Accelerated Weathering Test As Per ASTM D4364

Protecting Products from Environmental Degradation: The Role of ASTM D4364 Accelerated Weathering Test

Introduction

- Outdoor exposure can be one of the harshest environments for materials, with factors like ultraviolet (UV) radiation, moisture, and fluctuating temperatures constantly at play. To ensure products can withstand these environmental challenges, the Accelerated Weathering Test as per ASTM D4364 provides a valuable method for predicting how materials will hold up over time. This standard test simulates long-term exposure to these elements in a condensed period, allowing manufacturers to assess durability and performance before their products even hit the market.

What is the ASTM D4364 Accelerated Weathering Test?

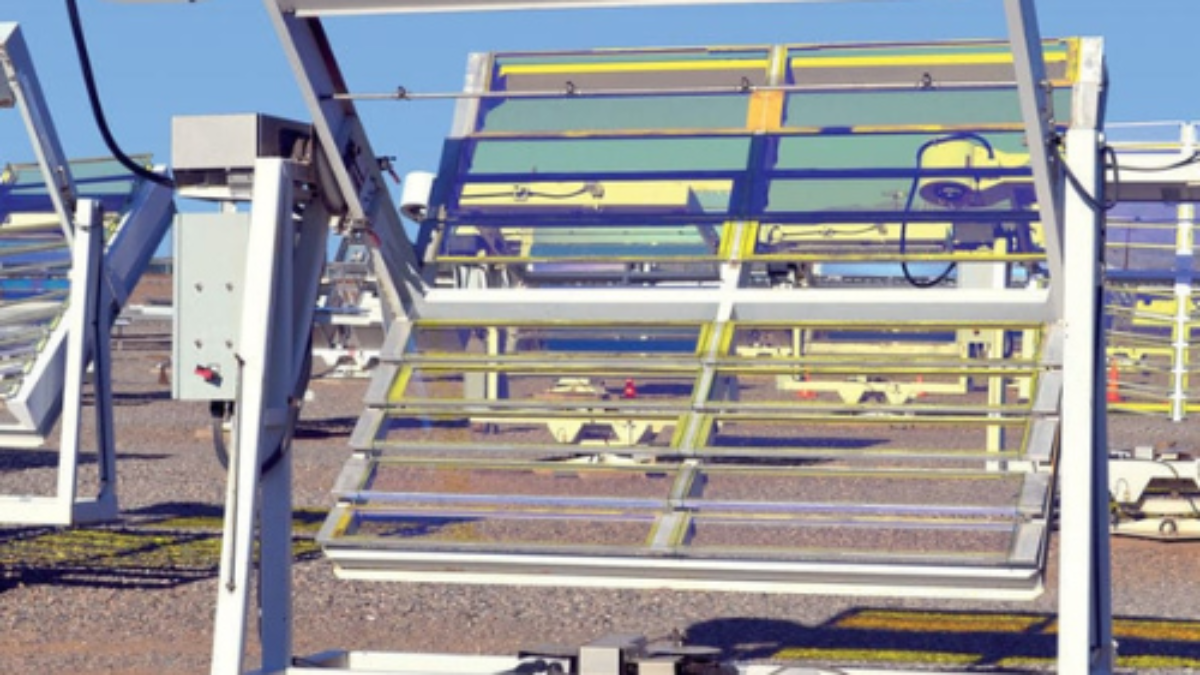

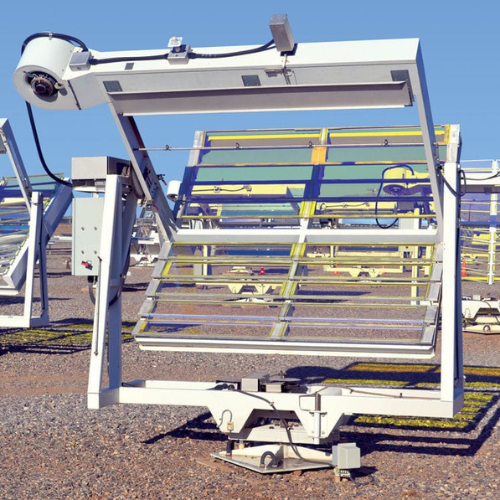

The ASTM D4364 test is a controlled laboratory procedure that mimics outdoor environmental conditions to measure the degradation of nonmetallic materials, particularly plastics and coatings, under UV light exposure, temperature extremes, and moisture. The accelerated test environment is designed to reproduce the combined effects of sunlight (UV), rain, and dew at a faster rate, giving a snapshot of how a material will perform over years of outdoor exposure in just weeks or months.

