Coating Film Thickness Testing in India

Coating Film Thickness Testing in India

Introduction

Ever wondered how thick a coating on metal, plastic, or wood really is—and if that thickness meets the promise? Whether it’s paint on a car, protective layering on electronics, or a finish on consumer goods, coating film thickness plays a silent but critical role. It determines durability, corrosion resistance, aesthetics, even safety in many cases.

That’s why coating film thickness testing in India – Kiyo R&D Lab is getting a lot of attention. More and more manufacturers, brands, auditors, and regulators are insisting that coatings be not just applied—but verified. In this blog, we’ll take a deep dive into coating film thickness testing: what it is, why it matters, how it’s done, what challenges exist in India, and why Kiyo R&D Lab is a laboratory you should seriously consider if precision matters to you.

Body

What Is Coating Film Thickness Testing?

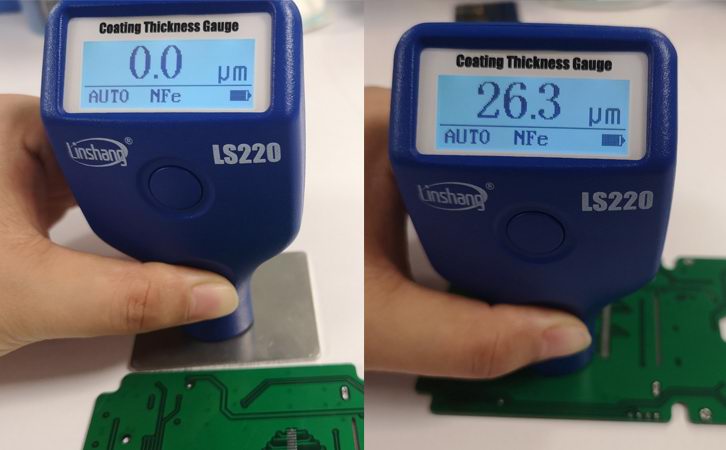

“Coating film thickness” refers to the measurement of how much coating material (paint, varnish, plating, etc.) sits on top of a substrate. It can be in micrometers (µm), mils (thousandths of an inch), or other units.

Testing that thickness means accurately quantifying how thick the coating is, to ensure:

- It meets specs (client, industrial, regulatory).

- It provides enough protection (against corrosion, wear, UV etc.).

- It’s cost‑efficient (too much coating is waste; too little fails protection).

- The finish looks right (too thin may show imperfections; too thick may crack or peel).

Why It Matters: Benefits and Risks

Here are reasons why coating film thickness testing is important, and what can go wrong without it.

Benefits:

- Quality Assurance & Compliance: Many industries (automotive, aerospace, electronics, heavy machinery, architectural coatings) have standards for how thick coatings should be. Noncompliance can lead to rejection, recalls, or legal issues.

- Longevity & Protection: Adequate coating thickness helps resist rust, corrosion, chemical attack, weathering, abrasion. Without sufficient thickness, the substrate gets exposed sooner.

- Cost Savings: Overcoating wastes material, time, labour. Undercoating leads to failures and maintenance costs. Right thickness helps balance cost & performance.

- Aesthetic & Functional Consistency: Uniform finish, consistent protection. For consumer goods, visual appeal matters; for industrial, performance matters.

- Risk Mitigation: Coating too thick or too thin can cause defects: cracking, delamination, peeling, excessive weight, process inefficiencies.

Risks / Problems When Coating Thickness is Not Measured:

- Coating fails prematurely (rust, exposure, peeling).

- Regulatory non‑compliance, especially for exports or safety‑critical items.

- Uneven finishes that reduce consumer confidence.

- Waste of resources (material, labour).

- Product recalls or warranty claims.

Common Methods of Coating Film Thickness Testing

There are several techniques used globally, many of which are practiced in India, for measuring film/coating thickness. The choice depends on the substrate, coating type, required precision, cost, and whether non‑destructive testing is needed.

