The Cornerstone of Polymer Reliability: Why Testing Matters

Imagine a world where the plastic components in your car failed under stress, or the polymers in medical implants degraded prematurely. The consequences could be catastrophic. Polymer testing acts as the gatekeeper, verifying that these vital materials meet the stringent demands of their intended use. Its significance spans across various critical aspects:

- Safety Assurance: Identifying potential weaknesses and ensuring polymers comply with safety regulations, protecting end-users.

- Performance Validation: Confirming that materials possess the required mechanical, thermal, and chemical properties for optimal functionality and longevity.

- Quality Control: Maintaining consistency in polymer production, minimizing defects, and ensuring batch-to-batch uniformity.

- Research and Development Advancement: Providing crucial data and insights to facilitate the development of novel polymers and the enhancement of existing ones.

- Regulatory Compliance: Meeting mandatory national and international standards, enabling market access and building consumer confidence.

- Failure Analysis and Prevention: Investigating product failures to pinpoint root causes, implement corrective measures, and prevent future incidents.

Without access to sophisticated polymer test lab in Chennai facilities, industries would be navigating uncharted territories, risking product failures, financial losses, and, most importantly, compromising safety.

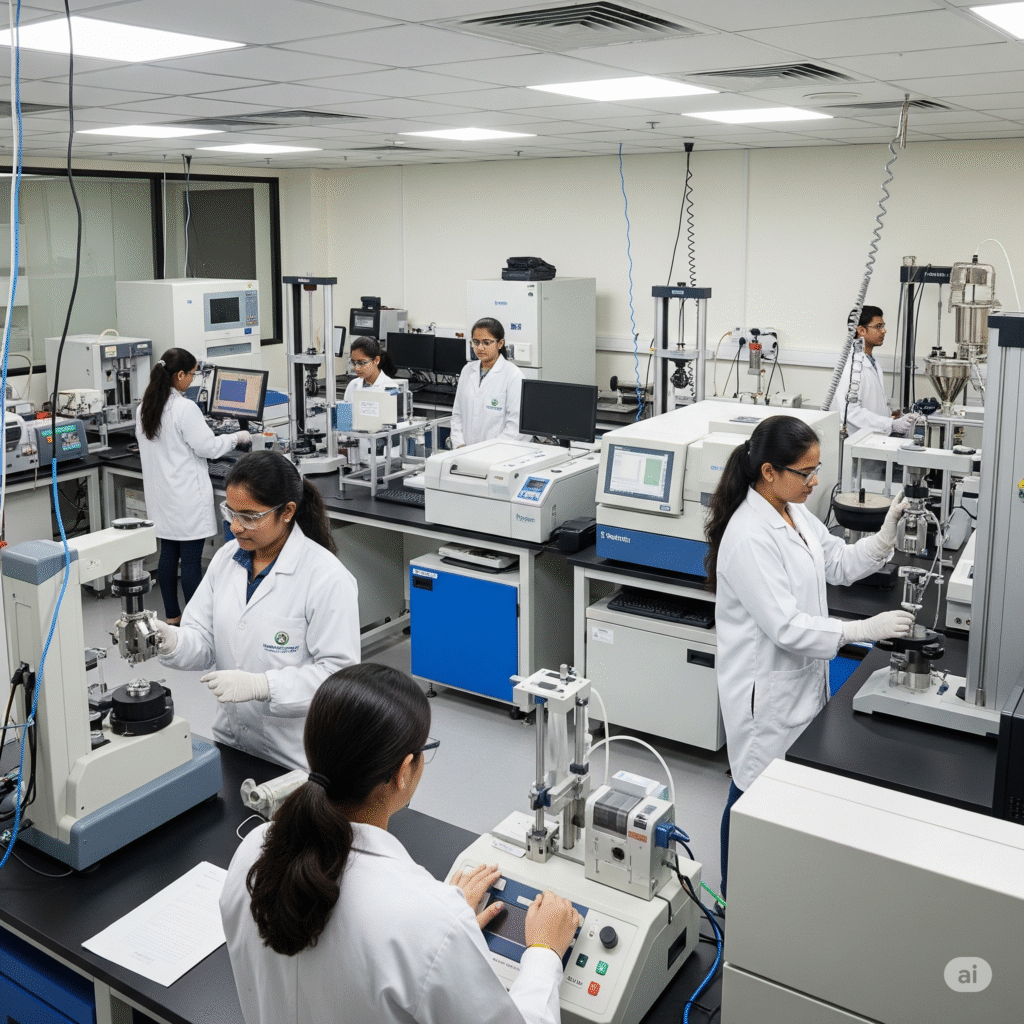

Kiyo R&D Center and Laboratory: Setting the Standard in Chennai’s Polymer Testing Landscape

Nestled in the industrial heart of Chennai, Kiyo R&D Center and Laboratory has established itself as a leading authority in advanced polymer testing. Their unwavering commitment to quality, cutting-edge technology, and a team of highly qualified experts make them the preferred partner for a diverse range of industries seeking reliable and accurate material evaluation.

