Gloss as per Standard MS 300-55

The Significance of Gloss in Material Testing: A Deep Dive into Standard MS 300-55

Introduction

- Gloss is a pivotal characteristic in the world of materials testing, influencing both the aesthetic and functional attributes of products. Standard MS 300-55 sets the benchmark for gloss measurement, ensuring precision and consistency across various materials. This blog explores the importance of gloss, the methodology outlined in the standard, and its application in different industries.

Understanding Gloss

Gloss refers to the ability of a surface to reflect light in a mirror-like manner. This property is essential in determining the visual appeal of products, making it a critical parameter in industries such as automotive, consumer electronics, and home appliances. The level of gloss can range from high (shiny) to low (matte), each serving different purposes and preferences.

Key Elements of Standard MS 300-55

- Scope and Relevance: Standard MS 300-55 is applicable to a wide array of materials, including but not limited to plastics, metals, and coatings. It provides a universal approach to gloss measurement, ensuring consistency in quality control processes.

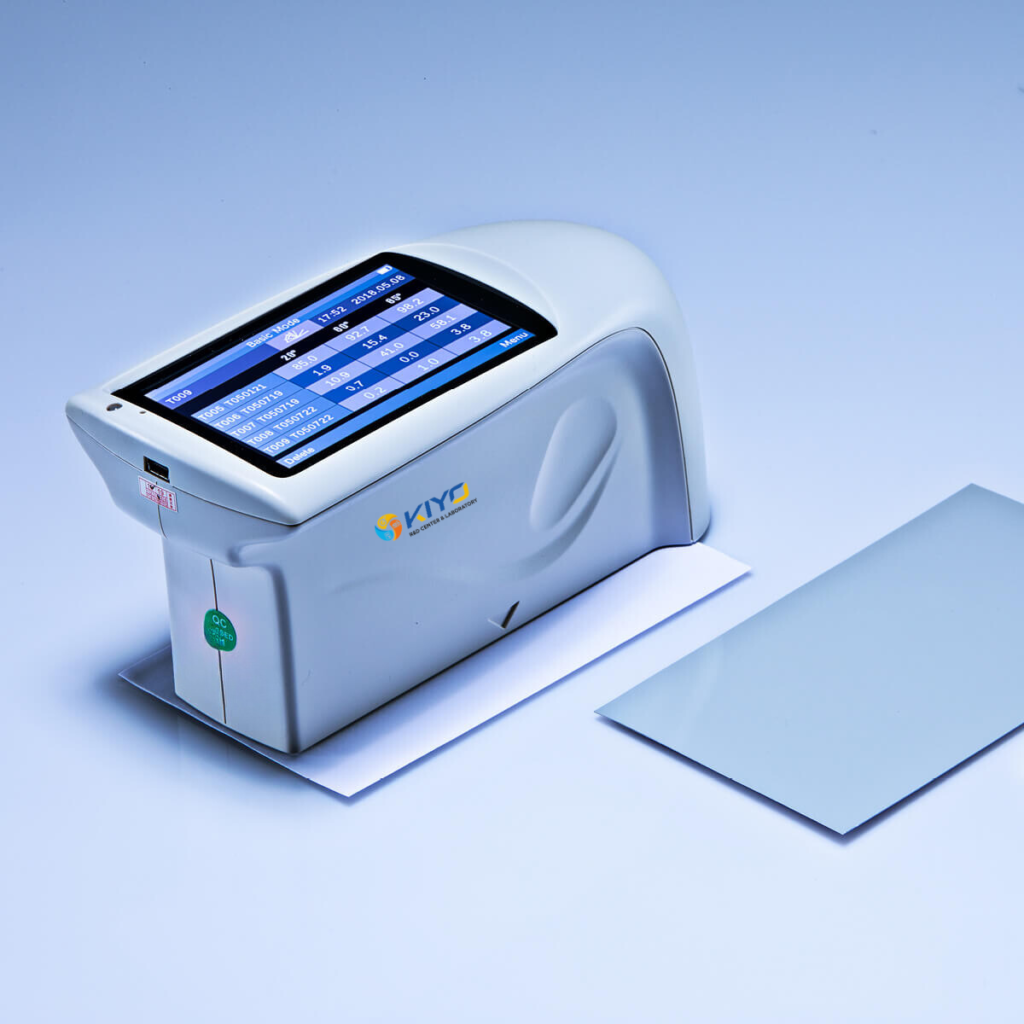

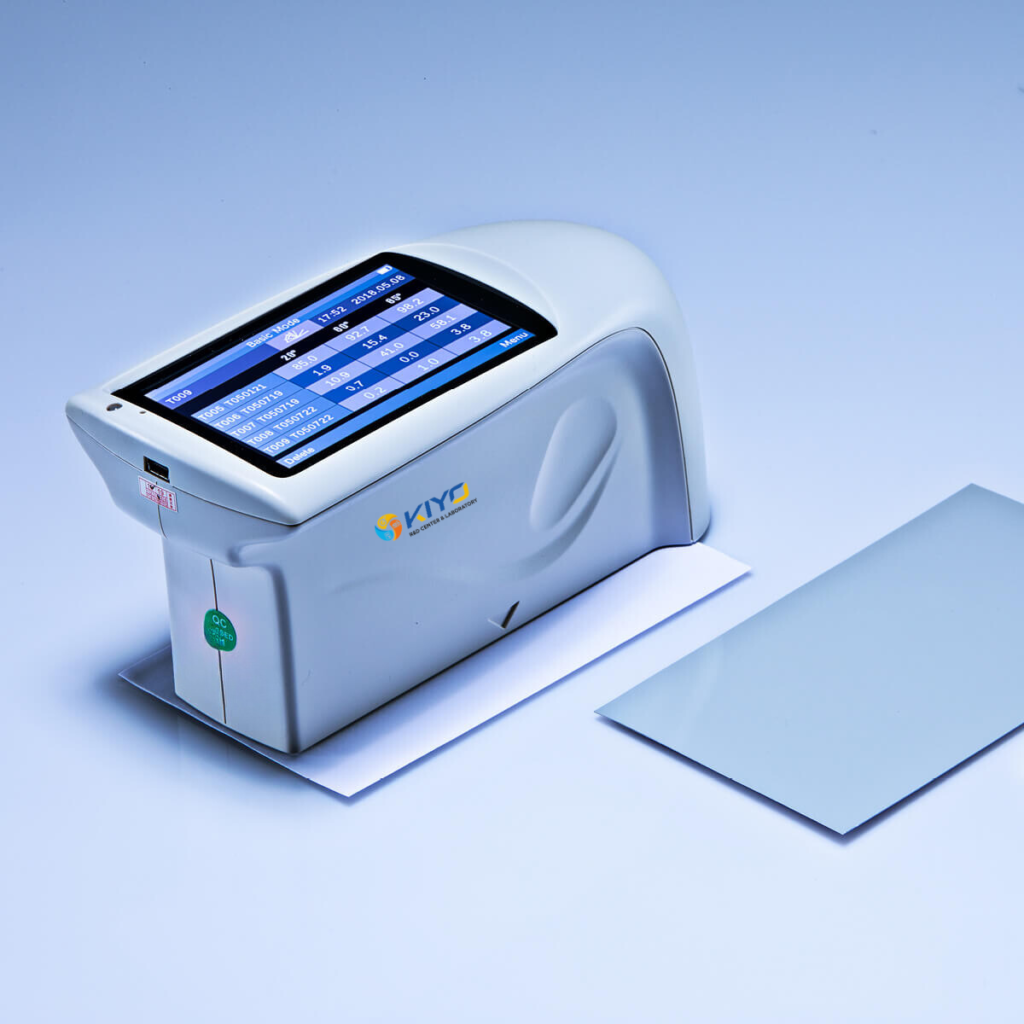

- Measurement Techniques: The standard employs a glossmeter, an instrument designed to measure the reflection of light from a surface. The glossmeter operates at specific angles—20°, 60°, and 85°—to accommodate different levels of gloss:

- 20°: Suitable for high-gloss surfaces.

- 60°: The general-purpose angle, used for a broad range of gloss levels.

- 85°: Best for low-gloss surfaces.

- Sample Preparation: Proper sample preparation is critical. Surfaces must be clean, free of scratches, and dry to ensure accurate readings. The standard outlines meticulous procedures for preparing samples to eliminate any variables that could affect the measurement.

- Calibration and Maintenance: Regular calibration of glossmeters using standard reference materials is mandated by MS 300-55. This ensures the accuracy and reliability of measurements, with specific guidelines provided for calibration procedures.

- Measurement Protocol: Detailed instructions are provided for conducting measurements. This includes the positioning of the glossmeter, the number of readings required, and the method for calculating the average gloss value. The standard advocates for multiple readings to account for surface inconsistencies.

