Durability Testing in Chennai

Comprehensive Durability Testing in Chennai: A Gateway to Material Excellence

Introduction

- Durability trying out plays a pivotal position in figuring out the reliability and lifespan of substances used across industries. In Chennai, a thriving industrial hub, the demand for superior durability checking out has soared, catering to sectors like automobile, construction, patron goods, and electronics. Let’s delve into the significance of durability checking out, its methodologies, and why Chennai stands out as a destination for modern-day cloth checking out services.

What is Durability Testing?

Durability testing evaluates a fabric’s potential to undergo environmental and mechanical stresses over the years. It replicates actual-international conditions to ensure that substances can resist their intended use with out compromising safety, performance, or exceptional.

Materials normally subjected to durability testing consist of:

- Plastics

- Rubbers

- Metals

- Composites

With stringent policies and customer expectancies, producers are adopting durability testing to beautify product reliability and construct customer trust.

Why is Durability Testing Essential?

Durability trying out is important for industries that rely on material integrity and overall performance under varying conditions. Key advantages consist of:

- Enhanced Product Longevity: Identifying cloth weaknesses before manufacturing minimizes the chance of untimely failure.

- Regulatory Compliance: Meeting global quality requirements guarantees worldwide market access.

- Cost Savings: Reducing material screw ups lowers guarantee claims and don’t forget charges.

- Customer Satisfaction: Durable merchandise beautify logo popularity and purchaser loyalty.

Chennai’s industries, from car giants to packaging innovators, depend upon rigorous durability trying out to preserve their competitive aspect.

Chennai: A Hub for Durability and Plastic Testing

Chennai’s industrial surroundings is powered via a strong network of testing laboratories and superior research centers. For producers looking for a plastic testing lab in Chennai, the city gives a number of contemporary centers to make certain substances meet industry requirements.

These labs cater to the metropolis’s booming car, electronics, and creation sectors through imparting complete testing services. Whether it’s trying out plastics for patron goods or assessing metals for structural sturdiness, Chennai’s understanding guarantees manufacturers stay ahead of global tendencies.

Key Durability Testing Methods

Testing methodologies vary based totally at the cloth and its software. Common techniques encompass:

- Mechanical Stress Testing: Evaluates a material’s performance under pressure, which includes tension, compression, and bending.

- Environmental Testing: Simulates harsh conditions which include UV publicity, temperature fluctuations, and humidity.

- Chemical Resistance Testing: Assesses how substances respond to exposure to chemicals, oils, and solvents.

- Thermal Testing: Measures material conduct below severe temperatures the usage of methods like HDT/VSP and DSC.

- Impact Testing: Tests fabric resistance to unexpected forces, important for plastics and metals.

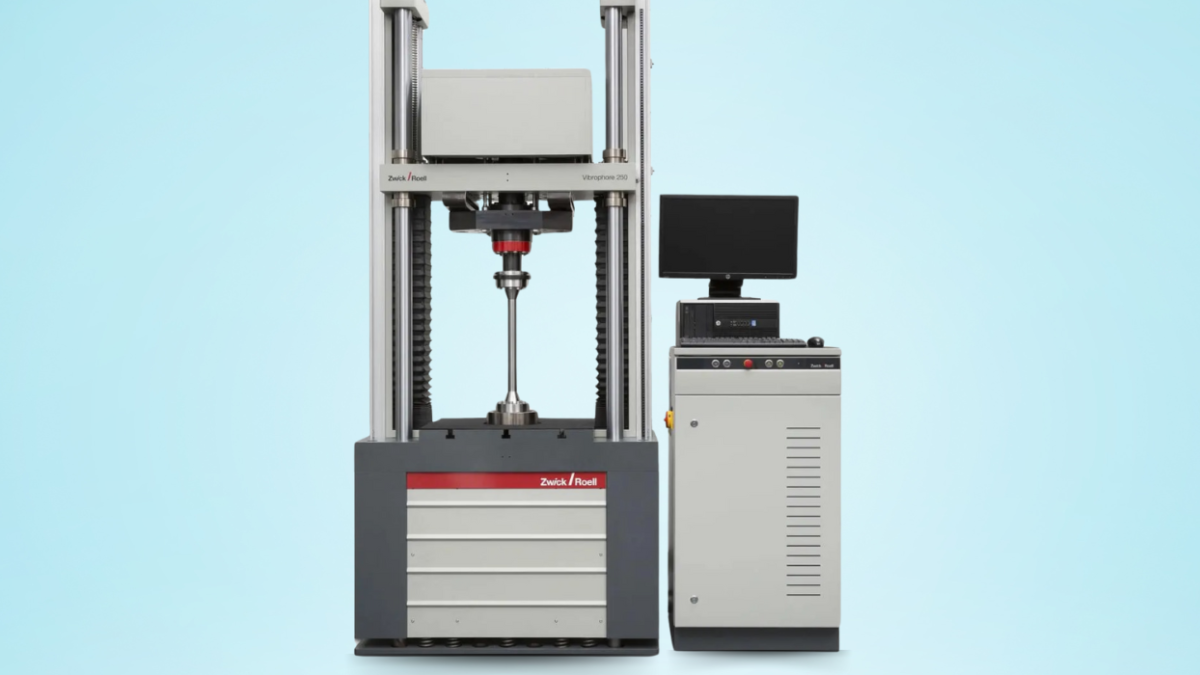

Advanced plastic checking out labs in Chennai are ready with present day technology to perform these assessments, making sure precise and reliable outcomes.

Applications of Durability Testing in Chennai’s Key Industries

Durability checking out plays a important role in Chennai’s industrial landscape. Here’s how it blessings key sectors:

- Automotive: Ensures automobile additives can resist vibrations, heat, and extended use.

- Construction: Verifies the integrity of materials like polymers, metals, and composites used in buildings and infrastructure.

- Electronics: Confirms the durability of plastic additives in consumer and industrial electronics.

- Consumer Goods: Tests plastics and rubbers for resistance to put on and tear in every day use.

The insights gained from durability checking out allow manufacturers to create sturdy, lengthy-lasting products, assembly the needs of each nearby and global markets.

Choosing a Reliable Plastic Testing Lab in Chennai

Selecting the right lab is vital for accurate durability checking out. Look for the following:

- Comprehensive Services: Labs providing a complete range of tests, along with tensile, flexural, thermal, and vibration checking out.

- Accreditation: Recognized certifications make sure adherence to worldwide trying out standards.

- Expert Team: Skilled technicians and analysts who can interpret outcomes effectively.

- Advanced Equipment: Cutting-area generation for unique measurements and simulations.

Chennai is domestic to some of the excellent plastic checking out labs, imparting quit-to-end material trying out solutions.

Durability Testing for Sustainable Manufacturing

Sustainability is an vital element of modern-day manufacturing. By ensuring materials are durable and reliable, producers can reduce waste and promote eco-friendly practices. Durability trying out permits the use of recyclable and biodegradable substances with out compromising performance.

Chennai’s fabric trying out labs play a big function in supporting industries transition to sustainable solutions, aligning with international environmental goals.

Final Thoughts

- As industries keep growing, the need for dependable sturdiness checking out in Chennai becomes increasingly vital. Advanced checking out not only ensures product fine but also allows producers gain regulatory compliance and hold purchaser believe. For the ones looking for a trusted plastic trying out lab in Chennai, the city’s well-equipped laboratories provide world-class offerings tailor-made to enterprise requirements.