A Deep Dive into Kiyo R&D’s Comprehensive Testing Portfolio

Kiyo R&D Center and Laboratory boasts an extensive array of polymer testing services, meticulously designed to address the diverse needs of their clientele. Their state-of-the-art laboratory is equipped with the latest instrumentation to conduct a wide spectrum of analyses:

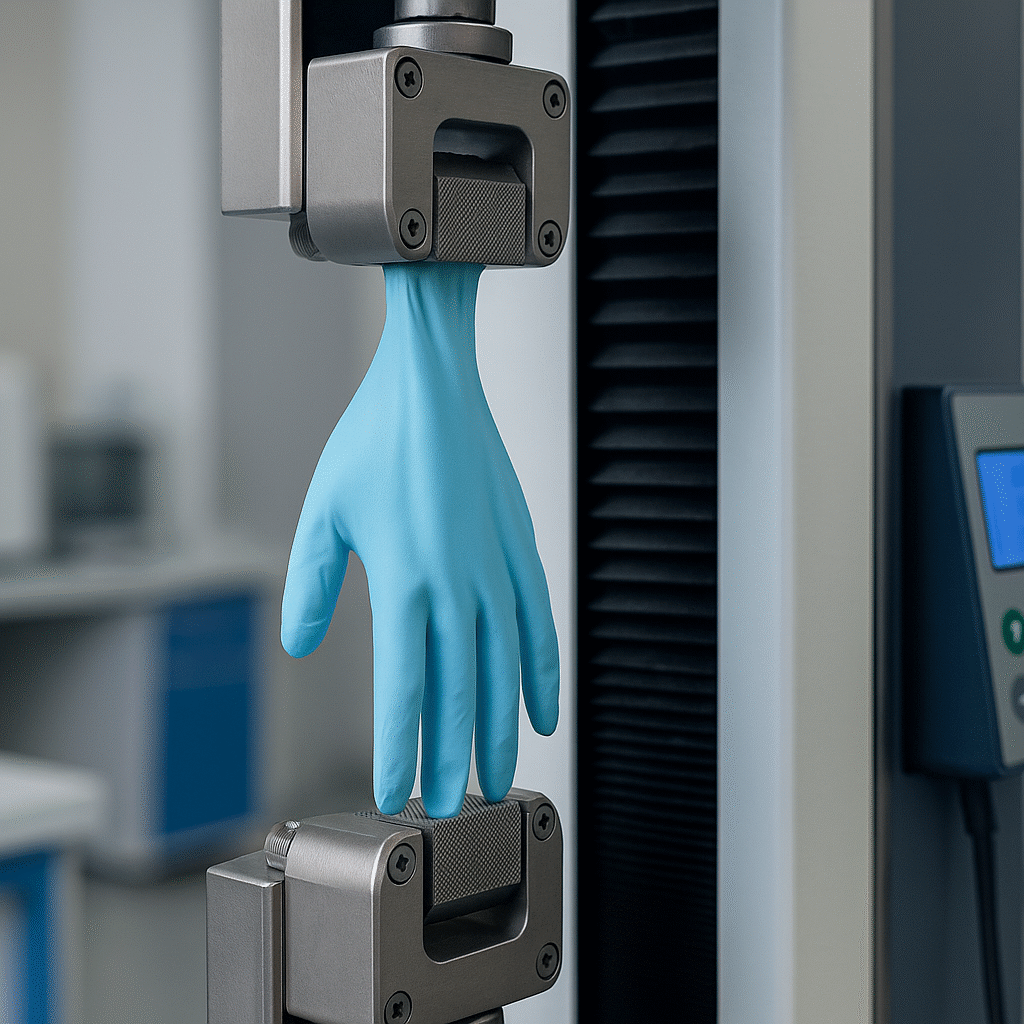

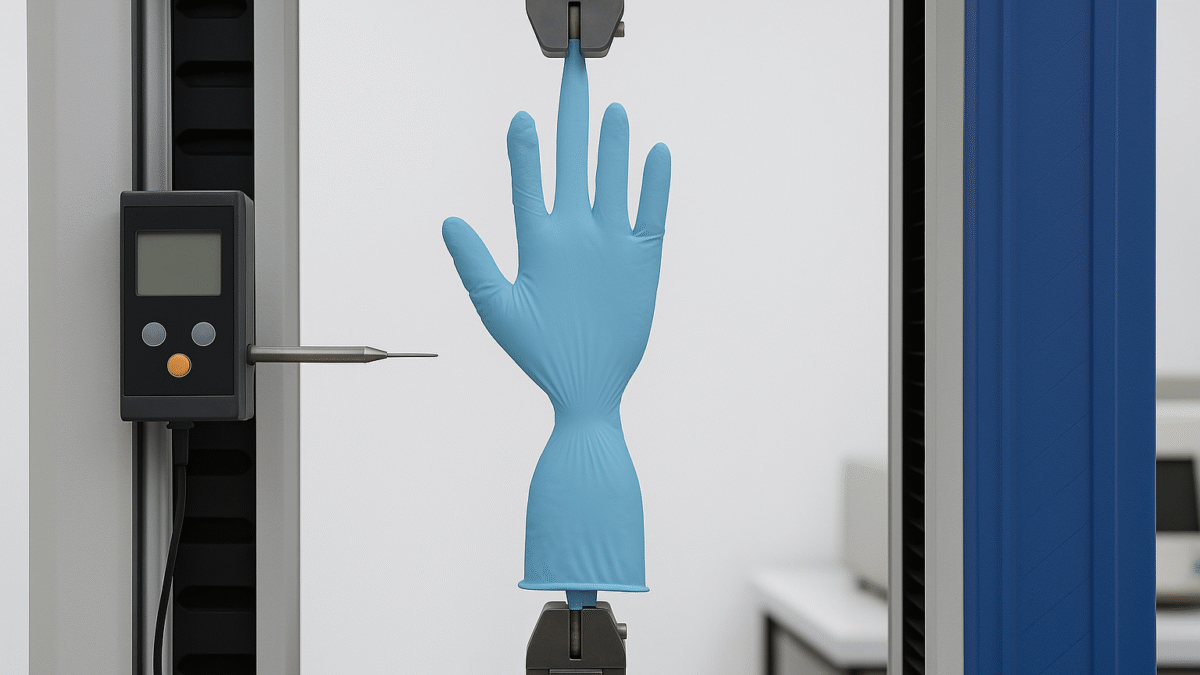

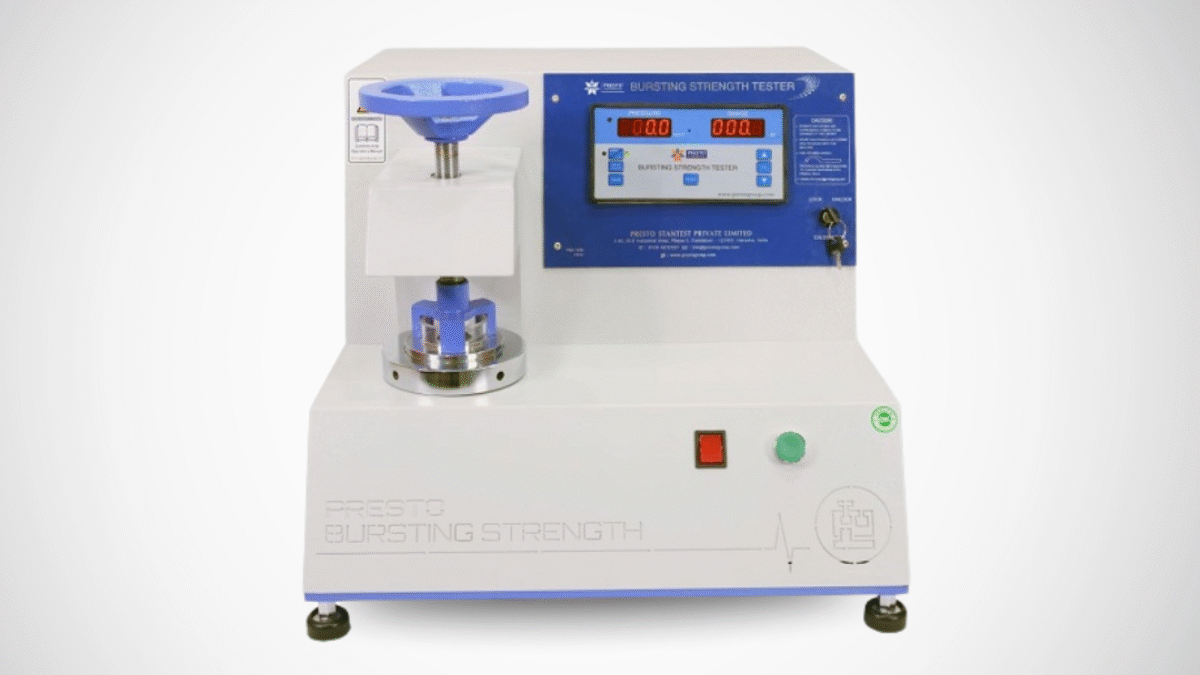

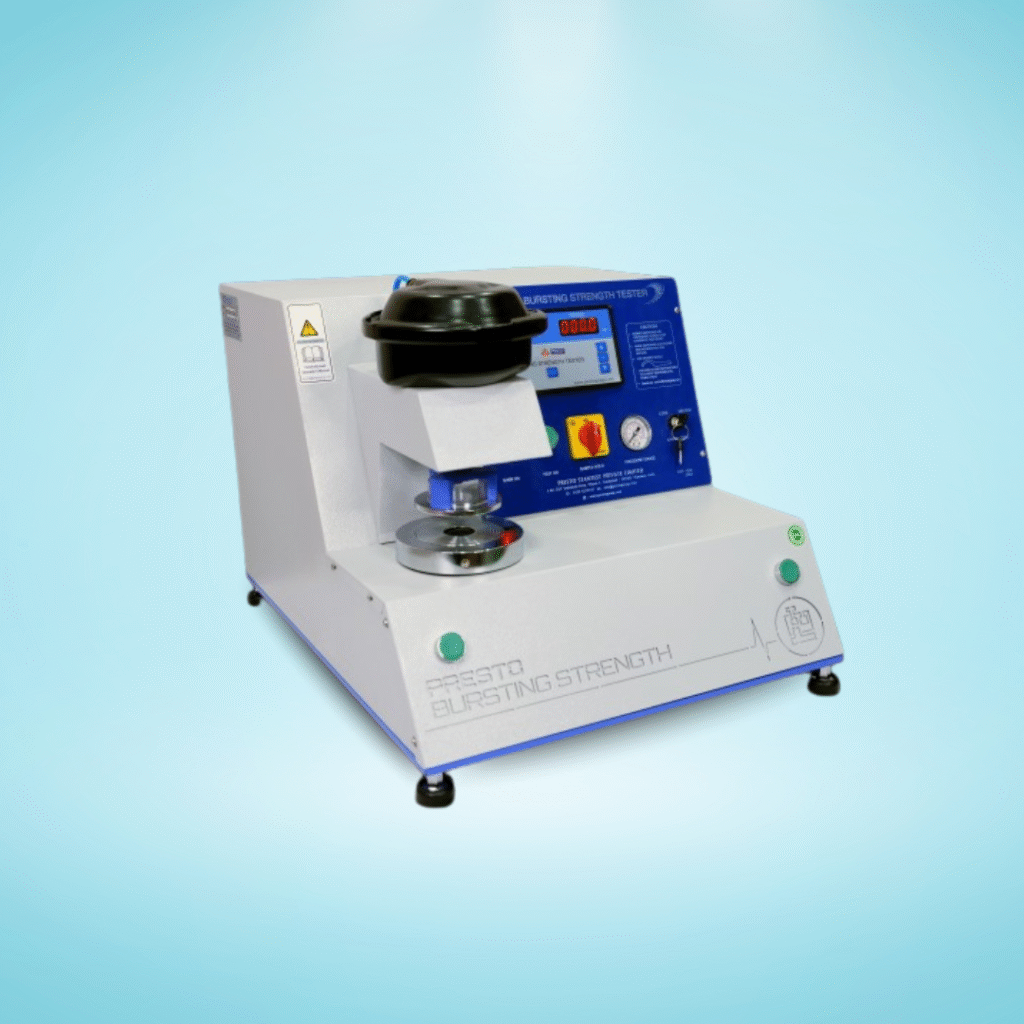

1. Delving into Strength and Resilience: Mechanical Testing

Understanding a polymer’s response to physical forces is paramount. Kiyo R&D offers a comprehensive suite of mechanical tests, including:

- Tensile Testing: Quantifying a material’s strength under stretching forces, its elongation capabilities, and its stiffness. Crucial for applications where the polymer will be subjected to pulling or tensile loads.

- Flexural Testing: Assessing a polymer’s resistance to bending, an essential parameter for components like pipes, beams, and flexible housings.

- Impact Testing (Izod & Charpy): Evaluating a material’s ability to withstand sudden shocks or impacts without fracturing, vital for safety-critical components.

- Hardness Testing (Durometer & Micro Hardness): Measuring a polymer’s resistance to indentation and scratching, indicative of its surface durability and wear resistance.

- Compression Testing: Determining a material’s behavior under crushing forces, important for load-bearing applications.

- Shear Testing: Assessing a polymer’s strength when subjected to forces acting parallel to its surface.