- Reporting Standards: Transparency in reporting is emphasized. Results should include the measurement angle, average gloss value, and any deviations or anomalies. This detailed reporting aids in quality control and product comparison.

Applications in Industry

- Automotive: In the automotive sector, gloss is crucial for the exterior and interior finishes of vehicles. High gloss levels are often associated with premium quality, enhancing the vehicle’s aesthetic appeal.

- Consumer Electronics: Gloss impacts the visual and tactile experience of electronic devices. High gloss surfaces are common in smartphones and tablets, where appearance plays a significant role in consumer preference.

- Home Appliances: From refrigerators to washing machines, the gloss of the surface can influence the perceived cleanliness and modernity of the product.

Benefits of Adhering to MS 300-55

By following Standard MS 300-55, manufacturers can achieve several benefits:

- Consistency: Uniform gloss measurements across batches ensure product consistency.

- Quality Assurance: Accurate gloss measurement aids in maintaining high quality, meeting industry standards, and customer expectations.

- Reproducibility: The standard ensures that gloss measurements are reproducible, providing reliable data for quality control.

Conclusion

- Gloss is a fundamental property that affects the marketability and functionality of products. Standard MS 300-55 offers a robust framework for gloss measurement, ensuring precision and uniformity. By adhering to this standard, industries can enhance product quality, meet stringent market demands, and maintain a competitive edge.

FAQ

1. How often should glossmeters be calibrated?

Glossmeters should be calibrated regularly using standard reference materials with known gloss values. The frequency of calibration depends on the usage and manufacturer recommendations.

2. What information should be included in gloss measurement reports?

Reports should include the measurement angle, average gloss value, any deviations observed, and details about the sample preparation and measurement conditions.

3. In which industries is gloss measurement particularly crucial?

Gloss measurement is vital in the automotive, plastics, and consumer goods industries. It ensures the quality and visual appeal of products such as vehicle finishes, plastic components, and electronic devices.