Plastic Product Testing Lab

Performance Testing for Automotive Door Outside Handles: Ensuring Quality and Longevity

Introduction

- In the car global, every component contributes to the general protection, reliability, and consumer enjoy of a vehicle. One component that endures normal use and faces a whole lot of environmental demanding situations is the door out of doors cope with. Often ignored in phrases of its importance, this issue performs a key position within the functionality and comfort of a vehicle. To ensure that automobile door handles crafted from plastic can withstand day by day use and cruel environmental conditions, performance testing is important. At our Plastic Product Testing Lab, we specialize in evaluating the overall performance and sturdiness of plastic components utilized in cars, consisting of door handles. This weblog will explore the significance of overall performance trying out for door handles and the important thing exams we behavior to guarantee their reliability and energy.

The Need for Door Handle Performance Testing

Automotive door handles are subjected to a whole lot of stresses—mechanical forces from ordinary use, exposure to fluctuating temperatures, and get in touch with with environmental elements like UV rays and moisture. If a door cope with fails, it no longer best impacts the consumer revel in however also can gift a safety threat.

Performance testing is crucial because it allows:

- Enhance Durability: Handles ought to characteristic smoothly over the automobile’s lifespan without breaking, cracking, or deforming.

- Ensure User Safety: Handles need to perform reliably, even underneath stress, to avoid any protection risks associated with malfunctioning components.

- Verify Compliance with Standards: Testing guarantees that door handles meet automotive enterprise guidelines for strength, impact resistance, and fabric integrity.

