Plastics are everywhere—automotive parts, packaging materials, electrical housings, consumer products, engineering components, and thousands of everyday applications. Yet behind every reliable plastic product lies a critical mechanical property that determines its real-world performance: tensile strength.

Whether a product will stretch, break, deform, or survive under load depends on how it behaves when pulled. That’s why tensile testing for plastics services in India @ Kiyo R&D LAB plays an essential role in quality assurance, product development, and material selection across industries.

In this blog, we explore how tensile testing works, why it matters, what industries rely on it, and how Kiyo R&D LAB delivers accurate, NABL-accredited testing services for both businesses and engineering students across India.

What Is Tensile Testing?

Tensile testing is a scientific method of stretching a plastic specimen until it breaks. During the test, we measure:

- How much force the material can handle

- How far it can stretch before breaking

- How stiff it is under load

- How it behaves under continuous stress

These properties help determine whether the plastic material is suitable for its intended application.

A typical tensile test provides several important values:

- Tensile Strength – Maximum stress before breaking

- Elongation at Break – How much it stretches before failure

- Young’s Modulus – Stiffness or resistance to deformation

- Yield Strength – Stress at which permanent deformation begins

These measurements create a complete mechanical profile of the plastic.

Why Tensile Testing Is Essential for Plastics

Manufacturers, OEMs, and designers rely on tensile testing for plastics services in India @ Kiyo R&D LAB because tensile strength determines:

1. Structural Performance

Will a component hold its shape?

Will it bend, warp, or deform under load?

2. Durability

Parts used in automotive or industrial applications must survive long-term stress.

3. Safety

Weak materials can crack unexpectedly, leading to product failure or hazards.

4. Material Comparison

Tensile results help in choosing the best polymer grade—HDPE vs PP vs ABS vs Nylon, etc.

5. Quality Control

Ensures consistent results between batches, suppliers, or production cycles.

6. Failure Analysis

When products fail, tensile testing helps diagnose the root cause.

7. Academic Research

Final-year engineering projects depend on accurate tensile values for analysis.

Without tensile testing, engineering decisions become assumptions—and that leads to poor product performance, customer complaints, and safety risks.

