Melt Flow Index Test As Per Standard ASTM D1238

Unlocking the Value of Melt Flow Index Testing with ASTM D1238

Introduction

- In the world of plastic manufacturing, understanding how a polymer behaves during processing is crucial for ensuring high-quality products. One of the most reliable and widely used methods to evaluate this behavior is the Melt Flow Index (MFI) Test, as outlined by ASTM D1238. This standard provides a structured approach to measuring the flow rate of thermoplastic materials in a molten state, offering valuable insights into a material's properties.

What is the Melt Flow Index Test?

The Melt Flow Index (MFI) is a measurement of how easily a thermoplastic polymer can flow when subjected to heat and pressure. The test determines how much of the polymer extrudes through a small die over a set period, typically 10 minutes, under specific temperature and load conditions. The result is expressed in grams per 10 minutes, providing a numerical value to describe the material’s viscosity in its molten form.

Why is MFI Testing Important?

Understanding a polymer’s MFI is vital for manufacturers for several reasons:

- Processing Consistency: Different polymers and even batches of the same material can vary in their melt flow characteristics. Knowing the MFI helps ensure that materials behave consistently during processing, reducing variability in the final product.

- Material Selection: The MFI value plays a crucial role in selecting materials for specific applications. For example, a high MFI polymer is ideal for thin-walled products requiring fast-flowing materials, while low MFI materials are often chosen for structural applications where higher strength is needed.

- Quality Control: Regular MFI testing ensures that materials meet specific standards and performance requirements. Any deviation from expected MFI values can indicate changes in material composition, potential contamination, or degradation.

- Cost Efficiency: By optimizing processing parameters based on MFI data, manufacturers can reduce waste, lower energy consumption, and improve production efficiency.

How is the MFI Test Performed According to ASTM D1238?

The ASTM D1238 standard provides detailed procedures to ensure accuracy and repeatability in the MFI test. Here’s an overview of the key steps involved:

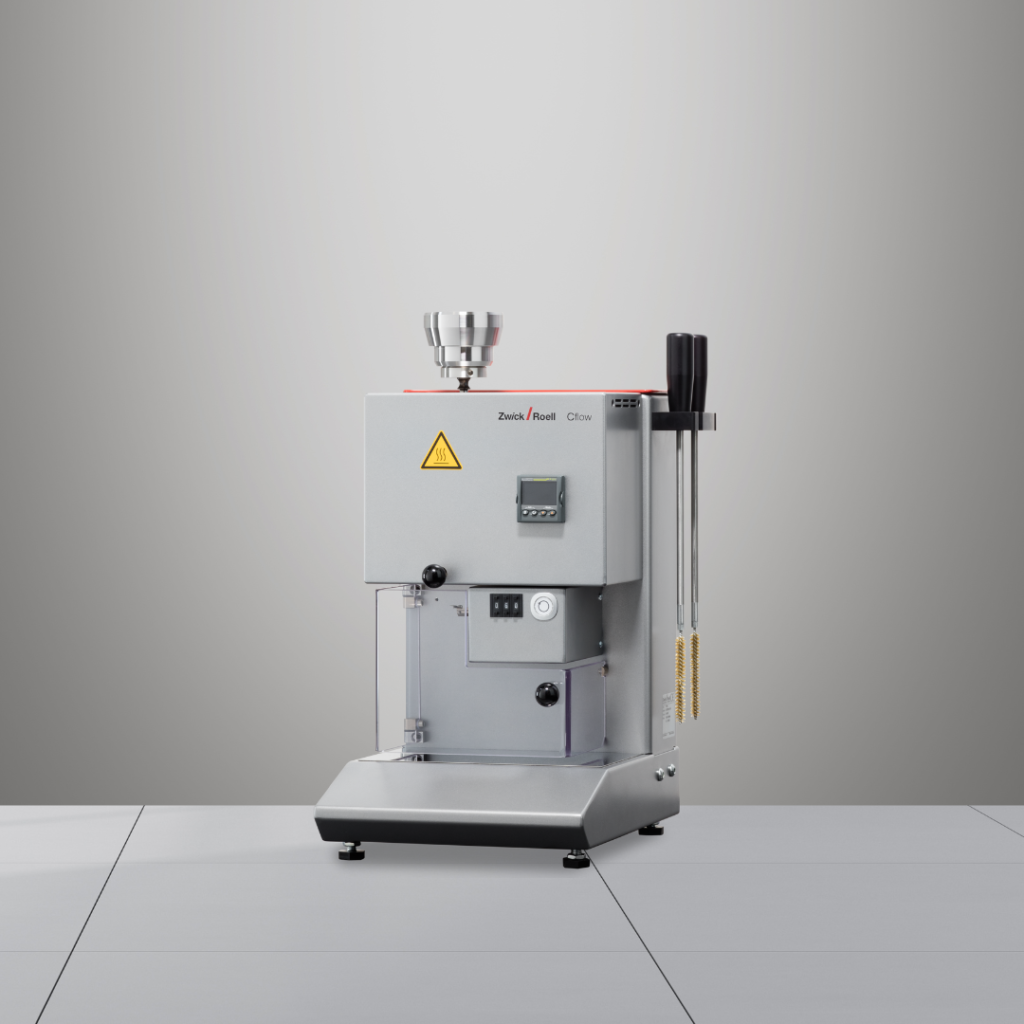

- Specimen Preparation: A sample of the thermoplastic material is heated in a precisely controlled chamber to the appropriate temperature for the material type.

- Application of Force: A standard weight (often between 2.16 kg and 21.6 kg, depending on the polymer) is applied to the material, pushing it through a die with a fixed diameter.

- Measurement: The molten material is extruded through the die over a specific period (typically 10 minutes), and the mass of material extruded is recorded. This mass is then converted to the MFI value, expressed in grams per 10 minutes.

This simple yet effective test offers critical information on the flow characteristics of the polymer, making it an indispensable tool in plastic material evaluation.

Practical Applications of MFI Data

The results of MFI testing have far-reaching implications in plastic manufacturing, including:

Injection Molding: In this process, the material’s MFI must be carefully controlled to ensure the polymer fills molds efficiently and evenly. Materials with a high MFI are better suited for producing complex, thin-walled components, while lower MFI materials are ideal for thicker, more robust parts.

Extrusion: The MFI value helps adjust process parameters like extrusion speed and temperature, allowing manufacturers to fine-tune the production of films, pipes, and other continuous products.

Blown Film Production: In film blowing applications, polymers with the correct MFI are essential to achieve the desired thickness and clarity without defects.

Trust Kiyo R&D Center for Comprehensive MFI Testing

- At Kiyo R&D Center, we understand the importance of precise and reliable material testing. Our laboratory offers Melt Flow Index testing in strict adherence to ASTM D1238. With advanced equipment and experienced technicians, we deliver accurate MFI data to support your material selection, quality control, and process optimization efforts.