Here are some of the main ones:

| Method | How It Works | Advantages | Limitations / When Not Suitable |

|---|---|---|---|

| Magnetic Induction (Magnetic Gauge) | For coatings on ferromagnetic metals (e.g., steel). Measures change in magnetic field related to thickness. | Non‑destructive, fast, relatively inexpensive. | Only works with ferromagnetic substrate; limited to certain coating types. |

| Eddy‑Current Method | For non‑magnetic coatings (paint, lacquer) on conductive substrates; uses eddy currents. | Non‑destructive; good for non‑ferrous base materials. | Need calibration; only works when substrate conductive; less accurate for very thin/multi‑layers. |

| Ultrasonic Measurement | Ultrasonic waves sent through coating, return time gives thickness. | Can measure thick, multi‑layer coatings; works for many substrate/coating types. | Equipment costly; requires good surface preparation; sometimes less accurate for very thin coatings. |

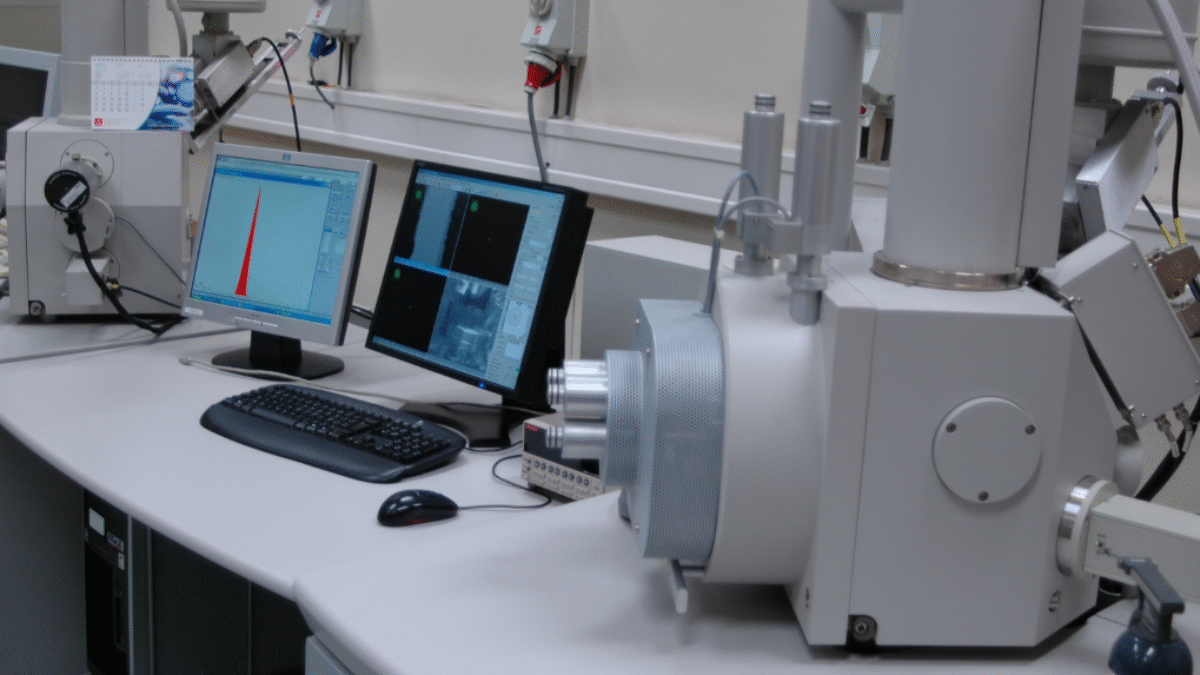

| X‑Ray Fluorescence (XRF) | Uses x‑ray excitation to measure thickness of metallic coatings or plating; can also do multi‑layers. | High precision; works for very thin metallic coatings; non‑contact. | Very expensive; not always suitable for non‑metallic coatings; safety concerns; need skilled operator. |

