Stain Resistance Testing In Chennai

Elevate Product Quality with Stain Resistance Testing in Chennai – Kiyo R&D Center & Laboratory

Introduction

- In today's highly competitive market, the aesthetic durability of a product can be just as critical as its mechanical strength. Stain resistance is a defining quality, especially in industries where surface cleanliness and longevity matter—think automotive interiors, consumer electronics, home appliances, and architectural materials.

Understanding Stain Resistance Testing

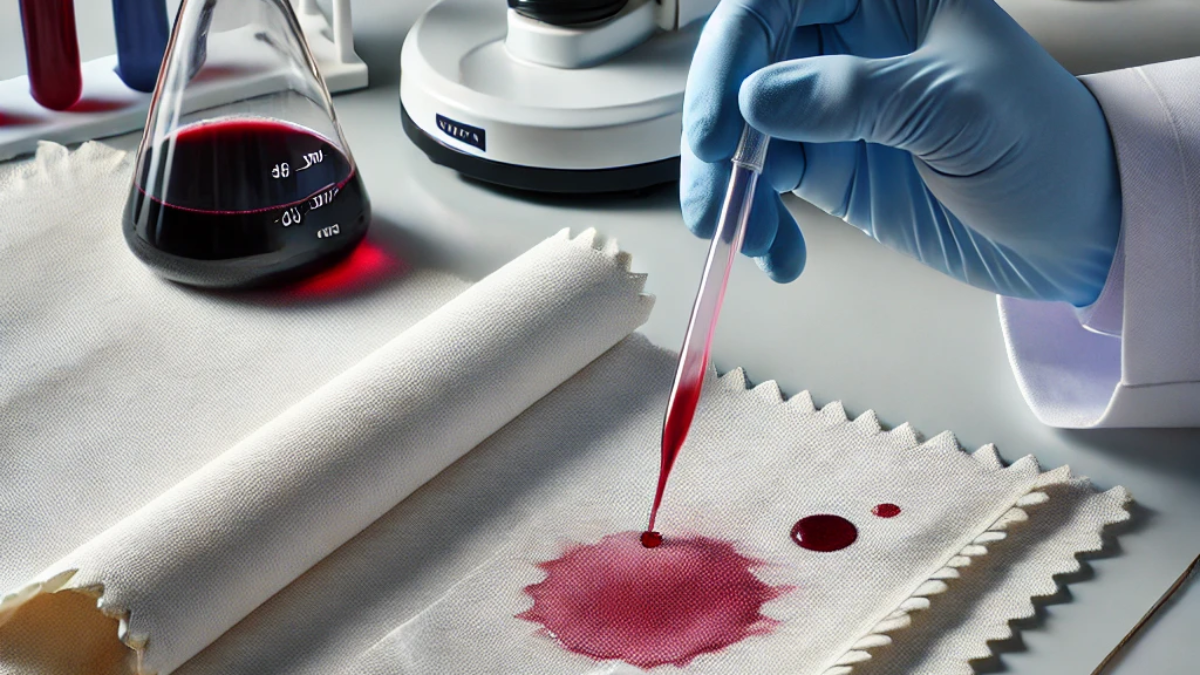

Stain resistance testing evaluates a material’s capability to withstand staining substances such as oils, inks, food spills, or chemicals. The results help manufacturers enhance product performance, ensuring surfaces remain pristine after prolonged use or exposure to harsh environments.

Why Chennai-Based Kiyo R&D is the Trusted Testing Partner?

Kiyo R&D Center & Laboratory stands out with its cutting-edge facilities and commitment to global quality benchmarks. Whether you’re validating a new product or refining an existing one, our tests ensure compliance with leading standards such as:

MS 343-16 (Malaysia’s national plastic material standard)

ISO 105 series (international textile and surface performance standards)

ASTM D1308, ASTM D4828 (standard methods for coatings and washable fabrics)

Testing Procedure Highlights

Our stain resistance testing methodology includes:

- Preparing and conditioning the material sample.

- Applying specified staining agents like coffee, ink, or sebum.

- Allowing exposure time as defined by the relevant standard.

- Cleaning the sample and evaluating discoloration or residual staining.

- Reporting results using color change scales or visual grading metrics.

Industries That Benefit Most

Automotive: Ensuring interiors maintain their finish and appeal.

Textiles: Validating fabric performance against common household stains.

Construction Materials: Testing coatings and laminates used in kitchens, hospitals, and public spaces.

Consumer Goods: Improving resistance of gadgets, plastics, and appliances to daily wear.

Why Standards Matter: MS 343-16, ISO & ASTM ?

Compliance isn’t just a regulatory checkbox—it’s a quality guarantee. At Kiyo R&D, every stain resistance test adheres to the most relevant and updated standards:

MS 343-16 ensures testing procedures for plastics used in Malaysia’s industries are robust and traceable.

ISO 105-X12 and ISO 105-A03 provide consistent methods for evaluating stain fastness in textiles.

ASTM D1308 and D4828 test surface coatings and fabrics under practical, reproducible conditions.

Start Your Stain Resistance Testing with Kiyo R&D Today

Our lab in Chennai delivers fast, accurate, and insightful reports tailored to your industry needs. Whether you’re developing new materials or improving existing formulations, we provide the technical support you need to meet market expectations.

Conclusion

- In a market where durability and aesthetics define product success, stain resistance testing is not just an option—it's a necessity. At Kiyo R&D Center & Laboratory in Chennai, we combine advanced testing capabilities with strict adherence to MS 343-16, ISO, and ASTM standards to ensure your materials perform flawlessly under real-world conditions. Whether you're in automotive, construction, textiles, or consumer products, our tailored testing services provide the reliability and insights you need to innovate with confidence. Partner with Kiyo R&D and set your product apart through quality that lasts.