Dart Impact Tester Services

Reliable Dart Impact Tester in Chennai for Plastic Films – Kiyo R&D LAB

Introduction

Plastic films, sheets, and flexible packaging materials are everywhere — food pouches, industrial liners, carry bags, shrink wraps, protective covers, pharmaceutical blisters, and multilayer laminates. Yet one simple reality is often ignored: these materials look strong but can fail suddenly when struck by an impact. A small accidental drop, sharp corner, or sudden load can tear or puncture the film, causing leakage, contamination, product loss, or customer complaints. That is exactly why dart impact tester services in Chennai – Kiyo R&D LAB have become critical for packaging manufacturers, polymer processors, and material suppliers who take performance seriously. Dart impact testing is one of the most practical and industry-relevant tests for evaluating the toughness and puncture resistance of plastic films and sheets. If your packaging must survive handling, transportation, stacking, and real-world abuse, you cannot skip dart impact testing. At Kiyo R&D LAB, dart impact testing is not treated as a routine lab exercise — it is treated as a reliability check that protects your product, brand, and customer trust.

Why Dart Impact Tester Really Matters

Many companies design packaging based only on thickness or tensile strength. That is a dangerous assumption.

A film can have high tensile strength but still fail catastrophically under sudden impact.

That is why dart impact tester services in Chennai – Kiyo R&D LAB are essential for anyone manufacturing or using plastic films.

Dart impact testing helps you:

Predict real-world puncture resistance

Reduce packaging failures during transport

Prevent product leakage and contamination

Improve durability of food and pharma packaging

Validate supplier film quality

Optimize material grade selection

Reduce customer complaints and returns

Support compliance with global standards

If your product has ever failed in transit or storage, you already understand the value of proper impact testing.

What Is a Dart Impact Tester?

Dart impact testing evaluates how much energy a plastic film can absorb before puncturing.

A weighted dart is dropped from a controlled height onto a clamped film specimen. The weight at which the film fails indicates its impact resistance.

This method closely simulates real-life accidental impacts that occur during:

Handling

Stacking

Forklift movement

Transportation

Loading and unloading

That is why industries trust dart impact tester services in Chennai – Kiyo R&D LAB — because the test reflects real-world performance, not just lab theory.

Standards Followed in Dart Impact Tester

At Kiyo R&D LAB, dart impact testing is conducted strictly according to recognized international standards such as:

ASTM D1709 – Standard Test Methods for Impact Resistance of Plastic Film

ISO 7765-1 & 7765-2 – Impact resistance of plastic films

IS standards (where applicable)

This ensures that results from dart impact tester services in Chennai – Kiyo R&D LAB are acceptable to customers, auditors, and regulatory bodies.

Types of Dart Impact Tester Methods

Two main test procedures are commonly used:

1. Method A – Staircase Method

Uses multiple specimens

Adjusts dart weight based on pass/fail results

More accurate for quality control

Suitable for critical applications

2. Method B – Up-and-Down Method

Faster testing approach

Uses fewer samples

Good for routine quality checks

Kiyo R&D LAB selects the most appropriate method based on your material type, thickness, and application.

Which Industries Need Dart Impact Tester?

You should use dart impact tester services in Chennai – Kiyo R&D LAB if you are in:

1. Flexible Packaging Industry

Food pouches

Sachets

Laminated films

Shrink wraps

Industrial liners

2. Pharmaceutical Packaging

Medicine blister packs

Sterile packaging films

Medical-grade laminates

3. Plastic Film Manufacturers

LDPE, HDPE, LLDPE films

Multilayer barrier films

Stretch and shrink films

4. E-commerce and Logistics Packaging

Courier bags

Protective wraps

Shipping films

If your packaging must survive real handling, dart impact testing is non-negotiable.

Why Chennai Industries Prefer Kiyo R&D LAB

Chennai is a major hub for plastics, packaging, automotive, and polymer industries. Yet not every lab offers reliable, standard-compliant dart impact testing.

This is why dart impact tester services in Chennai – Kiyo R&D LAB stand out.

