Friction Coefficient Testing in Chennai

Friction Coefficient Testing in Chennai: Ensuring Performance & Reliability in Materials

Introduction

- In the world of materials engineering, understanding how surfaces interact is essential. Whether it's a plastic film used in packaging or a rubber seal in an automotive part, how these materials slide against each other can make or break product performance. That’s where friction coefficient testing comes into play—a critical analysis widely adopted across Chennai's diverse industrial sectors.

What is Friction Coefficient Testing?

The coefficient of friction (COF) represents the resistance encountered when one material slides over another. It’s typically divided into:

Static COF – resistance before motion begins

Kinetic COF – resistance during movement

This testing helps determine surface behavior, especially in manufacturing, packaging, automotive, and construction applications. For instance, in flexible packaging, too much friction can hinder machine processing, while too little can cause stacks to slip.

Why is Friction Testing Important in Chennai?

Chennai, being one of India’s prominent industrial hubs, hosts a wide array of sectors where friction plays a key role—automotive, plastics, rubber, textiles, and even electronics. In such industries, the precise understanding of friction is necessary for:

Enhancing product reliability

Meeting safety standards

Improving process efficiency

Ensuring regulatory compliance (e.g., ASTM D1894)

Manufacturers rely on local testing labs to provide insights into how materials will behave in real-world applications.

Industries That Benefit Most

- Automotive – For components like seals, belts, and interior parts, friction analysis ensures performance and wear resistance.

- Packaging – Film rolls must have consistent friction to run smoothly through machines.

- Rubber and Tyres – Understanding tire-road or sealant-substrate interaction helps improve safety and durability.

- Consumer Goods – From bottle caps to household tools, product feel and function often depend on surface friction.

How Is It Tested?

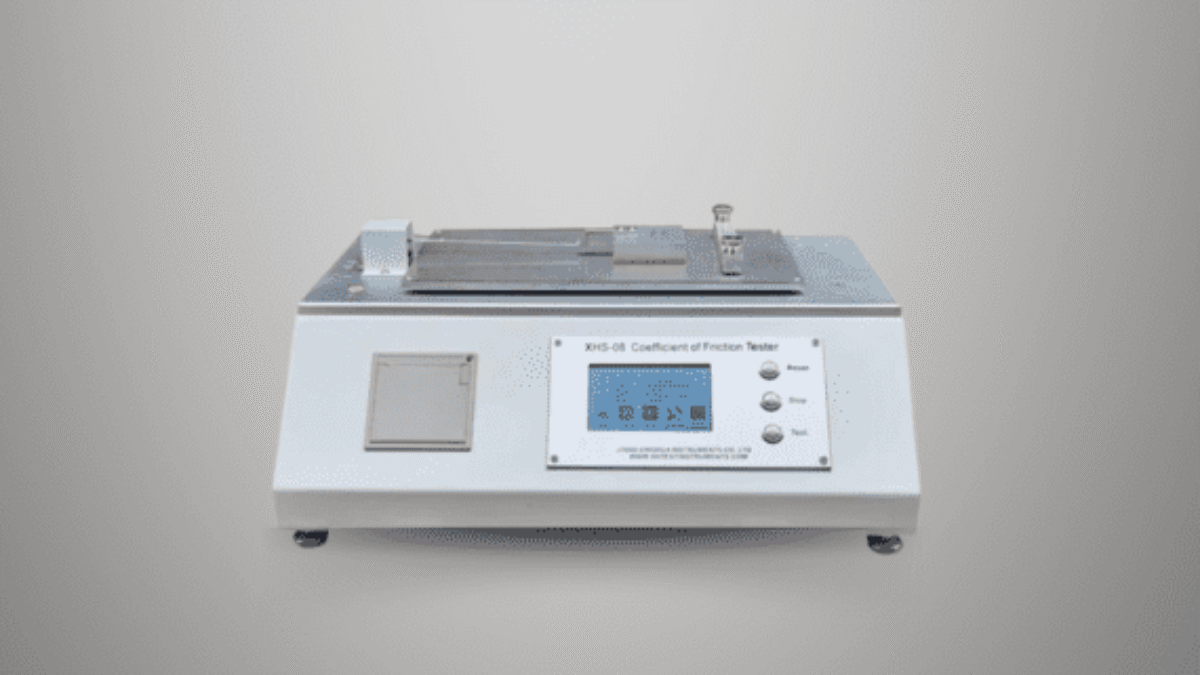

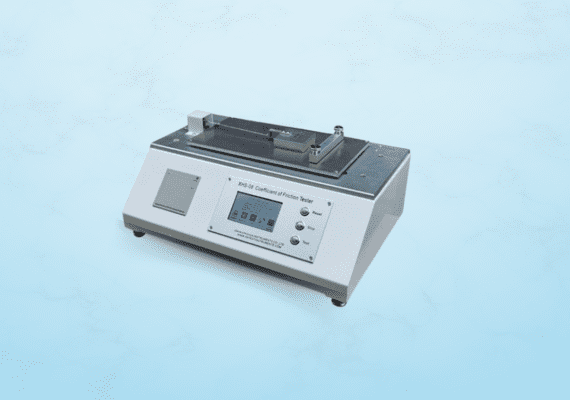

Most testing facilities in Chennai follow standardized methods, especially ASTM D1894. The test involves placing a test sample on a platform and dragging a sled with a known weight across its surface. Instruments measure the force required to initiate and maintain motion, thereby calculating static and kinetic coefficients.

Advanced testers provide digital output, graphs, and in some cases, integrate environmental conditioning for high-precision testing under different temperatures and humidity levels.

Leading Providers in Chennai

Chennai has an evolving network of NABL-accredited laboratories and testing companies that offer friction coefficient testing. Facilities like Kiyo R&D Center & Laboratory specialize in plastic, rubber, and metal material testing, including friction analysis. Other industrial labs offer similar services with added capabilities for data interpretation and material advisory.

Choosing the Right Lab

When selecting a lab in Chennai for friction testing, look for:

Accreditation and adherence to international standards (e.g., ASTM, ISO)

Range of materials handled (films, elastomers, composites, etc.)

Speed of reporting and data accuracy

Expert consultation for process optimization

Conclusion

- Friction coefficient testing is more than just a quality check—it's a window into how materials interact and perform. For Chennai’s manufacturing and R&D-driven industries, it offers vital insights that enhance safety, product integrity, and compliance. Whether you’re developing a new product or refining an existing one, investing in proper friction analysis can make a world of difference.