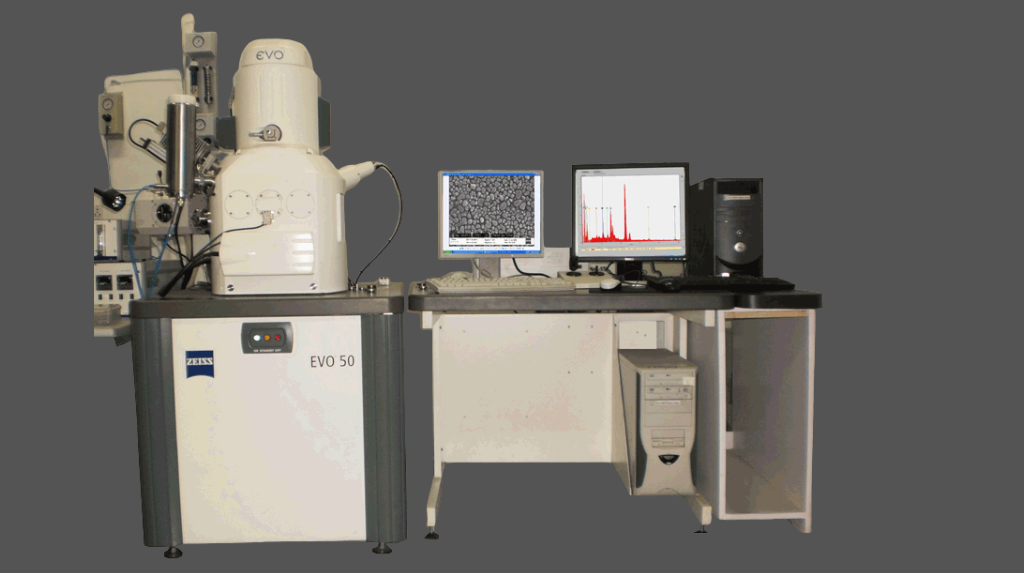

| Cross‑Sectioning / Destructive Testing | Coating + substrate cut, polished, observed under microscope to see thickness. | Very accurate; shows layering, defects, adhesion etc. | Destructive; time consuming; sample preparation intensive. |

| Gravimetric / Mass Based Methods | Based on mass of coating vs area; useful for powder or liquid coatings before curing. | Good where other methods not feasible; useful in R&D. | Less precise once cured; many assumptions; not used in every industrial QC. |

These methods are aligned with international standards (ASTM, ISO etc). For example, dry film thickness (DFT) testing often needs to follow ASTM standards. Applied Technical Services+2Fischer+2

The Testing Landscape in India

India has been rapidly growing its industrial base—automobiles, infrastructure, electronics, packaging, etc.—and coating technology is becoming more advanced. Here are some key observations about the state of coating film thickness testing in India:

- Accredited Testing Labs are present especially in big cities like Chennai, Delhi, Mumbai, Bengaluru. NABL (National Accreditation Board for Testing & Calibration Laboratories) labs are preferred because their results are accepted in regulatory, export, and industry circles. narangtestlabs.com+2Justdial+2

- Service Coverage: Many regions have labs offering plating & coating thickness services; the options increase in metros. Example labs include Narang Metallurgical & Spectro Services, VS P Testing Lab, Eurofins in Delhi, etc. narangtestlabs.com+2Eurofins+2

- Equipment & Methods: Non‑destructive methods (magnetic, eddy current, XRF) are becoming more common; destructive methods still used for verification, failure analysis, complex coatings. The labs often follow international test standards. Fischer+2Intertek+2

- Challenges: Turnaround time, cost for high‑precision methods (like XRF), uneven availability or awareness in smaller towns, calibration and operator skill gaps in some labs; sample logistics (shipping samples to lab) adds cost/time.

- Awareness & Usage Growth: As export markets and regulatory compliance become more stringent, manufacturers increasingly include coating thickness specification early in design/QA. Also, consumers want better durability, finish, environmental compliance (e.g. lead‑free, low VOC paints).

Why Choose Kiyo R&D Lab for Coating Film Thickness Testing in India

Now, let’s focus on why Kiyo R&D Lab is a strong partner if you are looking for coating film thickness testing in India – Kiyo R&D Lab. Based on available information and what labs typically offer, here are reasons they stand out (or would stand out, if these are their features; you might verify specifics with them):

