Color Measurement Testing As per standard ASTM E1347

Color Measurement Testing as per ASTM E1347: Ensuring Precision in Color Consistency

Introduction

- In the world of manufacturing, especially in industries like plastics, textiles, coatings, and automotive, maintaining consistent color across products is critical. A slight variation in color can significantly affect product quality and customer satisfaction. That’s where standardized color measurement testing comes into play. ASTM E1347 is one of the most recognized standards for conducting precise color measurements. This blog explores how ASTM E1347 sets the benchmark for color testing, ensuring products meet their exact color requirements.

What is ASTM E1347?

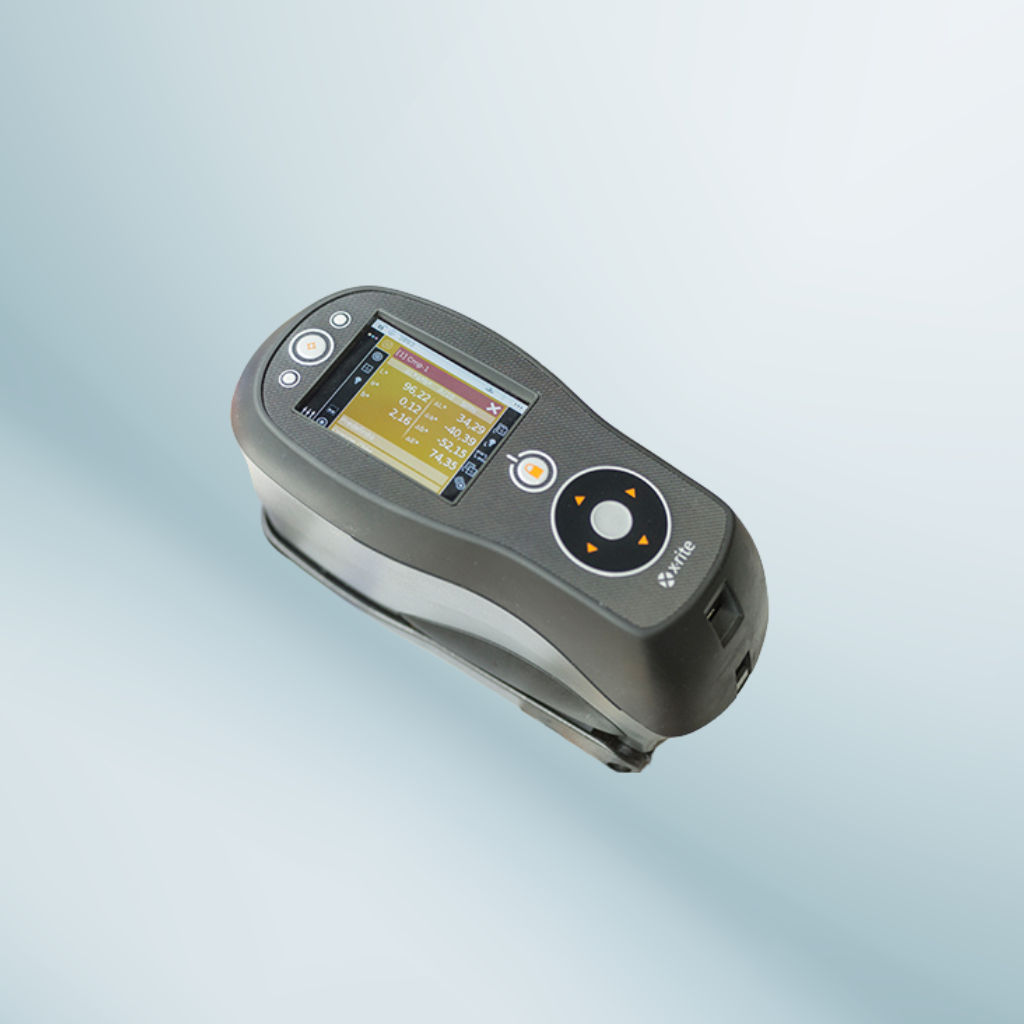

ASTM E1347, known as the “Standard Test Method for Color and Color-Difference Measurement by Tristimulus (Filter) Colorimetry,” provides guidelines for measuring the color of materials using tristimulus colorimeters. These devices simulate how the human eye perceives color by filtering light into red, green, and blue wavelengths. ASTM E1347 is vital in quality control, research, and product development to ensure that the color of materials meets specific standards and customer expectations.