Key advantages of Kiyo R&D LAB:

NABL-accredited testing environment

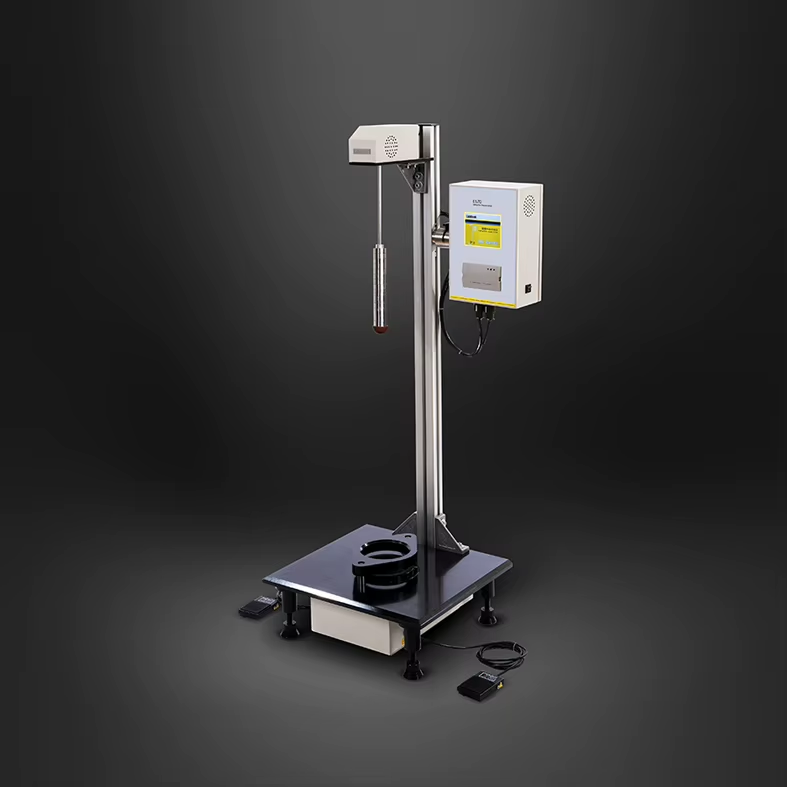

Modern, calibrated dart impact tester

Experienced materials scientists and technicians

Standard-based testing procedures

Fast turnaround time

Clear, easy-to-understand reports

Support for final-year engineering projects

At Kiyo R&D LAB, you don’t just get numbers — you get meaningful interpretation.

How Dart Impact Tester Helps You Save Money

Many companies avoid testing to save small costs. That is a false economy.

A single packaging failure can cost far more than multiple lab tests.

Using dart impact tester services in Chennai – Kiyo R&D LAB helps you:

Avoid product leakage losses

Reduce warranty claims

Minimize returns and complaints

Prevent brand reputation damage

Improve supplier accountability

Optimize material usage without over-designing

In simple terms: testing costs little; failure costs a lot.

How Kiyo R&D LAB Conducts Dart Impact Tester

The process is structured and professional:

You submit your film or sheet sample

Kiyo R&D LAB reviews thickness and material type

Appropriate test method is selected

Testing is performed using calibrated equipment

You receive a detailed technical report

Optional: guidance on material improvement

This ensures that dart impact tester services in Chennai – Kiyo R&D LAB deliver real engineering value.

Common Problems Detected by Dart Impact Testing

Dart impact testing often reveals issues such as:

Brittle film behavior

Poor polymer grade selection

Inadequate film thickness

Weak interlayer bonding in laminates

Poor extrusion or blowing process

Improper additive usage

If your packaging fails unexpectedly, dart impact testing will help pinpoint the root cause.

The Reality Many Manufacturers Ignore

Most companies test only after a failure occurs.

Typical mistakes include:

Trusting supplier datasheets blindly

Skipping incoming film inspection

Relying only on tensile strength

Ignoring real-world impact conditions

Smart companies use dart impact tester services in Chennai – Kiyo R&D LAB proactively before mass production.