Abrasion Resistance As Per MS 343-16

How MS 343-16 Abrasion Resistance Testing Validates Material Performance

Introduction

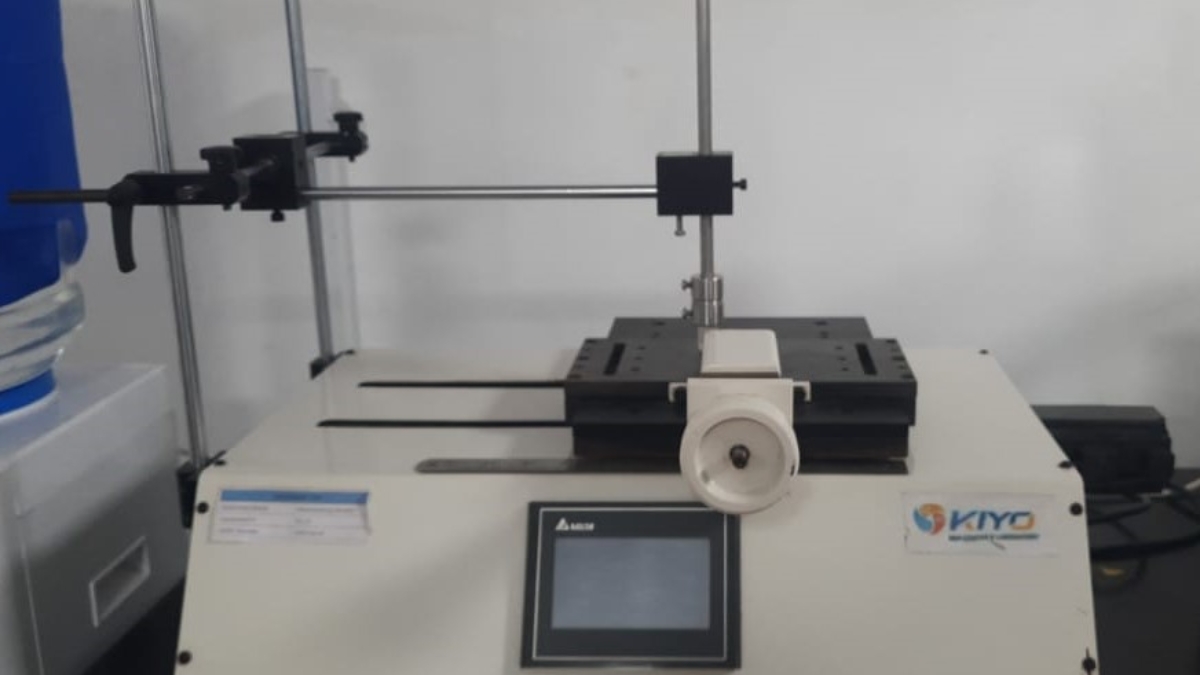

- In a world where product reliability and longevity are non-negotiable, understanding how materials respond to wear and tear is vital. Abrasion Resistance Testing, especially when conducted as per MS 343-16, plays a central role in determining how long a product will last when exposed to repeated frictional forces. At Kiyo R&D Center & Laboratory, we specialize in providing this essential test with precision, helping industries verify that their materials meet durability expectations under real-world conditions.

🧩 The Role of MS 343-16 in Product Validation

MS 343-16 is more than just a test method—it’s a performance benchmark. Whether you’re producing a car dashboard, a shoe sole, or an industrial gasket, the ability of that component to resist surface wear determines its practical value.

This Malaysian standard ensures testing is repeatable, reliable, and applicable across a broad range of polymer-based products.

🧪 Test Principles: Simulating Real-Life Wear

The MS 343-16 method evaluates how a material reacts when an abrasive force is applied in a controlled, repetitive manner. Our process includes:

Securing the sample on a reciprocating platform

Using a standardized abrasive material (e.g., sandpaper)

Applying constant load and motion cycles

Quantifying the wear by visual inspection or weight loss

This approach effectively mimics the kinds of friction that occur during product usage, offering a realistic prediction of in-field performance.

🚀 Where It Matters Most: Real-World Applications

Some real-life scenarios where abrasion resistance is critical include:

Automotive trims and interior parts – where consistent touch points lead to surface degradation.

Footwear soles – which must endure continuous contact with rough surfaces.

Consumer electronics casings – to maintain aesthetics and durability.

Seals and gaskets – especially in mechanical systems with moving parts.

Testing to MS 343-16 helps engineers and designers make better choices about material selection and product design.

📊 Turning Data into Action

Once testing is complete, the results allow stakeholders to:

Identify material weaknesses early in the design stage

Optimize compositions or coatings for improved performance

Meet regulatory or client-specific durability standards

Reduce warranty claims and product returns

At Kiyo R&D Lab, we provide detailed test reports with quantitative wear data, failure observations, and recommendations.

🌟 Why Trust Kiyo R&D Center?

We bring a combination of:

✔️ Advanced testing infrastructure

✔️ Adherence to local and international standards

✔️ Experienced materials scientists and lab technicians

✔️ A commitment to quality and innovation

🧭 Future-Proof Your Products

- Abrasion resistance isn't just about toughness—it's about trust. With MS 343-16 testing from Kiyo R&D Center & Laboratory, you ensure your products not only look good but last longer under the pressures of everyday use.