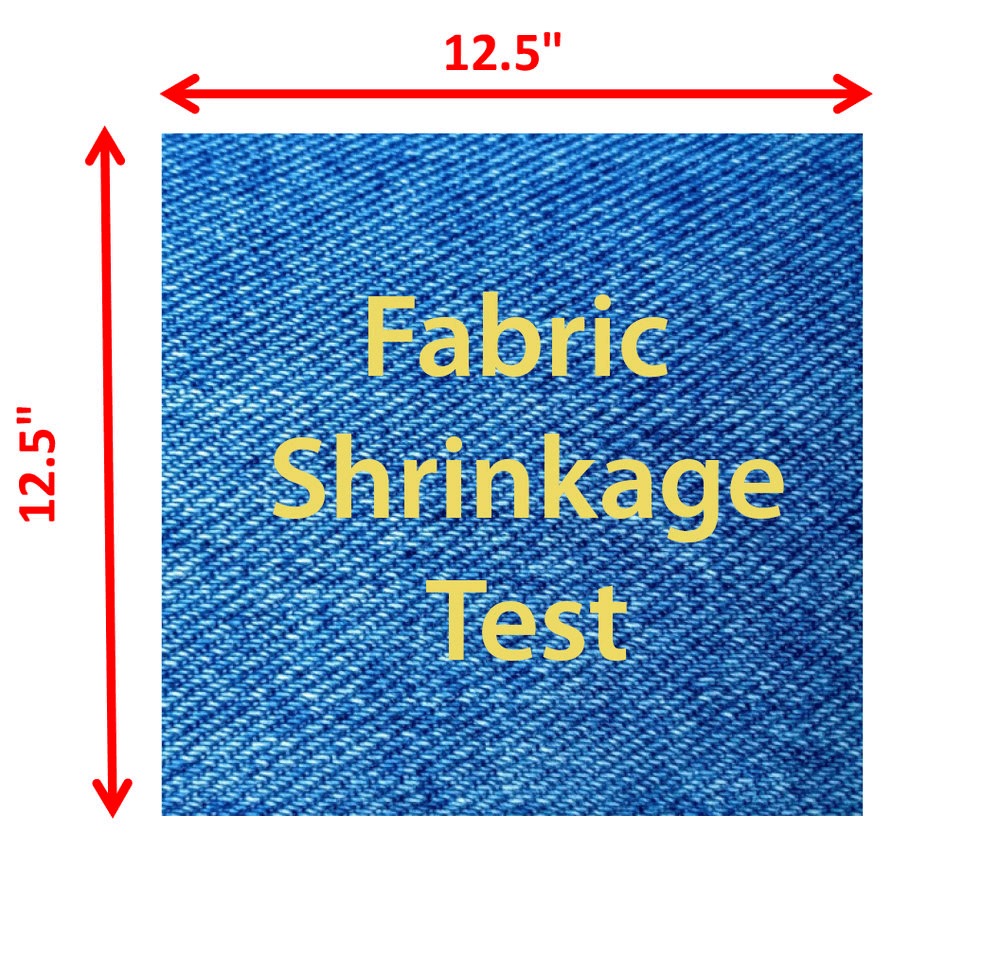

- Tear Resistance Testing: Evaluating a flexible material’s ability to resist tearing, crucial for films, sheets, and fabrics.

2. Unraveling Thermal Behavior: Thermal Analysis

Polymers exhibit unique responses to temperature changes, which significantly impact their processing and end-use performance. Kiyo R&D’s thermal analysis capabilities include:

- Melt Flow Index (MFI): Measuring the ease with which a molten thermoplastic polymer flows under specific conditions, critical for optimizing molding and extrusion processes.

- Differential Scanning Calorimetry (DSC): Analyzing the thermal transitions of a polymer (e.g., melting point, glass transition temperature, crystallization) to understand its processing characteristics and application temperature range.

- Thermogravimetric Analysis (TGA): Determining a polymer’s thermal stability and compositional breakdown by monitoring weight changes as a function of temperature.

- Dynamic Mechanical Analysis (DMA): Characterizing the viscoelastic properties of polymers as a function of temperature, frequency, and stress, providing insights into their stiffness, damping, and relaxation behavior.

- Heat Deflection Temperature (HDT) / Vicat Softening Point (VSP): Determining the temperature at which a polymer begins to deform under a specific load, indicating its high-temperature performance limitations.

3. Investigating Composition and Interactions: Chemical Analysis

Understanding the chemical makeup and reactivity of polymers is vital for quality control and problem-solving. Kiyo R&D offers a range of chemical analysis services:

- Fourier Transform Infrared Spectroscopy (FTIR): Identifying the chemical composition of polymers and detecting the presence of specific functional groups or contaminants.

- Elemental Analysis: Determining the elemental composition of a polymer material.

- Filler Content Analysis: Quantifying the amount of inorganic fillers present in a polymer composite, which significantly affects its mechanical properties.

- Chemical Resistance Testing: Evaluating a polymer’s ability to withstand exposure to various chemicals without degradation.

- Spectroscopy (UV-Vis, NMR): Providing further insights into the molecular structure and properties of polymers.

- Chromatography (GC-MS, HPLC): Separating and identifying the components of complex polymer mixtures.

