When polymer products fail, soften too early, warp during processing, or behave inconsistently from batch to batch, the root cause is often thermal behavior—not visible defects. Dsc Analysis of polymers such as Melting point shifts, incomplete crystallization, or unexpected glass transition temperatures quietly undermine performance long before anyone notices a crack or deformation.

This is exactly why DSC analysis of polymers services in Chennai – Kiyo R&D LAB are critical for manufacturers, processors, and R&D teams who need clarity instead of assumptions.

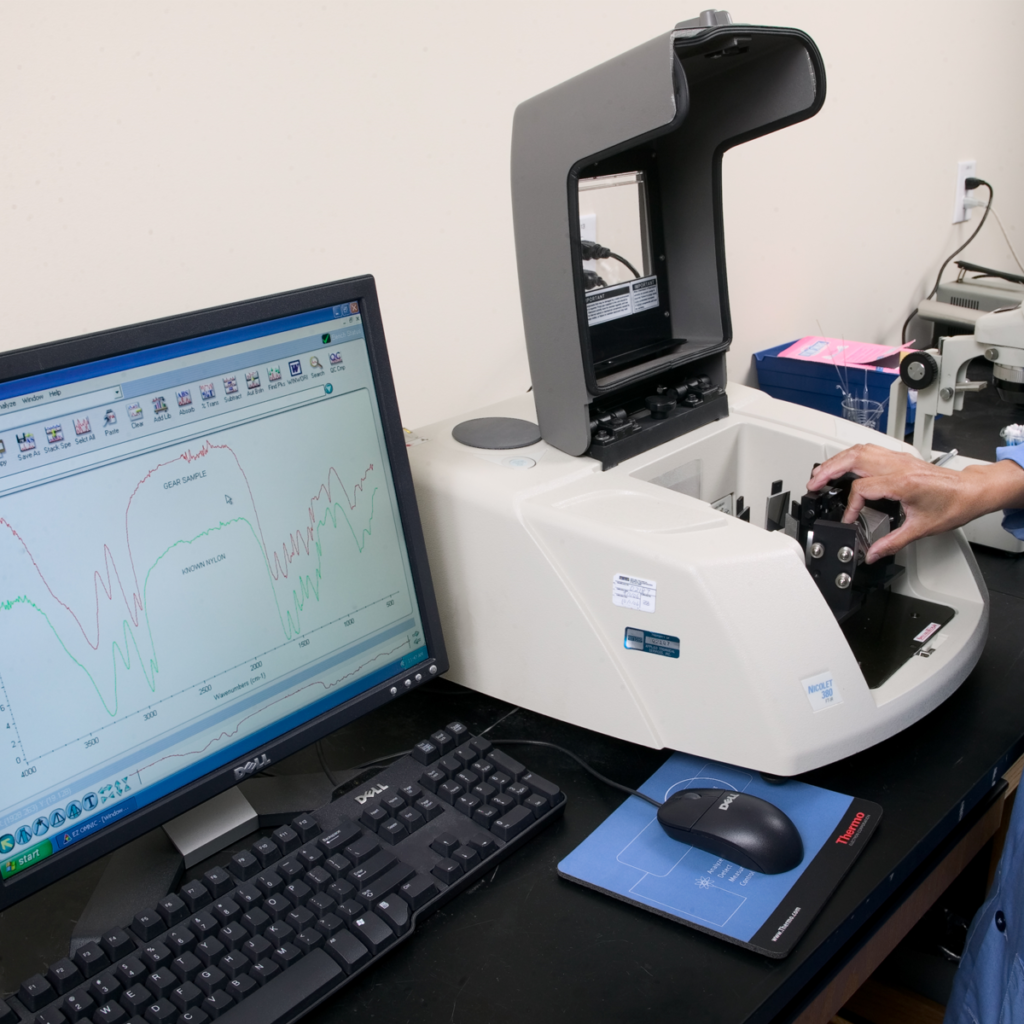

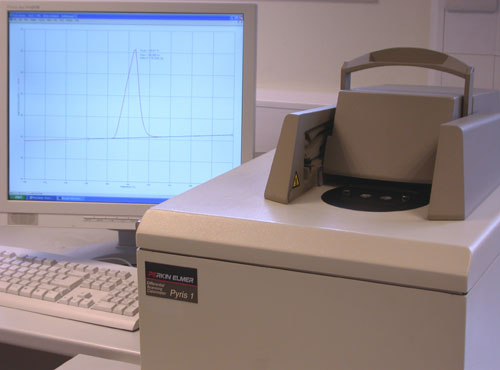

At Kiyo R&D LAB, DSC testing is treated as a decision-making tool, not just a thermal curve on a report. The goal is simple: understand how your polymer behaves when heated, cooled, and processed—because that behavior defines real-world performance.