Why Color Measurement Matters

Color is a powerful aspect of product identity. In the plastics industry, for example, ensuring that a product maintains its color consistency across different batches is essential for brand recognition and customer trust. In textiles, maintaining precise colors can be the difference between a successful product launch and returns due to customer dissatisfaction.

By using ASTM E1347, industries can maintain stringent control over color differences, ensuring that each product reflects the desired shade and quality. This standard serves as a reliable method for assessing color in an objective, repeatable manner.

Key Aspects of ASTM E1347

- Tristimulus Colorimetry: ASTM E1347 specifies the use of tristimulus colorimeters. These instruments use filters that correspond to the human eye’s sensitivity to light, providing a numerical representation of color in terms of the CIE XYZ or CIE LAB color spaces. This approach ensures that color measurements are standardized and can be consistently interpreted.

- Controlled Lighting Conditions: The standard emphasizes the importance of standardized lighting conditions during color measurement. It often requires using specific illuminants, such as D65 (representing daylight), to simulate natural lighting conditions and provide consistent color readings. This helps avoid discrepancies caused by different ambient lighting environments.

- Sample Preparation: Preparing the sample correctly is crucial to obtaining accurate measurements. ASTM E1347 outlines that the sample’s surface should be clean, smooth, and free of contaminants, such as dust, oils, or residues, that can affect the reflectance of light and, consequently, the color reading. Uniformity in sample thickness and texture is also emphasized to ensure repeatable results.

- Measurement Procedure: The procedure involves placing the sample in the instrument’s measurement area. The colorimeter measures the reflected or transmitted light through specific filters that mimic the RGB channels of human vision. The data is then processed to yield color coordinates, allowing the precise comparison of the sample’s color to a reference or standard.

- Interpreting Results: ASTM E1347 uses color coordinates to quantify differences in color, often using the ΔE (delta E) value to express the difference between the measured sample and the reference. The lower the ΔE value, the closer the sample’s color is to the target. This numerical approach helps manufacturers easily identify and correct color inconsistencies.

Applications of ASTM E1347

Plastics and Polymers: Plastic products need consistent colors for both functional and aesthetic purposes. ASTM E1347 allows manufacturers to ensure that products like automotive parts, consumer goods, and packaging materials meet specific color tolerances, reducing the likelihood of customer dissatisfaction.

Textiles and Fabrics: In the textile industry, maintaining exact colors throughout the production process is crucial. ASTM E1347 assists in color matching during dyeing and finishing processes, ensuring that the final product’s color matches design specifications.

Coatings and Paints: For paints and coatings, color consistency is critical to brand quality. ASTM E1347 enables manufacturers to measure and control the color of paints, coatings, and finishes, ensuring uniform appearance and meeting customer expectations.

Printing: In printing, ASTM E1347 is used to verify color accuracy in printed materials, ensuring that the final output aligns with the design specifications.

Benefits of Using ASTM E1347

- Improved Quality Control: By providing a standardized method for color measurement, ASTM E1347 allows manufacturers to monitor and control color variations during production, ensuring consistent product quality.

- Enhanced Product Consistency: Following ASTM E1347 ensures that products maintain their intended color, which is crucial for brand identity and customer satisfaction.

- Ease of Communication: The standard’s use of numerical color data facilitates clear communication about color requirements between different stakeholders, such as suppliers, manufacturers, and quality control teams.

- Inter-Laboratory Consistency: Because ASTM E1347 provides a universal method for color measurement, results can be compared reliably between different laboratories and production facilities, ensuring consistency across locations.

Tips for Effective Color Measurement

- Regular Calibration: To maintain accuracy, regularly calibrate the colorimeter using the manufacturer’s recommended procedures.

- Consistent Environment: Conduct measurements in a controlled environment to minimize the influence of external factors, such as ambient lighting and temperature.

- Proper Sample Handling: Handle samples carefully to avoid contamination or damage that could alter the color reading.

Conclusion

- ASTM E1347 is an essential standard for industries where color consistency is a key aspect of product quality. By providing detailed procedures for color measurement using tristimulus colorimetry, it helps manufacturers control product appearance, maintain brand standards, and meet customer expectations. With the application of ASTM E1347, companies can ensure that every product meets the specified color criteria, resulting in higher quality products and greater customer satisfaction.