Compressive Property Testing As Per Standard ASTM D790

Understanding Compressive Property Testing as per ASTM D790

Introduction

- In materials testing, understanding a material's behavior under different loads and conditions is critical for ensuring product safety, performance, and reliability. One such important test is the compressive property test, which evaluates how materials react under compression. This blog will explore the significance of compressive property testing according to ASTM D790 standards and its application across industries.

What is ASTM D790?

ASTM D790 is a standard test method widely used to determine the flexural properties of plastics and other polymer materials. Although it is primarily associated with flexural testing, ASTM D790 also provides essential guidelines for assessing the compressive properties of materials, particularly those that need to withstand significant compressive forces during their service life.

Why Compressive Property Testing Matters

Compressive property testing is essential for several reasons:

- Safety and Reliability: Materials used in structural applications must be able to withstand compressive forces without failure. Testing ensures that materials meet the necessary safety standards.

- Material Performance: Understanding how materials behave under compression helps engineers design products that perform as expected under load, avoiding unexpected deformations or failures.

- Product Development: It enables manufacturers to develop new materials with enhanced compressive properties suitable for specific applications, contributing to innovation.

The ASTM D790 Testing Procedure

The compressive property test according to ASTM D790 involves the following steps:

- Sample Preparation: The specimens are carefully prepared to ensure uniformity. Standard dimensions are required to achieve comparable and consistent results. Typically, rectangular specimens are used.

- Conditioning: Specimens are conditioned at a specified temperature and humidity level to ensure that environmental factors do not influence the test results. This conditioning period aligns the material’s behavior with real-world conditions.

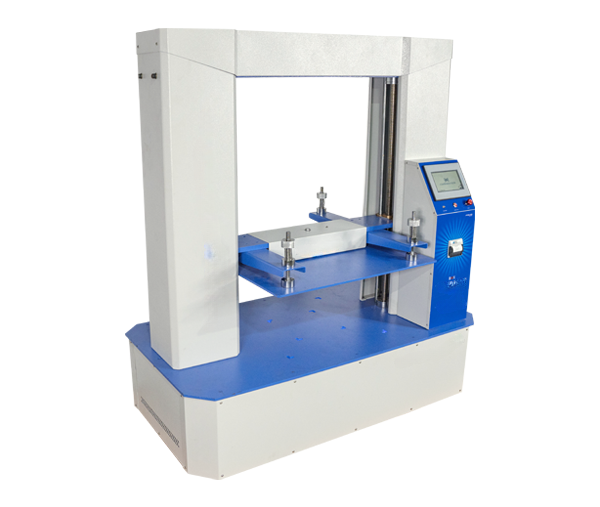

- Testing Setup: The specimen is placed in a testing machine where a compressive force is applied at a constant rate. The setup ensures that the force is applied uniformly across the specimen to avoid any bending or shear forces.

- Data Collection: As the compressive load is applied, data on the force and the corresponding deformation are recorded. The machine captures key parameters such as compressive strength, modulus, and strain.

Key Parameters Measured

- Compressive Strength: This is the maximum compressive load the material can bear before it begins to fail or fracture. It provides insight into the material’s load-bearing capacity.

- Compressive Modulus: It measures the stiffness of the material under compressive loads. A higher modulus indicates that the material is less likely to deform under compression.

- Strain at Break: The amount of deformation experienced by the material at the point of failure. It indicates how much a material can compress before it ultimately breaks.

Applications of ASTM D790 Compressive Testing

ASTM D790 compressive property testing is vital across various industries:

- Construction: Materials like concrete, plastics, and composites are tested to ensure they can handle the compressive forces encountered in buildings and infrastructure.

- Automotive and Aerospace: Components such as panels and structural parts are tested to ensure they can withstand compressive forces during use, ensuring safety and performance.

- Packaging: Testing ensures that packaging materials can withstand the compressive forces they might experience during stacking and transportation.

- Consumer Goods: Household items and appliances made from plastic and composite materials are tested to ensure durability and safety under compressive loads.

Conclusion

- Compressive property testing under ASTM D790 is a crucial aspect of materials testing that ensures materials can withstand compressive loads without failure. By adhering to these standards, manufacturers and engineers can guarantee the safety, reliability, and performance of their products. Understanding and applying the results of these tests is fundamental to advancing material science and engineering design.

FAQ

1. What are the key parameters measured during compressive property testing?

Key parameters include compressive strength (the maximum stress the material can handle before failing), compressive modulus (the stiffness of the material under compression), and strain at break (the amount of deformation before the material breaks).

2. What industries benefit from compressive property testing as per ASTM D790?

Industries such as aerospace, automotive, construction, packaging, and medical devices benefit from ASTM D790 testing to ensure materials can withstand compressive forces and maintain performance and safety.

3. How does ASTM D790 testing help in product development?

By providing detailed data on how materials behave under compressive loads, ASTM D790 testing helps engineers and designers select the right materials, optimize product designs, and develop new materials with enhanced properties.

4. Is conditioning of specimens necessary for ASTM D790 testing?

Yes, conditioning is necessary to ensure that test results are consistent and reflect the material's behavior under expected environmental conditions. This typically involves maintaining the specimens at a specific temperature and humidity level before testing.

5. Can ASTM D790 be used for testing materials other than plastics?

While ASTM D790 is primarily designed for plastics, it can also be adapted for other materials, especially composite materials used in structural applications that need to be assessed for their compressive properties.

6 What is the significance of the compressive modulus in ASTM D790 testing?

The compressive modulus indicates how stiff a material is under compression. A higher compressive modulus means the material will resist deformation, which is important for applications requiring strong, rigid materials.