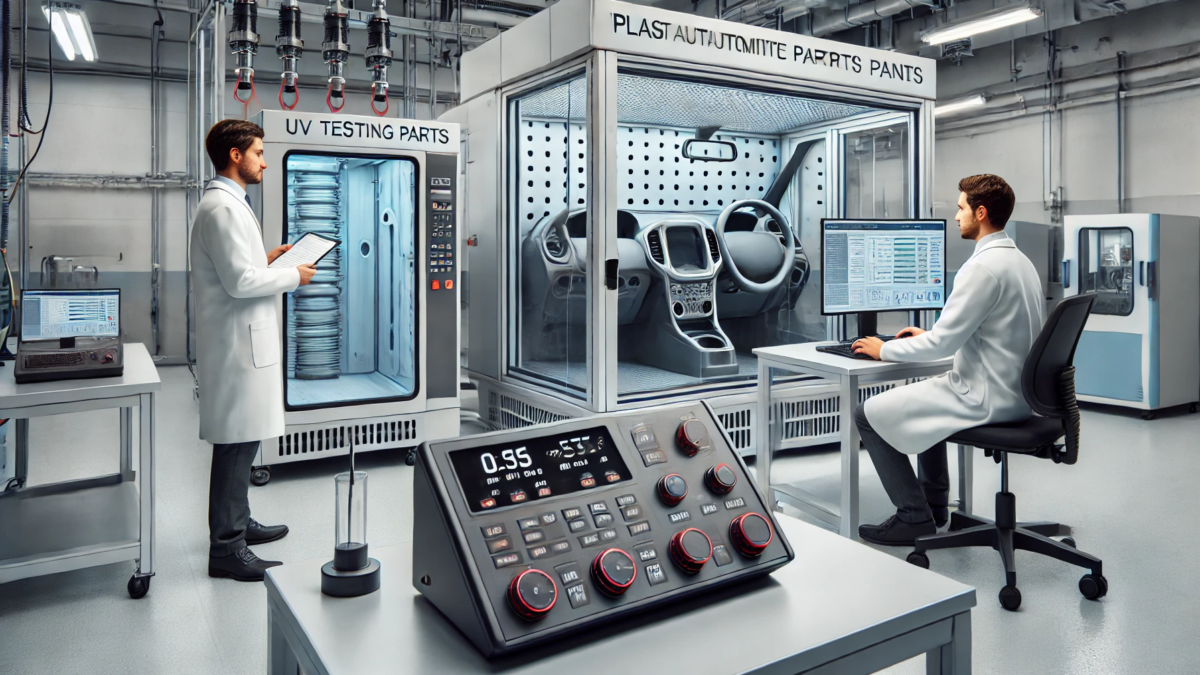

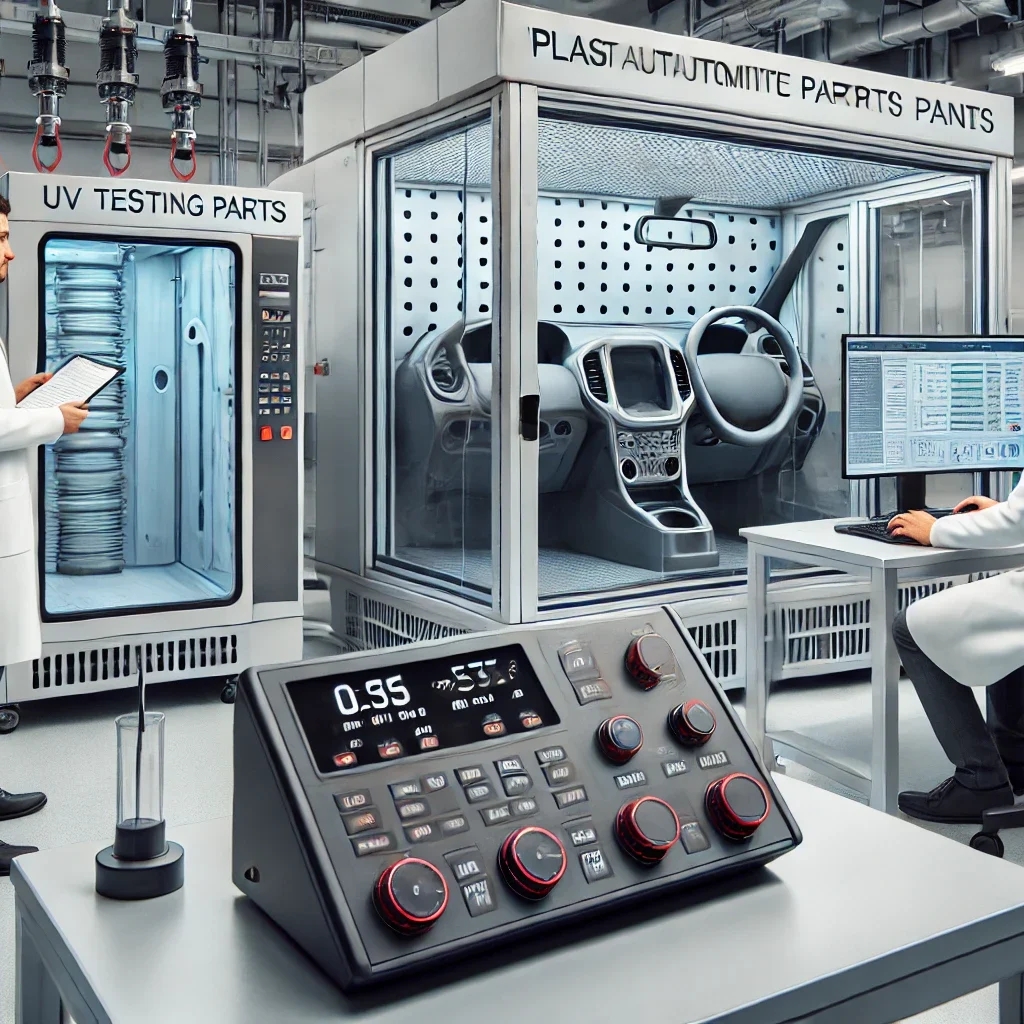

4. Tailored Solutions for Specific Needs: Specialized Testing

Recognizing the unique demands of various industries, Kiyo R&D also provides specialized testing services:

- Flammability Testing: Assessing a polymer’s resistance to ignition and its burning behavior, crucial for applications where fire safety is paramount.

- Accelerated Weathering and UV Degradation: Simulating long-term exposure to environmental factors like sunlight, temperature, and humidity to predict the long-term durability of polymers.

- Electrical Properties Testing: Evaluating a polymer’s dielectric strength, resistivity, and other electrical characteristics, essential for electrical and electronic applications.

