Erichsen Scratch Test as Per MS 210-05

Ensuring Material Durability with the Scratch Test as Per MS 210-05: Hyundai's High Standard

Introduction

- In the field of materials testing, the Scratch Test is a crucial method for evaluating the scratch resistance of coatings and materials. This test is essential in determining whether materials can endure the daily wear and tear while maintaining their aesthetic and functional properties. One notable standard for this test is MS 210-05, a specification established by Hyundai, which emphasizes the importance of scratch resistance in automotive materials.

Overview of the Scratch Test

The Scratch Test assesses the scratch resistance of various coatings and surfaces. The test involves a controlled process where a diamond-tipped tool is dragged across the material’s surface under a specified load. The resulting scratch is then examined for its depth, width, and overall appearance, providing critical insights into the material’s durability and suitability for different applications.

Importance of MS 210-05

MS 210-05 is a Hyundai standard that sets rigorous requirements for the scratch resistance of materials used in automotive applications. This standard ensures that materials can withstand everyday use and maintain their quality and performance over time. Adherence to MS 210-05 means that materials have been tested to meet Hyundai’s high-quality standards.

Detailed Testing Procedure

The testing procedure involves several essential steps:

- Sample Preparation: Samples are prepared according to specific dimensions and surface conditions to ensure consistency and accuracy during testing.

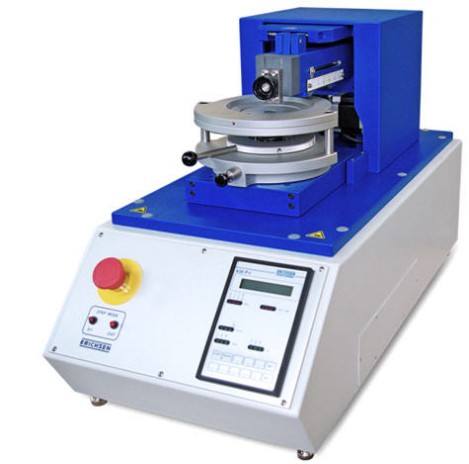

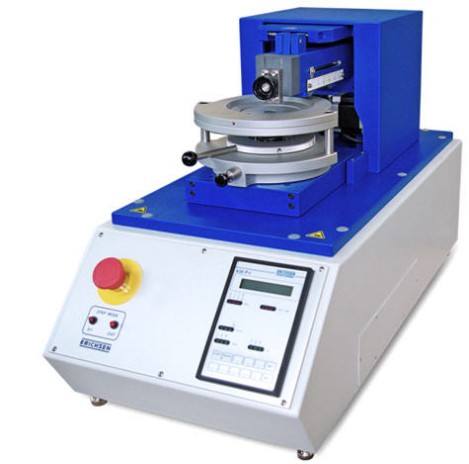

- Test Execution: Using a precision scratch tester, the sample undergoes a controlled scratch under the required load. The diamond tip is meticulously maintained to guarantee uniformity.

- Evaluation and Analysis: After scratching, the sample is analyzed using advanced microscopy techniques to measure the scratch’s dimensions and assess the material’s performance.

- Reporting: Comprehensive reports are generated, documenting the test conditions, results, and compliance with MS 210-05. These reports offer valuable insights for material selection and quality assurance.

Advantages of the Scratch Test

- Quality Assurance: Ensures that materials meet high standards of durability and performance.

- Informed Material Selection: Helps manufacturers select the best materials for their applications, reducing the risk of premature wear and tear.

- Compliance: Meeting Hyundai’s MS 210-05 standard demonstrates a commitment to quality and reliability, which is vital in the competitive automotive industry.

Why Choose Kiyo R&D Center & Laboratory?

At our laboratory, we excel in materials testing and are dedicated to upholding industry standards like MS 210-05. Our state-of-the-art facilities and experienced team ensure that every test is conducted with precision and accuracy, providing you with reliable and actionable results.

Conclusion

- The Scratch Test is essential for ensuring that materials can withstand real-world challenges, and adhering to standards like MS 210-05 is crucial for maintaining quality and performance. By choosing our laboratory, you partner with a leader in materials testing committed to excellence and innovation.