How Tensile Testing Works at Kiyo R&D LAB

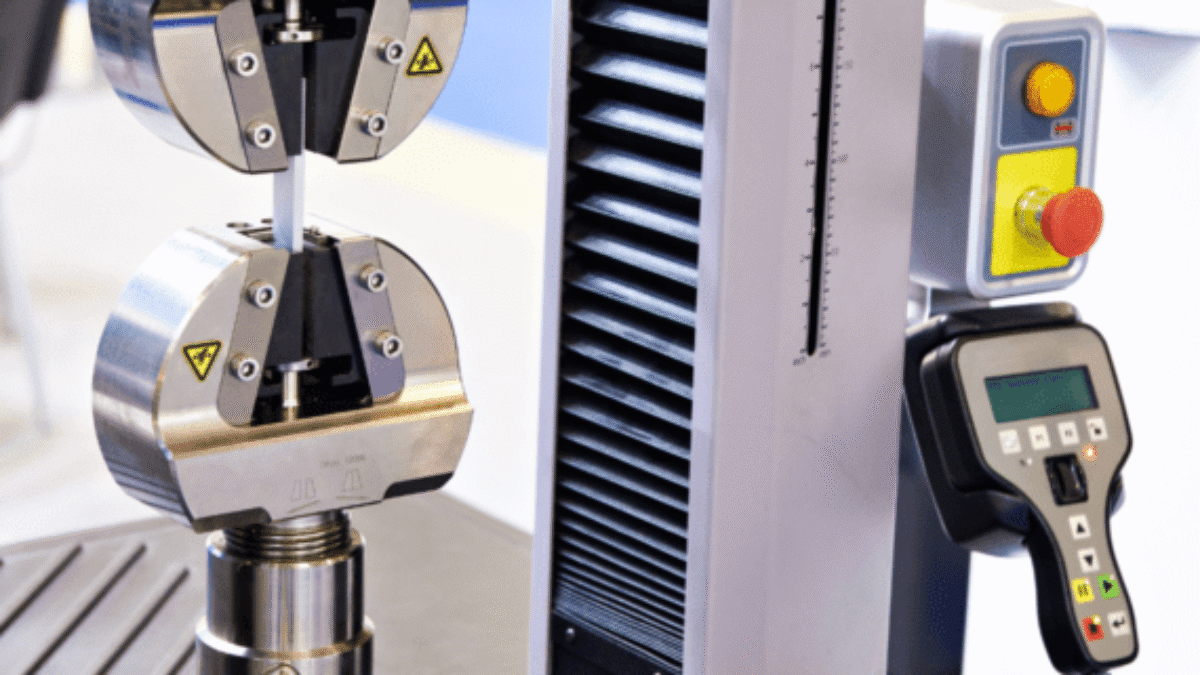

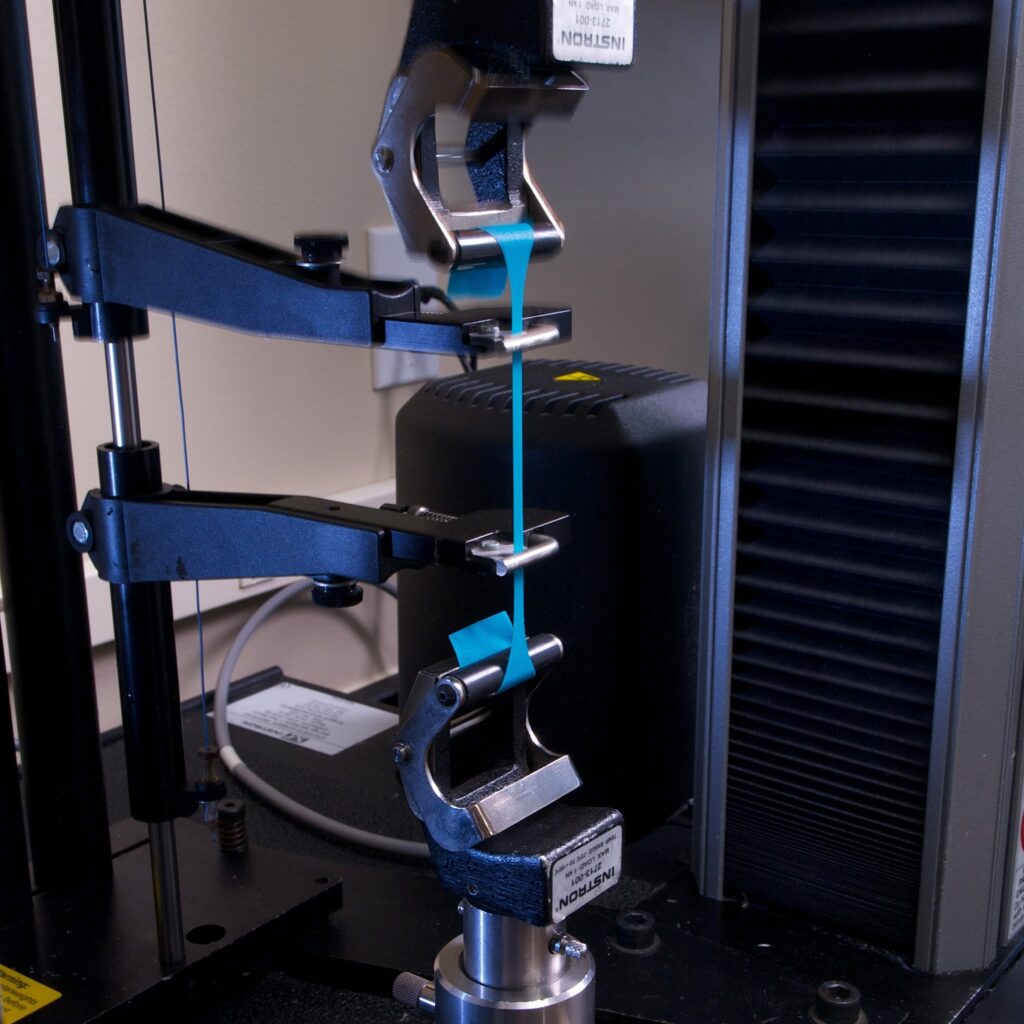

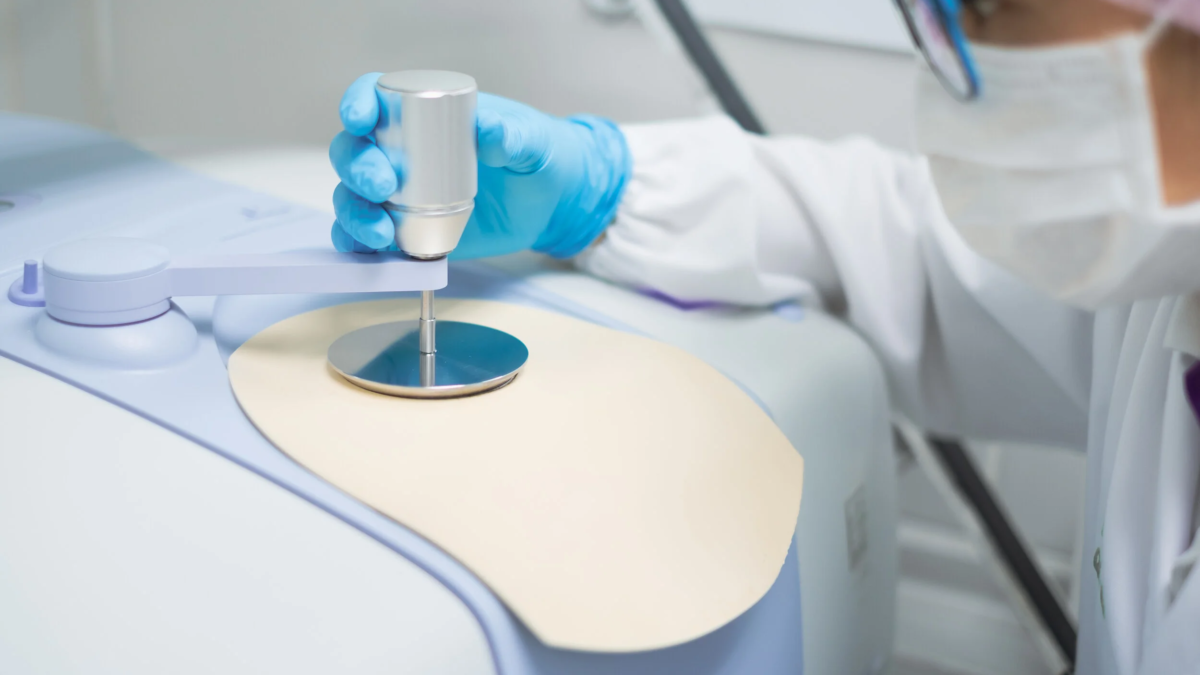

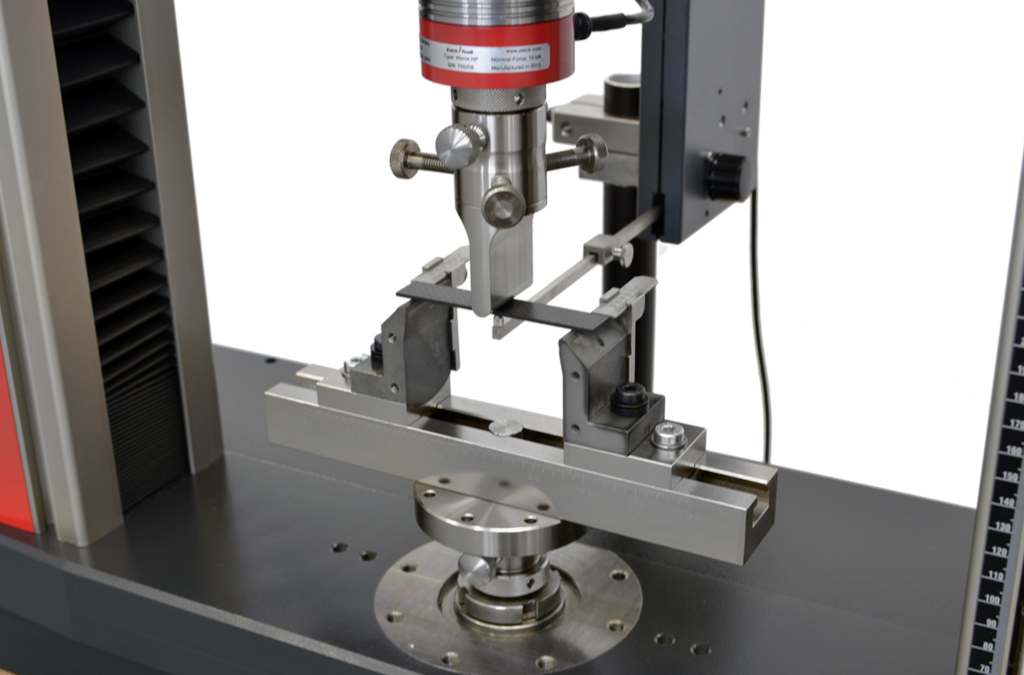

At Kiyo R&D LAB, tensile testing is performed using advanced Universal Testing Machines (UTMs) with precision load cells and extensometers. The procedure includes:

✓ Sample Preparation

Specimens are cut or molded according to ASTM/ISO dimensions.

✓ Conditioning

Samples are stabilized under controlled temperature and humidity.

✓ Accurate Clamping

To avoid slippage or premature failure, grips are matched to material type.

✓ Controlled Loading

The machine pulls the specimen at a fixed speed.

✓ Digital Data Capture

Load, elongation, and stress–strain curves are collected in real time.

✓ Expert Evaluation

Results are interpreted by trained professionals.

Our tensile testing for plastics services in India @ Kiyo R&D LAB follow globally accepted standards such as:

- ASTM D638 – Tensile Properties of Plastics

- ISO 527 – Plastics Tensile Testing

These standards ensure consistency, repeatability, and international acceptance.

Tensile Testing Applications Across Industries

Tensile testing is used in almost every industry that manufactures or uses plastic products.

1. Automotive & EV Sector

- Bumpers

- Interior trims

- Under-the-hood parts

- Fasteners & clips

- EV housings

Impact resistance is important, but tensile strength defines structural integrity.