- Local, Accessible Lab in Chennai

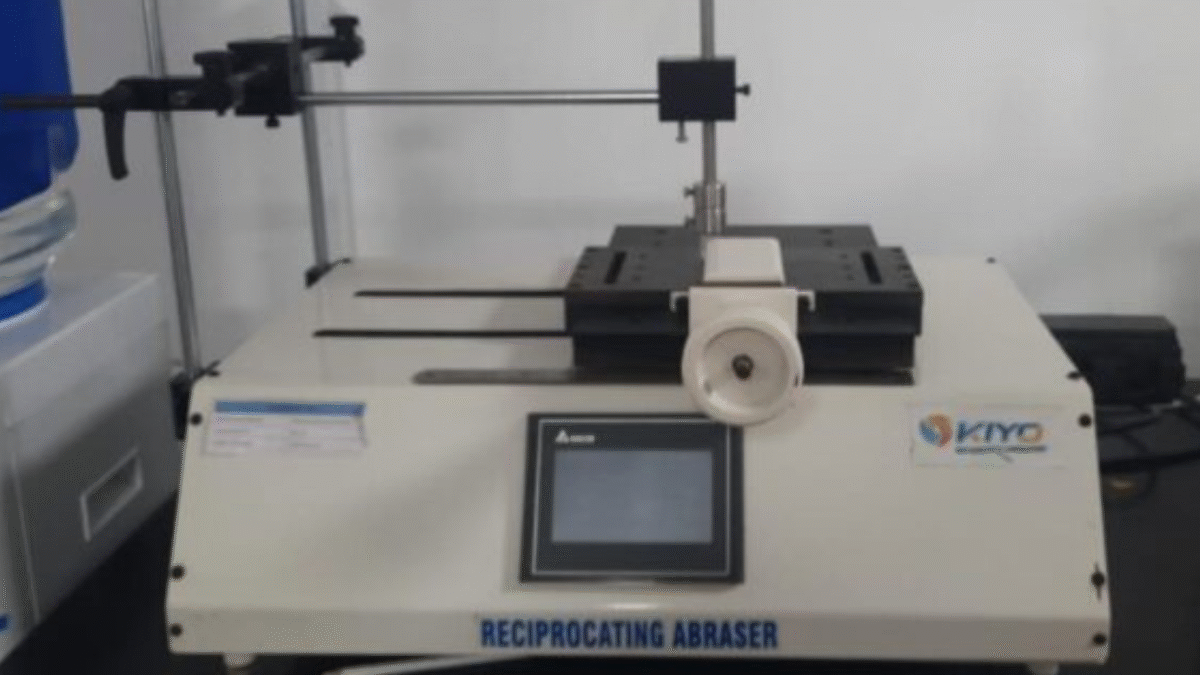

For clients in South India, having a lab like Kiyo R&D means reduced sample shipping time, lower transport‑risk, faster communication. From listings, Kiyo R&D shows up among coating thickness testing labs in Chennai (Justdial listing) with good reputation. Justdial - Range of Coating Types & Substrates

