Friction Coefficient Testing As Per ASTM D1894

Unlocking the Importance of Friction Coefficient Testing with ASTM D1894

Introduction

- In the world of materials testing, friction plays a key role in determining how materials behave during use, especially when it comes to plastic films and sheeting. Whether it’s packaging, conveyor belts, or surface coverings, the friction between materials can greatly affect performance. To ensure reliability and performance, manufacturers and engineers rely on friction coefficient testing, particularly following ASTM D1894 standards, to accurately measure how plastic films and sheeting perform in terms of static and kinetic friction.

What is Friction Coefficient Testing as per ASTM D1894?

ASTM D1894 provides a standardized method for determining the static and kinetic coefficients of friction (COF) between plastic film or sheeting and other surfaces. It is used to assess how much resistance one material faces when it starts to move (static COF) and continues to move (kinetic COF) against another. These properties are vital for industries where products need to move or slide smoothly without sticking or causing interruptions in processes like packaging, material handling, or automated systems.

Why Do You Need Friction Coefficient Testing?

- Optimize Material Performance: Understanding how easily your material will slide against another surface is crucial in applications like packaging and shipping. A material with a high COF might stick or bunch up, whereas a material with a lower COF might move too freely, affecting stability.

- Preventing Operational Issues: For industries that rely on machinery to move products, such as the food packaging or automotive sector, precise COF measurements ensure that materials won’t cause blockages or malfunctions.

- Improving Product Design: Whether you are designing packaging films or plastic sheeting for protective purposes, knowing the COF can help you fine-tune material properties for better user experience and product performance.

How Does the ASTM D1894 Test Work?

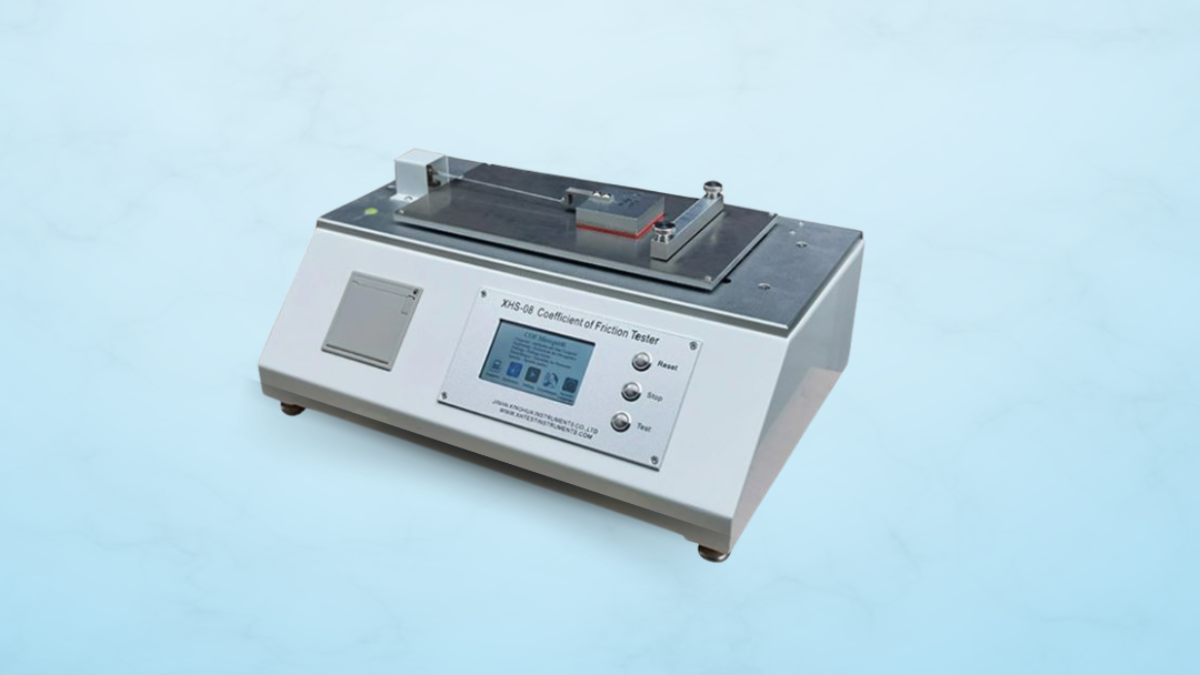

- Sample and Sled Setup: The test involves placing a sample of plastic film or sheeting on a testing surface. A sled with a known weight is then placed on top of the sample to apply a controlled load.

- Testing Process: A motorized device pulls the sled across the surface at a constant speed. The force needed to start the movement of the sled (static friction) and the force needed to keep it moving (kinetic friction) are measured.

- Calculating Results: These forces are used to calculate the static and kinetic coefficients of friction, giving insight into how much resistance the material faces when interacting with other surfaces.

Real-World Applications of Friction Coefficient Testing

Packaging Films: Manufacturers use ASTM D1894 testing to ensure their plastic films have the right friction properties to function efficiently in automated packaging lines. Too much friction can cause jams, while too little can result in the films sliding out of place.

Conveyor Belts and Material Handling: In operations that rely on conveyor belts, knowing the friction between the belt material and the transported goods is essential for smooth and uninterrupted movement.

Textiles and Apparel: When fabrics are treated with plastic sheeting or films, friction testing can determine how comfortably and effectively these materials interact during use, ensuring they meet quality standards.

Benefits of Conducting Friction Coefficient Testing

- Product Safety: Testing ensures that materials used in consumer products have the correct balance of friction to prevent slippage or unwanted movement during use.

- Process Efficiency: With accurate friction data, manufacturers can optimize processes, reduce downtime due to material handling issues, and improve operational efficiency.

- Enhanced Material Design: Engineers can design materials with specific friction characteristics tailored to their application, improving overall product quality and functionality.

Kiyo R&D Center: Your Partner for ASTM D1894 Testing

- At Kiyo R&D Center, we specialize in providing precise and reliable friction coefficient testing services as per ASTM D1894 standards. With advanced testing equipment and experienced technical staff, we deliver accurate data to help you make informed decisions about material performance.