- Ageing Tests: Assessing the long-term performance of polymers under specific temperature and humidity conditions.

- Migration Testing: Determining the extent to which substances can migrate from a polymer material into a surrounding medium, important for food packaging and medical devices.

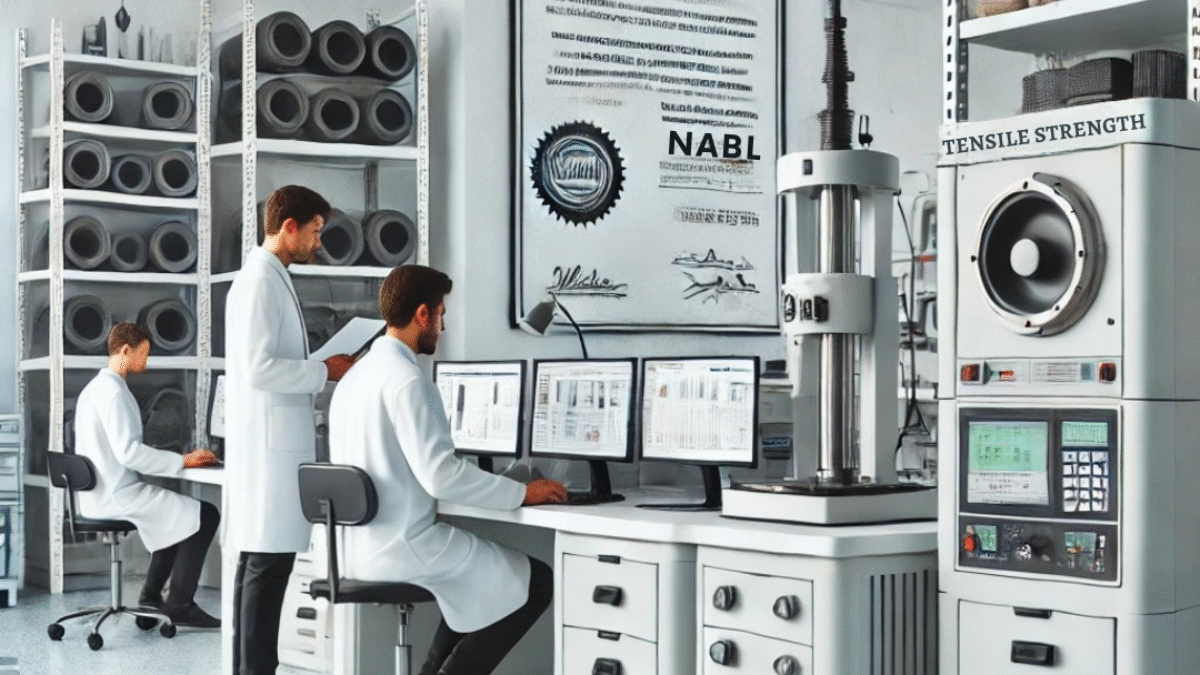

The Kiyo R&D Advantage: Why Partner with Them?

Choosing the right polymer test lab in Chennai is crucial. Kiyo R&D Center and Laboratory offers several compelling advantages:

- NABL Accreditation: Their accreditation to ISO/IEC 17025 standards guarantees the highest level of competence and reliability in their testing procedures.

