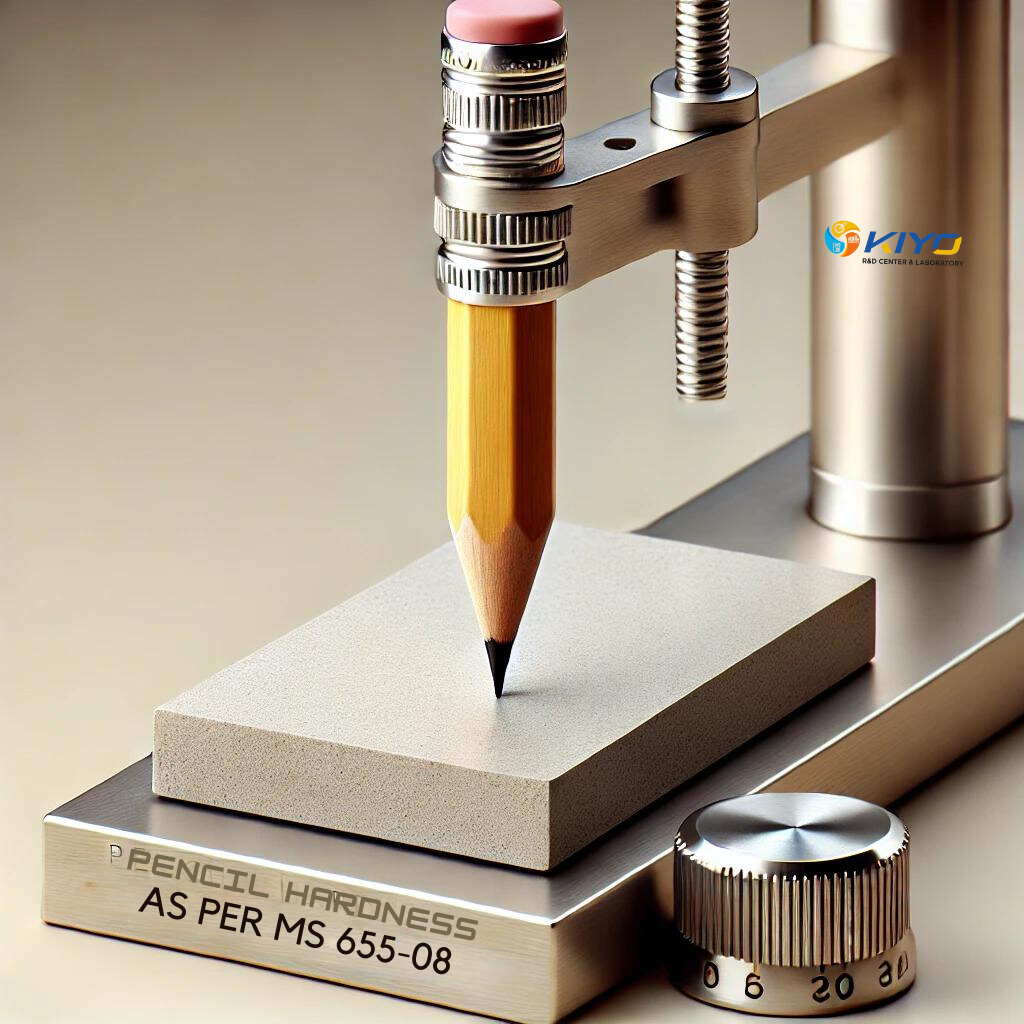

Pencil Hardness as per Standard MS 655-08

Pencil Hardness Testing: Ensuring Coating Durability

Introduction to Pencil Hardness Testing:

- Pencil hardness testing is a vital technique used to evaluate the hardness of a coating on a material's surface. This method, known as the Wolff-Wilborn test, utilizes graphite pencils with different hardness levels to determine the coating's resistance to scratching. Adhering to standards such as ASTM D3363, ISO 15184, and MS 655-08, this test is crucial for ensuring the quality and durability of coatings.

Test Methodology: The pencil hardness test is straightforward yet effective, involving several key steps:

- Surface Preparation:

- Ensure the test surface is clean, smooth, and dry.

- Use a set of pencils with hardness ranging from 6B (softest) to 6H (hardest).

- Instrument Setup:

- An adjustable pencil hardness tester is used to facilitate the test.

- The tester allows the application of three different weights: 500g, 750g, and 1000g.

- Conducting the Test:

- Position the pencil at a 45-degree angle to the surface.

- Apply a consistent force to move the pencil across the coating.

- Repeat the test with pencils of increasing hardness until a pencil leaves a mark on the coating.

- Result Evaluation:

- Identify the hardest pencil that does not scratch the surface.

- Record the hardness value as the coating’s hardness rating.

Technical Specifications:

- Angle: The pencil is held at a precise 45-degree angle to the test surface.

- Pressure: The test is performed with pressures of 500g, 750g, and 1000g, adjusted by selecting appropriate loading weights.

- Hardness Range: Pencils used in the test range from 6B to 6H, covering a wide spectrum of hardness levels.

Compliance with Standards: The pencil hardness test is conducted in accordance with several international standards to ensure accuracy and consistency. These standards include:

- ASTM D3363

- EN 13523-4

- ISO 15184

- MS 655-08

Importance of Pencil Hardness Testing: Pencil hardness testing provides a quick and reliable method for assessing the hardness of coatings. This information is crucial for industries that require high-quality and durable coatings, such as automotive, aerospace, and consumer electronics. By ensuring that coatings meet specific hardness criteria, manufacturers can enhance the performance and longevity of their products.

Conclusion:

- The pencil hardness test is a valuable tool in the quality control process for coatings. By following standardized procedures, this test provides accurate and reliable measurements of coating hardness, ensuring that products meet the required durability standards. This method is essential for maintaining high-quality coatings that can withstand wear and tear, ultimately contributing to the longevity and performance of coated materials.

FAQ

1. What range of pencil hardness is used in the test?

Pencils ranging from 6B (softest) to 6H (hardest) are used in the test to cover a comprehensive spectrum of hardness levels.

2. Why is the pencil held at a 45-degree angle during the test?

Holding the pencil at a 45-degree angle ensures consistent contact with the surface, providing accurate and repeatable results.

3. What are the key parameters of pencil hardness testing?

Key parameters include the 45-degree angle of the pencil to the test surface, applied pressures of 500g, 750g, and 1000g, and the range of pencil hardness from 6B to 6H.

4. What industries benefit from pencil hardness testing?

Industries such as automotive, aerospace, coatings, paints, and consumer electronics benefit from pencil hardness testing to ensure their products have durable and high-quality coatings.