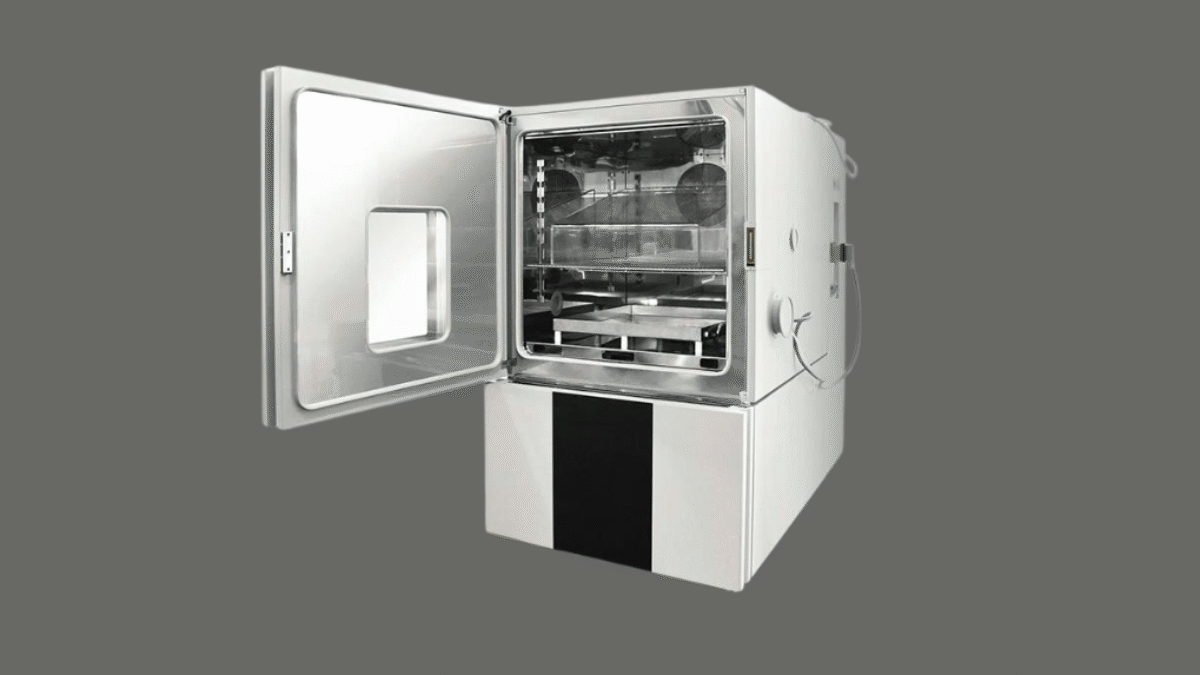

Whether it’s paint, varnish, plating, lacquers, polymers, or metals, different methods are required. A lab that can test multiple substrate‑coating combinations (e.g. metal, plastic, composites) gives you flexibility. Kiyo likely works in multiple sectors (plastics, automotive etc.). (You’d want to check exactly which substrate and coating types they support, but presence in the material testing space is promising.) - Use of Modern, Non‑Destructive & Destructive Methods

A lab that offers both (non‑destructive for fast QC; destructive/cross‑sectioning for detailed insights) is ideal. For example, magnetic, eddy current, XRF etc. If Kiyo R&D has such equipment, that gives a high level of confidence. - Accreditation / Standards Compliance

Labs accredited by NABL or following ISO/ASTM standards give you results that are more likely to be accepted by regulatory bodies, exporters, auditors. If Kiyo R&D has such credentials, that’s a strong plus. - Quality Reporting & Customer Support

Beyond listing a number, what counts is: detailed reports, calibration traceability, clarity about error margins, ability to interpret results, suggestions for improvement. If Kiyo R&D is known for responsive communication, transparent pricing, and explains limitations (e.g. measurement error, sample preparation), then you’re getting value. - Turnaround Time & Cost Balance

For many industrial clients, speed + accuracy + cost are a triad. A lab that delivers accurate coating film thickness testing without inordinate delays or exorbitant costs delivers real competitive advantage.

How to Engage / What to Ask When You Choose a Lab

If you decide to go for coating film thickness testing in India – Kiyo R&D Lab (or any lab), here are practical things you should check or ask to ensure you get what you need:

- What methods do you use for my specific substrate + coating? (Magnetic, eddy‑current, XRF, cross section etc.)

- What is the measurement range and precision? How thin or thick coatings you can measure, and what is the error tolerance.

- Are you accredited (NABL / ISO / equivalent)? Can you provide sample reports?

- Sample preparation requirements: Cleanliness, flatness, size, number of samples. The measurement method might need special prep.

- Turnaround time & cost: How many samples, how complex coatings = cost and time differences.

- Calibration & traceability: Is your equipment calibrated? Do you use certified standards?

- Report format: Will you get raw data? Will the report include tolerances, interpretation, recommendations?

- Failure analysis support: If coatings fail or seem uneven, do they help you understand “why” not just “what”?

Conclusion

If coatings are part of what makes your product look good, last long, or perform under tough conditions, then coating film thickness is not something you want to leave to guesswork. It’s a measurable, verifiable property that affects cost, durability, compliance, and brand reputation.

For manufacturers, exporters, designers, and brands in India, choosing the right lab for coating film thickness testing in India – Kiyo R&D Lab could make a big difference. The right lab will combine modern methods, accredited standards, transparency, reasonable cost, and fast turnaround. Kiyo R&D Lab appears to be a promising option, especially for those in or near Chennai, or those looking for high quality in coatings work.

Final Thoughts & Call to Action

- If you have a coating you need to test—whether for paint, plating, or specialty finishes—lay out your requirements clearly: substrate, coating material, expected thickness, tolerance, finish, regulatory or client standards.

- Reach out to potential labs with those specs and compare not just price, but what methods they’ll use, how accurate, how fast, and how clearly they’ll report.

- If you like, I can also put together a list of labs across India like Kiyo R&D Lab with details (pricing, methods, response time) so you can pick the best one. Do you want me to prepare that?

Surface Resistivity Test in Chennai

Surface Resistivity Test in Chennai

Empowering Chennai’s Industries with Surface Resistivity Testing

Introduction

- As electronic devices and advanced polymers become integral to modern manufacturing, ensuring their electrical performance is no longer optional—it’s essential. Surface resistivity testing has emerged as a critical quality control step for industries aiming to safeguard their products against electrostatic damage, contamination, and electrical failures. In Chennai, a city synonymous with industrial growth, the demand for this specialized testing is gaining momentum.