What Is DSC Analysis of Polymers?

Differential Scanning Calorimetry (DSC) measures how a polymer absorbs or releases heat as temperature changes. In practical terms, DSC helps identify:

- Glass transition temperature (Tg)

- Melting temperature (Tm)

- Crystallization behavior

- Degree of crystallinity

- Thermal transitions caused by additives or fillers

These parameters control how a polymer flows during molding, how it solidifies, and how it performs in service. Datasheets provide typical values, but your actual material—with your processing history—often behaves differently.

Why DSC Analysis Matters in Polymer Applications

Many polymer-related problems trace back to thermal mismatch:

- Parts soften earlier than expected

- Warpage occurs after molding

- Cycle times fluctuate without explanation

- Mechanical properties vary between batches

DSC analysis reveals whether the issue is due to:

- Incorrect polymer grade

- Variation in crystallinity

- Additive or filler effects

- Improper cooling or processing conditions

Without DSC data, teams are often adjusting process parameters blindly.

Why “In Chennai” Matters for DSC Testing & DSC analysis of polymers

Searching for DSC analysis of polymers services in Chennai usually means time is critical. Manufacturers need:

- Fast sample turnaround

- Local technical discussion

- Clear interpretation—not just graphs

Kiyo R&D LAB supports Chennai-based industries—including plastics processing, automotive suppliers, packaging manufacturers, and research institutions—with accessible, locally available DSC testing and practical reporting.

Polymers Commonly Evaluated Using DSC analysis of polymers

DSC analysis at Kiyo R&D LAB is commonly performed for:

- Polypropylene (PP)

- Polyethylene (PE, HDPE, LDPE)

- Polyamide (Nylon)

- PET and engineering plastics

- Polymer blends and filled materials

Testing can be performed on raw pellets, molded parts, films, sheets, or reprocessed materials—because processing history changes thermal behavior.

What DSC Analysis Actually Tells You (Beyond Numbers)

Glass Transition Temperature (Tg)

Tg defines the temperature range where a polymer transitions from rigid to rubbery behavior. If Tg shifts, impact resistance, stiffness, and dimensional stability shift with it.

Melting Temperature (Tm)

Tm controls processing windows. A small change can explain poor flow, incomplete filling, or inconsistent molding results.

Crystallization Behavior

Crystallization temperature and enthalpy influence shrinkage, warpage, and cycle time. DSC helps compare how different batches or cooling conditions affect crystallinity.

Degree of Crystallinity

Crystallinity directly impacts stiffness, chemical resistance, and heat resistance. DSC allows relative comparison between samples—even when everything “looks the same.”

DSC Analysis of polymers in Product Development

Smart teams use DSC early, not after problems appear. During development, DSC helps:

- Compare polymer grades objectively

- Evaluate the effect of fillers or reinforcements

- Optimize processing temperatures

- Predict thermal limits before field exposure

Early DSC testing often prevents costly mold rework and repeated trial runs.

DSC Analysis of polymers for Quality Control & Batch Comparison

Batch-to-batch variation is a silent risk in polymer processing. DSC analysis helps identify:

- Changes in polymer composition

- Inconsistent crystallinity

- Effects of regrind or recycled content

- Supplier or formulation drift

DSC analysis of polymers services in Chennai – Kiyo R&D LAB provide objective thermal fingerprints that help quality teams confirm consistency—or detect problems early.

