissions.

Charpy & Izod Impact Testing Services We Offer

At Kiyo R&D LAB, we provide a comprehensive range of impact testing services, including:

1. Charpy Impact Testing

- Notched and unnotched specimens

- Room temperature and low-temperature testing

- Energy absorption measurement

- Fracture behavior analysis

2. Izod Impact Testing

- Notched Izod impact testing

- Plastic and polymer materials testing

- Quality control and batch validation

3. Plastic and Polymer Impact Testing

- Thermoplastics and thermosets

- Filled and reinforced polymers

- Engineering plastics and blends

4. Metal Impact Testing

- Ferrous and non-ferrous metals

- Welded joints and heat-treated samples

- Structural and industrial components

Standards Followed at Kiyo R&D LAB

Our Charpy and Izod impact test services in India are conducted as per recognized national and international standards, including:

- ASTM E23 – Impact Testing of Metallic Materials

- ASTM D256 – Izod Impact Resistance of Plastics

- ASTM D6110 – Charpy Impact Resistance of Plastics

- ISO 179 – Plastics — Charpy impact test

- ISO 180 – Plastics — Izod impact test

- IS standards as applicable

All testing activities are performed under controlled conditions using calibrated equipment to ensure accuracy and traceability.

Applications of Charpy and Izod Impact Testing

Our impact testing services support a wide range of industries, including:

- Automotive and EV components

- Electrical and electronic housings

- Plastic molded products

- Consumer goods and appliances

- Construction and infrastructure materials

- Research and development laboratories

These tests help manufacturers evaluate product safety, durability, and compliance before market release.

Importance of Impact Testing in Quality Control

Impact testing plays a critical role in quality assurance by:

- Identifying brittle failure risks

- Ensuring consistency across production batches

- Supporting material selection decisions

- Validating supplier materials

- Meeting regulatory and customer requirements

At Kiyo R&D LAB, we ensure every test result adds real value to your quality process.

Why Industries Trust Kiyo R&D LAB

- NABL-aligned testing practices

- Modern instrumentation and facilities

- Skilled and experienced technical staff

- Transparent and traceable reporting

- Customer-focused technical support

Our goal is not just to test samples but to help industries build safer, stronger, and more reliable products.

Kiyo R&D LAB offers reliable impact test services across India.

Partner with Kiyo R&D LAB

If you are looking for accurate and dependable Charpy Izod impact test services in India – Kiyo R&D LAB is your trusted testing partner. From routine quality checks to advanced material evaluation, we support your testing needs with professionalism and precision.

Contact us today to discuss your testing requirements and experience reliable material testing services you can trust.