Critical Performance Tests for Door Outside Handles

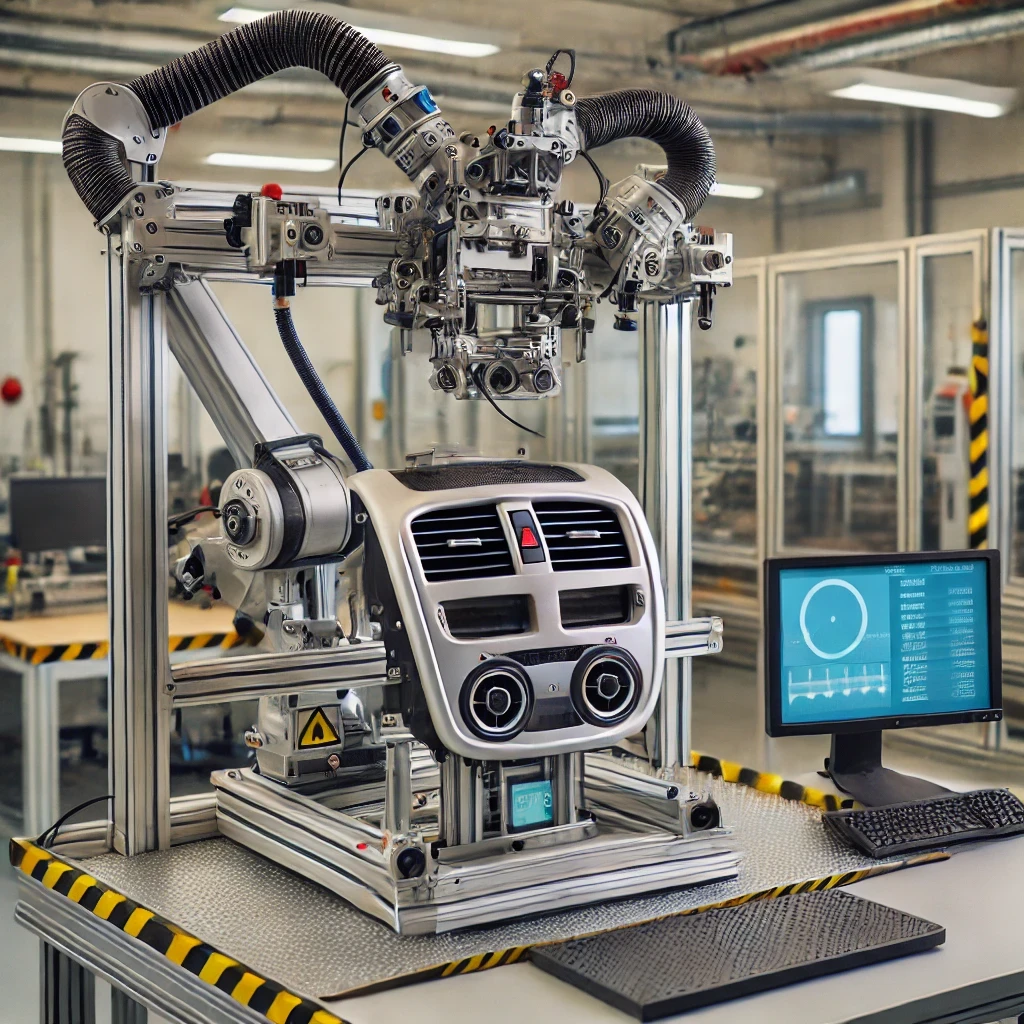

To assure that plastic door handles are strong and can endure real-world situations, our lab plays numerous rigorous overall performance checks. Each take a look at is designed to copy the stresses handles will encounter in normal use and excessive conditions.

1. Tensile Testing

Tensile testing evaluates the strength of the plastic fabric whilst subjected to pulling forces. This check simulates the strain implemented when a person pulls on the door take care of to open the car. It facilitates manufacturers decide the most force the cope with can tolerate without breaking or deforming, ensuring it can endure every day utilization.

2. Impact Resistance Testing

Impact resistance trying out measures the door deal with’s capability to resist sudden shocks or blows. This test is crucial for assessing how the manage reacts when a door is slammed shut or in minor collisions. It facilitates make sure the deal with remains purposeful and intact, even if subjected to surprising forces.

3. Fatigue Testing

Over time, the repeated use of door handles can result in cloth fatigue, causing cracks or structural weakness. Fatigue checking out replicates the manage’s day by day operation with the aid of making use of cyclical pressure to it, simulating hundreds of open-and-near cycles. The intention is to evaluate how long the cope with can endure repetitive mechanical stresses without displaying signs and symptoms of damage.

4. Thermal and Environmental Resistance Testing

Thermal testing topics the door take care of to a wide range of temperatures to evaluate its performance in intense warmness and cold. Automotive door handles must hold their structural integrity and functionality whether or not exposed to freezing iciness situations or the blazing summer sun. This check additionally consists of humidity resistance to make certain the deal with does now not warp, crack, or degrade whilst exposed to moisture over time.

5. UV and Weathering Testing

Outdoor car components like door handles are constantly exposed to daylight, that can degrade plastic materials over the years. UV trying out simulates extended exposure to sunlight to evaluate the handle’s resistance to UV radiation. This guarantees that the plastic won’t grow to be brittle, discolored, or weakened due to lengthy-term sun exposure.

6. Chemical Resistance Testing

Automotive door handles frequently come into touch with quite a few chemical substances, consisting of cleaning merchandise, fuel, oil, and street salts. Chemical resistance checking out ensures that the plastic material used for the handle does not deteriorate or lose its aesthetic and practical properties while uncovered to those substances.

The Benefits of Comprehensive Performance Testing

By carrying out thorough overall performance checks on door handles, automobile producers can drastically enhance product reliability and customer satisfaction. Key blessings of working with a professional testing lab consist of:

- Increased Product Lifespan: Testing guarantees that door handles can face up to years of use, minimizing the danger of failure or the need for replacements.

- Enhanced Safety and Reliability: Through rigorous checking out, manufacturers can be confident that door handles will characteristic nicely below ordinary and excessive situations, ensuring vehicle occupants’ safety.

- Regulatory Compliance: Our testing services help ensure that every one automotive additives meet industry standards and policies, decreasing the danger of non-compliance issues.

- Cost Efficiency: Identifying weaknesses in substances or layout early thru trying out allows producers avoid high-priced product recalls or redesigns

Conclusion

- In the automotive industry, making sure the sturdiness, protection, and functionality of every thing is essential. Performance testing of door outdoor handles plays a vital role in verifying that those elements can face up to every day use and environmental demanding situations. At our Plastic Product Testing Lab, we use advanced strategies to assess the electricity, resilience, and durability of plastic door handles, helping producers produce reliable, tremendous additives.