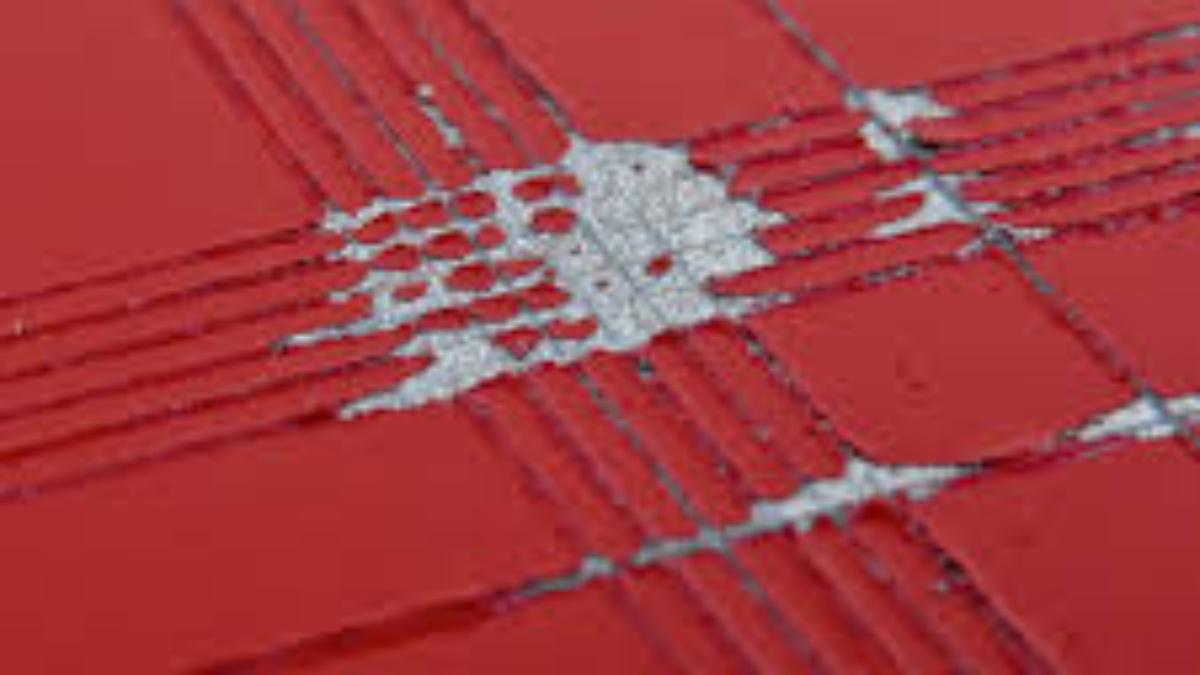

DSC Analysis of polymers in Failure Investigation

When a polymer part fails unexpectedly—softening, warping, or losing strength—DSC often reveals what mechanical tests cannot. Changes in Tg, Tm, or crystallinity point directly to:

- Overheating during processing

- Incorrect material substitution

- Thermal degradation

- Improper cooling cycles

DSC turns failure analysis from speculation into measurable evidence.

Standards-Based DSC Testing

At Kiyo R&D LAB, DSC testing is performed using controlled methods aligned with relevant ASTM, ISO, or customer-defined procedures, depending on application needs.

Standards-based testing ensures:

- Repeatable results

- Comparable data across samples

- Acceptance in audits and customer reviews

A thermal curve without method control is just a picture. With standards, it becomes evidence.

What Makes a DSC Report Useful?

A good DSC report does more than show peaks. It should clearly state:

- Sample identity and condition

- Test method and heating/cooling rates

- Observed transitions and enthalpy values

- Practical interpretation relevant to processing and performance

At Kiyo R&D LAB, reports are written so engineers and production teams can use the data, not just file it.

Why Choose Kiyo R&D LAB for DSC Analysis of polymers?

Many labs can generate DSC curves. Fewer labs help you understand what those curves mean for your product.

Kiyo R&D LAB stands out because:

- Testing is application-driven, not generic

- Real products and processed samples are evaluated

- Results are explained in practical terms

- Data is linked to processing and performance decisions

This approach reduces guesswork and accelerates problem-solving.

Who Needs DSC Analysis of Polymers?

DSC analysis of polymers services in Chennai – Kiyo R&D LAB are essential for:

- Plastic processors and molders

- Automotive and packaging suppliers

- R&D and product development teams

- Quality and supplier management teams

- Startups working with new polymer formulations

If thermal behavior affects your product’s performance, DSC testing is not optional.

Final Thoughts

Polymers don’t behave randomly—they behave according to their thermal history. DSC analysis reveals that history and turns hidden transitions into actionable data. Whether you are developing a new product, troubleshooting a processing issue, or validating material consistency, DSC analysis of polymers services in Chennai – Kiyo R&D LAB provide the clarity needed to move forward confidently.

In polymer engineering, thermal understanding is not an advantage—it’s a requirement.