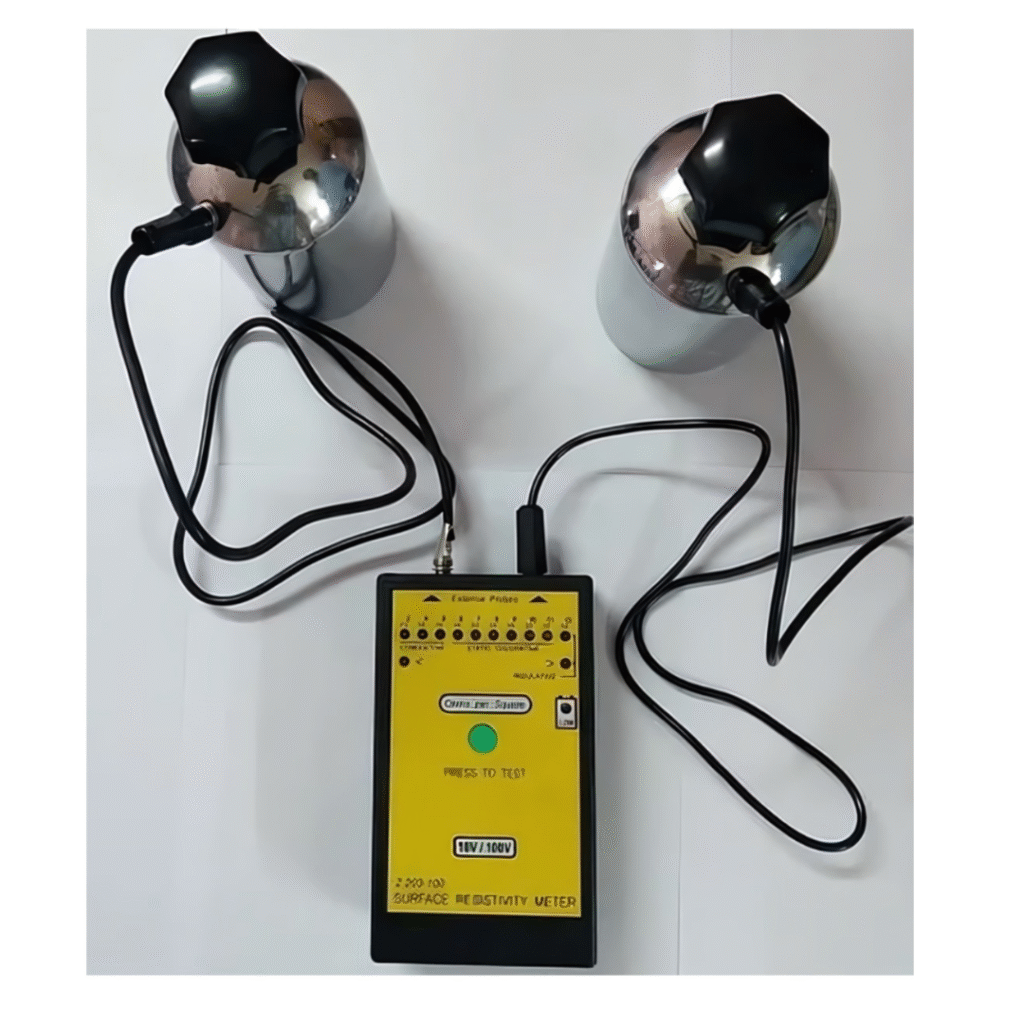

What is Surface Resistivity?

Surface resistivity refers to how much a material resists the flow of electrical current across its surface. For materials used in circuit boards, electronic housings, automotive components, and packaging, maintaining appropriate resistivity levels ensures both performance and safety. This is especially relevant in electronics manufacturing and ESD (Electrostatic Discharge) control applications.

Why Industries in Chennai Rely on This Test

Chennai is home to a diverse industrial base—from IT and electronics to automotive and aerospace. For these sectors:

-

Static protection is a top priority in sensitive manufacturing environments.

-

Material qualification must comply with international electrical insulation standards.

-

Innovation and reliability depend on accurate material behavior predictions.