- Expert Team: A dedicated team of experienced scientists, engineers, and technicians with in-depth knowledge of polymer science and testing methodologies.

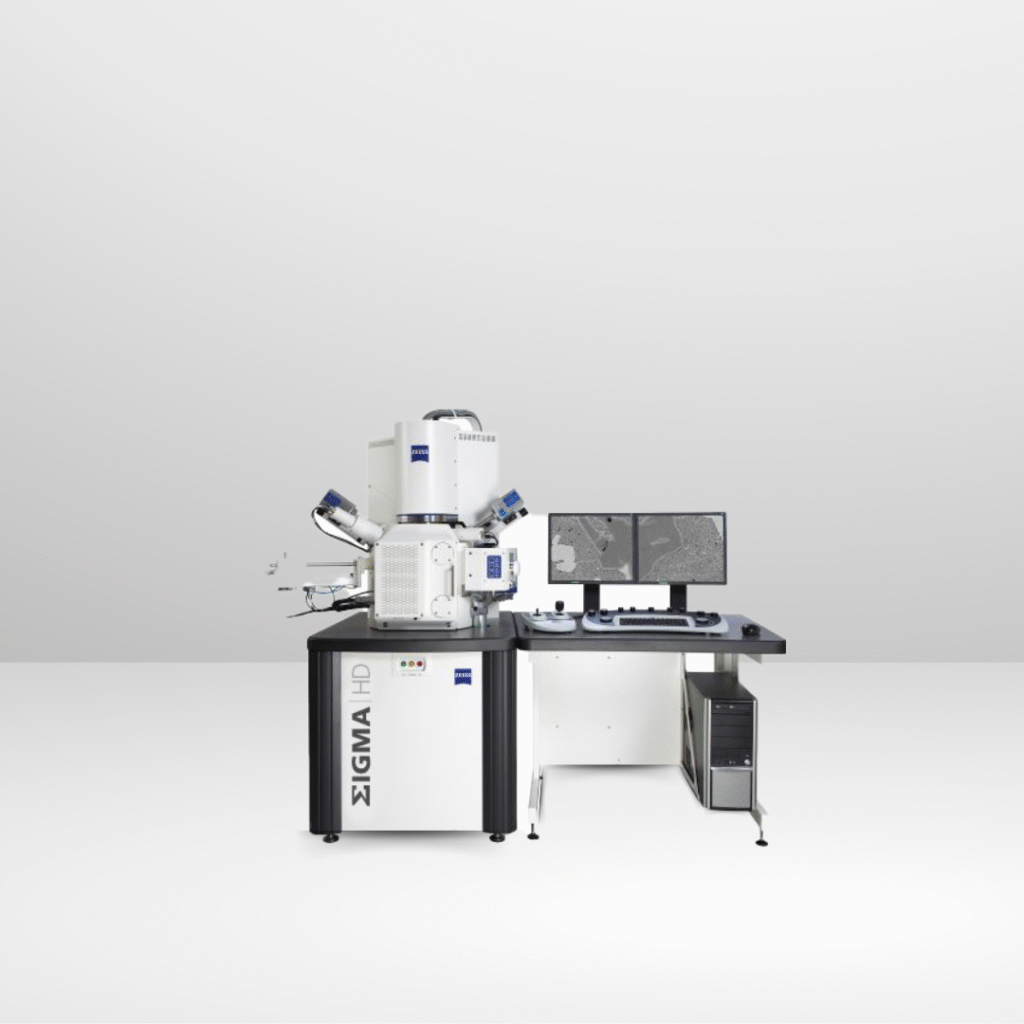

- Advanced Infrastructure: A well-equipped laboratory with cutting-edge instrumentation ensures accurate, precise, and repeatable results.

- Comprehensive Service Portfolio: A wide range of testing services under one roof simplifies the testing process for clients.

- Customer-Focused Approach: They prioritize client needs, offering customized testing solutions, timely results, and expert technical support.

- Commitment to Quality: Adherence to stringent quality control measures ensures the integrity and reliability of all test data.

- Strategic Location: Based in Chennai, a major industrial hub, providing easy access for businesses across South India.

Driving Innovation and Ensuring Excellence: The Role of Kiyo R&D

In conclusion, advanced polymer testing is an indispensable element in ensuring the reliability, safety, and innovation of polymer-based products. Kiyo R&D Center and Laboratory in Chennai stands at the forefront of this critical field, providing comprehensive, accurate, and accredited testing services to a diverse range of industries. By partnering with Kiyo R&D, businesses can unlock the full potential of their polymer materials, confidently navigate regulatory landscapes, and ultimately deliver high-quality products that meet the evolving demands of the market. For any organization seeking a trusted and expert polymer test lab in Chennai, Kiyo R&D Center and Laboratory is the clear choice for achieving material excellence.