Bitumen Flash Point Test Services

Reliable Bitumen Flash Point Testing in Chennai – Kiyo R&D LAB

Introduction

Bitumen is the backbone of modern road construction, waterproofing, and pavement engineering. It binds aggregates together, provides durability, and ensures smooth, long-lasting roads. But behind every strong highway lies a critical safety parameter that many contractors overlook — flash point. If bitumen is overheated during storage, mixing, or transportation, it can release flammable vapors that may ignite suddenly, causing fires, equipment damage, and serious workplace accidents. That is why bitumen flash point test services in Chennai – Kiyo R&D LAB are not just a laboratory formality — they are a safety necessity for every road construction and asphalt manufacturing company. At Kiyo R&D LAB, flash point testing is treated as a precision safety assessment, not a routine checklist. We help contractors, suppliers, and manufacturers ensure that their bitumen is safe to heat, handle, and use — before accidents happen.

Why Bitumen Flash Point Testing Matters

Many road contractors focus only on penetration grade, softening point, or ductility of bitumen. While these are important, they do not tell you whether the material is safe to heat.

Bitumen is often heated to 150–170°C during mixing and paving. If its flash point is too low, vapors can ignite near open flames, heaters, or electrical sparks.

That is why bitumen flash point test services in Chennai – Kiyo R&D LAB are essential for:

Preventing fire hazards at hot mix plants

Ensuring safe bitumen heating and handling

Reducing risk of workplace accidents

Meeting safety and regulatory requirements

Avoiding insurance and legal liabilities

Protecting workers, equipment, and infrastructure

If your asphalt plant or storage tank has ever produced smoke, fumes, or overheating issues, flash point testing should be mandatory in your quality process.

What Is Bitumen Flash Point?

The flash point of bitumen is the lowest temperature at which its vapors ignite momentarily when exposed to a small flame under controlled conditions.

In simple terms:

Below flash point → bitumen is relatively safe

At flash point → vapors can ignite

Above flash point → higher fire risk

That is why industries rely on bitumen flash point test services in Chennai – Kiyo R&D LAB to confirm safe operating temperatures before using bitumen in large-scale projects.

Standard Methods Used for Flash Point Testing

At Kiyo R&D LAB, bitumen flash point testing follows internationally recognized standards, including:

IS 1209 (Part 1) – Pensky-Martens Closed Cup Method

ASTM D93 – Flash Point by Pensky-Martens Closed Cup

IP 34 – Petroleum products flash point testing

These standards ensure that results from bitumen flash point test services in Chennai – Kiyo R&D LAB are reliable, comparable, and acceptable for audits, tenders, and quality approvals.

How the Flash Point Test Is Performed

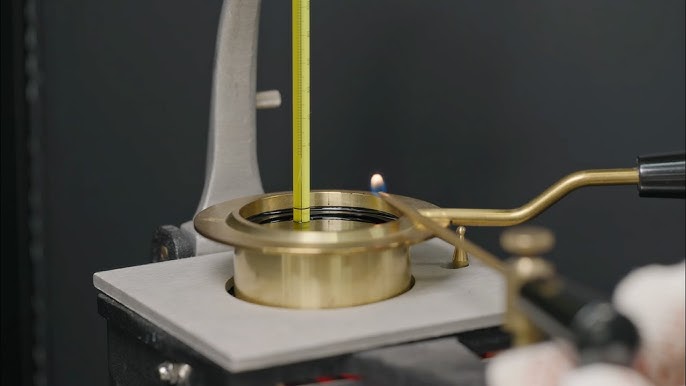

The process is scientific and carefully controlled:

A bitumen sample is placed in a closed cup apparatus.

The temperature is gradually increased at a controlled rate.

At regular intervals, a small flame is introduced above the sample surface.

The lowest temperature at which a flash occurs is recorded as the flash point.

This method closely simulates real heating conditions in asphalt plants, making bitumen flash point test services in Chennai – Kiyo R&D LAB highly relevant to actual field operations.

Why Chennai Industries Prefer Kiyo R&D LAB

Chennai is a major hub for road construction, infrastructure projects, and asphalt manufacturing. Yet not all laboratories offer precise, standard-compliant flash point testing.

This is why bitumen flash point test services in Chennai – Kiyo R&D LAB stand out.

Key advantages of Kiyo R&D LAB:

NABL-accredited testing environment

Calibrated Pensky-Martens apparatus

Experienced materials scientists

Strict adherence to IS/ASTM/IP standards

Fast turnaround time

Clear, easy-to-understand test reports

Technical support for contractors and consultants

At Kiyo R&D LAB, you get safety assurance — not just a number on paper.

Who Needs Bitumen Flash Point Testing?

You should use bitumen flash point test services in Chennai – Kiyo R&D LAB if you are in:

1. Road Construction & Infrastructure

National highways

State highways

City roads

Airport runways

2. Hot Mix Asphalt Plants

Batch mix plants

Drum mix plants

Asphalt contractors

3. Bitumen Suppliers & Refineries

Bitumen producers

Bulk storage tank operators

Transporters

4. Waterproofing & Roofing Contractors

Bitumen-based membranes

Industrial waterproofing applications

If you heat bitumen in any form, flash point testing is critical.

How Flash Point Testing Saves You Money

Many contractors skip testing to save small costs. That is a dangerous and expensive mindset.

A single fire incident at an asphalt plant can cost lakhs in:

Equipment damage

Production downtime

Worker compensation

Insurance claims

Legal penalties

Using bitumen flash point test services in Chennai – Kiyo R&D LAB helps you:

Avoid fire accidents

Reduce operational risks

Improve plant safety compliance

Protect workers and machinery

Strengthen contractor credibility

In simple terms: testing costs little; accidents cost a fortune.

Relationship Between Flash Point and Other Bitumen Properties

Flash point is closely linked to:

Volatile content

Heating history of bitumen

Storage conditions

Grade of bitumen (VG 10, VG 30, VG 40, etc.)

If a batch of bitumen has been overheated or contaminated, flash point values often drop — a clear warning sign that contractors should not ignore.

That is why bitumen flash point test services in Chennai – Kiyo R&D LAB are often combined with penetration, softening point, and viscosity tests for complete quality assurance.

Common Problems Detected by Flash Point Testing

Flash point testing often reveals issues such as:

Overheated bitumen during transport

Poor storage conditions

Contamination with lighter oils

Inferior bitumen grade

Excessive volatile content

If your bitumen behaves unpredictably during heating, flash point testing will expose the real issue.

The Reality Many Contractors Ignore

Many road contractors make risky assumptions:

They trust supplier claims blindly

They skip incoming inspection

They assume all bitumen is safe to heat

They test only after accidents occur

Smart contractors use bitumen flash point test services in Chennai – Kiyo R&D LAB proactively before using any new batch of bitumen.