Surface resistivity testing enables companies to:

-

Evaluate material consistency

-

Prevent ESD-related failures

-

Validate compliance with global regulations like ASTM D257

Leading the Way: Local Testing Excellence

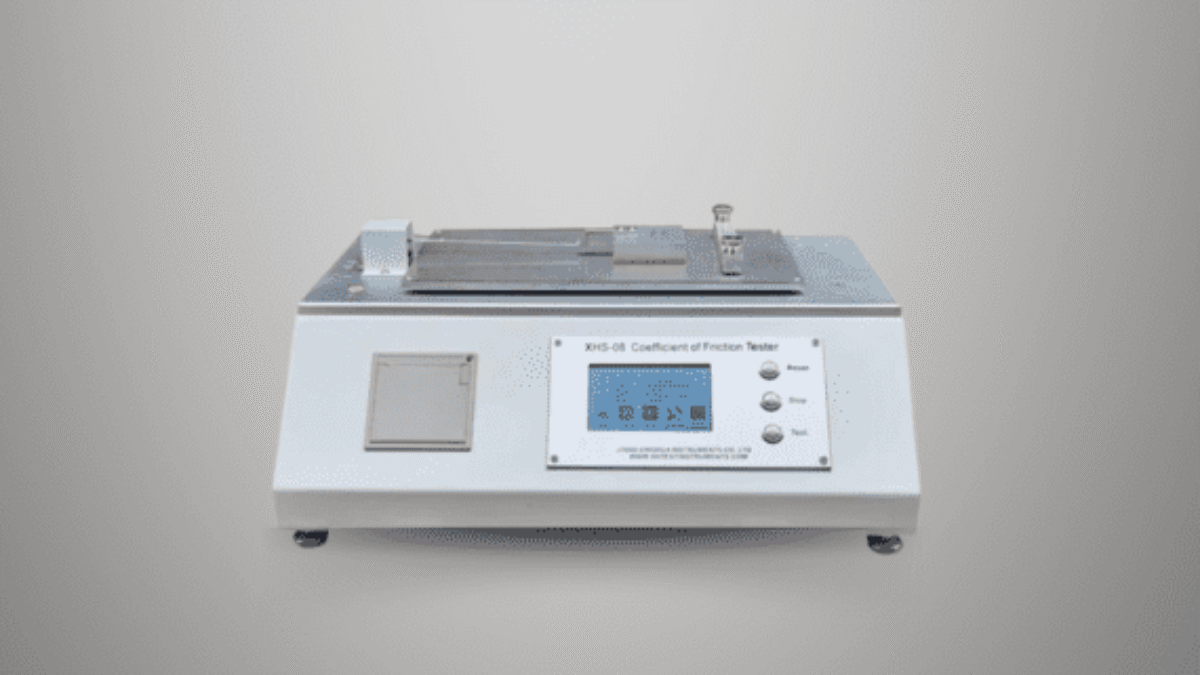

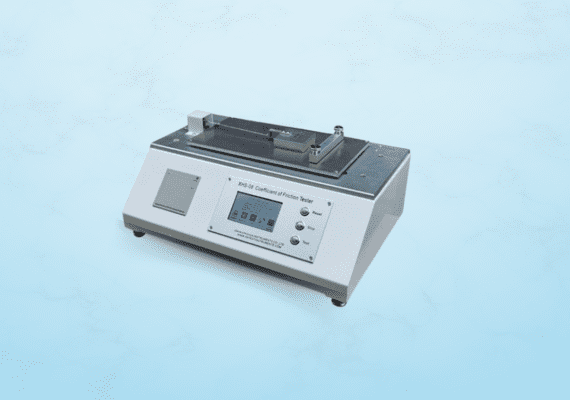

Chennai’s laboratories, like Kiyo R&D Center & Laboratory, are equipped with the latest resistivity testing systems, ensuring accurate measurement even for high-impedance materials. These labs often support:

-

Polymeric compound developers

-

Packaging material manufacturers

-

Automotive and electronics OEMs

With precise instrumentation and strict procedural standards, clients receive reliable data crucial for product design, process control, and certification.

Conclusion

- As Chennai’s manufacturing landscape continues to modernize, surface resistivity testing will become increasingly integrated into routine material assessments. Companies prioritizing this analysis gain a competitive edge—offering safer, more durable, and regulation-compliant products.

FAQ

What standards are used in surface resistivity testing?

A: The most widely followed standards include ASTM D257 and IEC 60093, which define procedures and testing conditions for reliable measurement.

How long does it take to get test results in Chennai?

A: Turnaround time varies by lab and project scope but typically ranges from 3 to 7 business days. Priority testing may be available upon request.

Can surface resistivity testing be customized for specific applications?

A: Yes, many labs offer tailored test setups to match your environmental, voltage, or humidity conditions, particularly for R&D or product qualification.