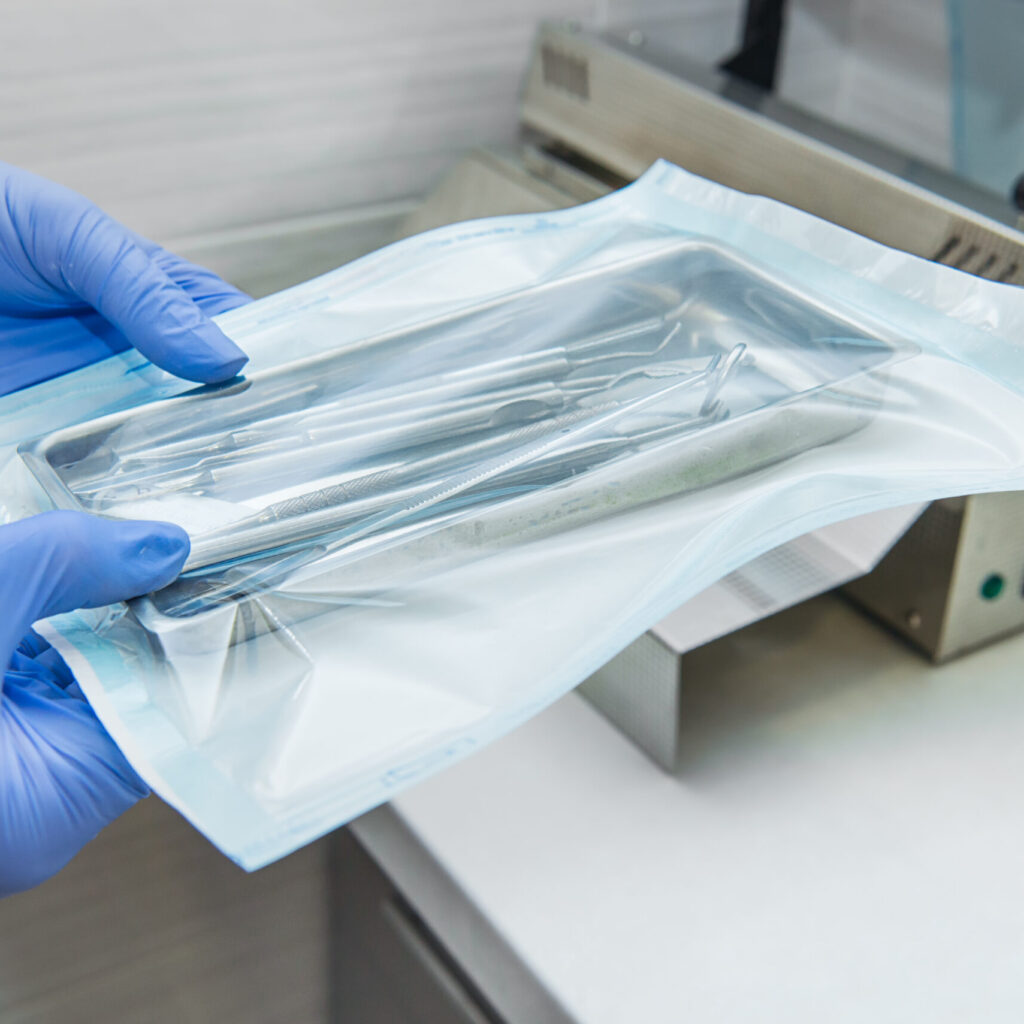

2. Packaging Industry

- HDPE/PP bottles

- PET packaging

- Rigid containers

- Films & laminates

Tensile testing ensures packaging does not tear, deform, or split during transit.

3. Electrical & Electronics

- Switch housings

- Cable ducts

- Connectors

- Appliance components

These parts must withstand mechanical stress without cracking.

4. Engineering Plastics

High-performance polymers like ABS, Nylon, PBT, PC, and composites require tensile testing for:

- R&D

- Process optimization

- Product design

5. Construction Materials

PVC pipes, composite panels, and FRP structures rely on validated tensile performance.

6. Academic & Research Institutions

Students and researchers depend on accurate tensile results for project validation, comparative analysis, and thesis work.

Common Factors that Affect Tensile Strength

Many variables influence tensile performance:

- Material type (PP vs ABS vs Nylon vs PET, etc.)

- Fillers (glass fiber, minerals, pigments)

- Processing conditions (molding temperature, pressure, cooling time)

- Sample thickness & geometry

- Environmental exposure (UV, humidity, thermal ageing)

- Recycled vs virgin material content

At Kiyo R&D LAB, we help you understand how each factor impacts your material’s tensile behavior so you can make informed decisions.

Why Choose Kiyo R&D LAB for Tensile Testing in India?

Kiyo R&D LAB has built a strong reputation for delivering accurate and reliable testing services across India. Here’s why industries trust us:

✔ NABL-Accredited Testing

Your results are officially recognized and accepted nationwide.

✔ Fast (1-Day) Report Delivery

Essential for tight production and submission deadlines.

✔ Advanced Equipment

Our UTMs provide precision data with minimal error.

✔ Expert Technical Guidance

We help you understand not just the numbers, but what they mean for your product.

✔ Student-Friendly Support

Final-year students get guidance and affordable testing packages.

✔ Multi-Test Integration

Combine tensile testing with:

- Flexural

- Impact

- Hardness

- DSC/TGA

- MFI

- Environmental ageing

to get a complete material performance profile.

Real Benefits of Tensile Testing for Your Business or Project

When you choose tensile testing for plastics services in India @ Kiyo R&D LAB, you gain:

- Better product designs

- Fewer failures during use

- Stronger quality control

- Reliable supplier verification

- Improved customer satisfaction

- Data-backed decision-making

- Accurate academic documentation

It ensures your product is not just “good,” but mechanically dependable.

Conclusion

Tensile testing is one of the most fundamental yet powerful tools in plastic material evaluation. It reveals how strong, flexible, and durable your product truly is under real-world conditions. With tensile testing for plastics services in India @ Kiyo R&D LAB, industries and students gain access to NABL-accredited results, expert analysis, and fast reporting—everything needed to ensure performance, reliability, and quality.

Whether you are developing a new product, verifying material consistency, solving a failure issue, or completing an engineering project, Kiyo R&D LAB is equipped to support your journey with precision and confidence.