Why is Weathering Testing Important?

Materials exposed to outdoor conditions can deteriorate due to the complex interactions between UV light, moisture, and heat. Over time, these factors can lead to cracking, fading, embrittlement, or even complete failure of products. For industries such as automotive, construction, and consumer goods, where products are expected to last for years under these harsh conditions, ensuring durability is critical. By conducting weathering tests, manufacturers can identify potential weaknesses in materials, adjust formulations, and enhance product longevity.

How Does the Test Work?

The test involves placing material samples in a specialized chamber where they undergo cycles of UV radiation, condensation, and temperature changes to replicate outdoor weathering conditions. The main components of the test include:

- UV Light Exposure: UV radiation is the primary cause of material degradation in outdoor environments. UV lamps in the test chamber emit wavelengths similar to natural sunlight, accelerating the photodegradation process that can cause materials to fade, lose strength, or crack.

- Moisture and Condensation: By introducing moisture cycles through water spray or condensation, the test mimics the effects of rain and dew. These moisture cycles can contribute to surface deterioration, weakening the material over time.

- Temperature Variations: Controlled temperature cycles simulate the thermal stresses materials endure during day-night cycles and seasonal changes, helping identify temperature-induced cracking, warping, or other thermal damage.

The accelerated nature of this test allows manufacturers to observe potential long-term effects, such as discoloration, loss of flexibility, surface chalking, and cracking, in a fraction of the time required for natural weathering.

Applications of ASTM D4364 Testing

The ASTM D4364 test is widely applicable across various industries that use plastic or polymer-based products exposed to outdoor environments. Some key applications include:

- Automotive and Transportation: Exterior parts such as trim, bumpers, and mirror housings undergo significant exposure to sunlight and moisture. Testing these components ensures they retain color, strength, and performance over time.

- Building Materials: Roofing materials, siding, windows, and paints all experience constant weather exposure. ASTM D4364 helps manufacturers assess how these materials will hold up against UV damage, thermal cycling, and moisture, ensuring the longevity of buildings and infrastructure.

- Consumer Goods: Outdoor furniture, playground equipment, and sporting goods are exposed to the elements, requiring enhanced durability. Weathering tests help improve product lifespans and reduce the likelihood of material failure.

- Coatings and Paints: UV exposure can cause coatings to fade or lose adhesion, while temperature changes and moisture can cause blistering and peeling. ASTM D4364 testing ensures that these coatings meet durability standards and maintain aesthetic and protective properties over time.

Benefits of Accelerated Weathering Testing

Faster Time-to-Market: Since the test condenses years of outdoor exposure into weeks, manufacturers can identify and address potential weaknesses early in the product development phase, speeding up time-to-market.

Improved Product Performance: By understanding how materials degrade over time, manufacturers can optimize formulations to enhance UV resistance, moisture protection, and thermal stability.

Cost Savings: Early detection of potential material failures can lead to more efficient product designs and materials, reducing warranty claims, product recalls, and long-term maintenance costs.

Customer Satisfaction: Products that maintain their appearance, strength, and functionality over time lead to greater customer satisfaction and fewer returns due to premature failure.

Post-Test Analysis

After completing the weathering cycles, materials are carefully inspected for signs of degradation. Common evaluations include:

- Visual Inspection: Identifying color changes, surface cracking, and gloss loss.

- Physical Property Testing: Assessing changes in tensile strength, elongation, and impact resistance.

- Microscopic Examination: Analyzing surface structure changes and microscopic cracks that may lead to future failures.

These results provide critical data on the material’s long-term performance and offer manufacturers insights into how to improve material formulations and designs.

Conclusion

- The ASTM D4364 Accelerated Weathering Test is a vital tool for predicting the outdoor durability of materials. By simulating years of weather exposure in a controlled lab environment, manufacturers gain invaluable insights into material behavior, ensuring that their products can withstand the rigors of real-world conditions. For industries ranging from automotive to construction, this testing method plays a crucial role in enhancing product longevity, reducing failure rates, and ensuring customer satisfaction.