Abrasion Resistance Testing As Per ASTM D4060

Understanding Abrasion Resistance: A Deep Dive into ASTM D4060 Testing

Introduction

- Abrasion Resistance Testing as per ASTM D4060: A Comprehensive Guide Abrasion resistance is a critical property for materials exposed to wear and tear during usage. Evaluating this property ensures that the material can withstand physical damage and maintain its performance over time. In this blog, we’ll explore abrasion resistance testing as per ASTM D4060, its significance, procedures, and how this testing method is implemented. For businesses and researchers in South India, we’ll also highlight options for abrasion resistance testing in Tambaram, a growing hub for advanced material testing.

What is Abrasion Resistance Testing?

Abrasion resistance testing measures a material’s ability to withstand mechanical wear caused by rubbing, scraping, or erosion. This is especially important for coatings, plastics, rubber, textiles, and metals that need to maintain their integrity under physical stress. High abrasion resistance contributes to a longer lifespan and better performance of products in demanding applications.

Significance of ASTM D4060

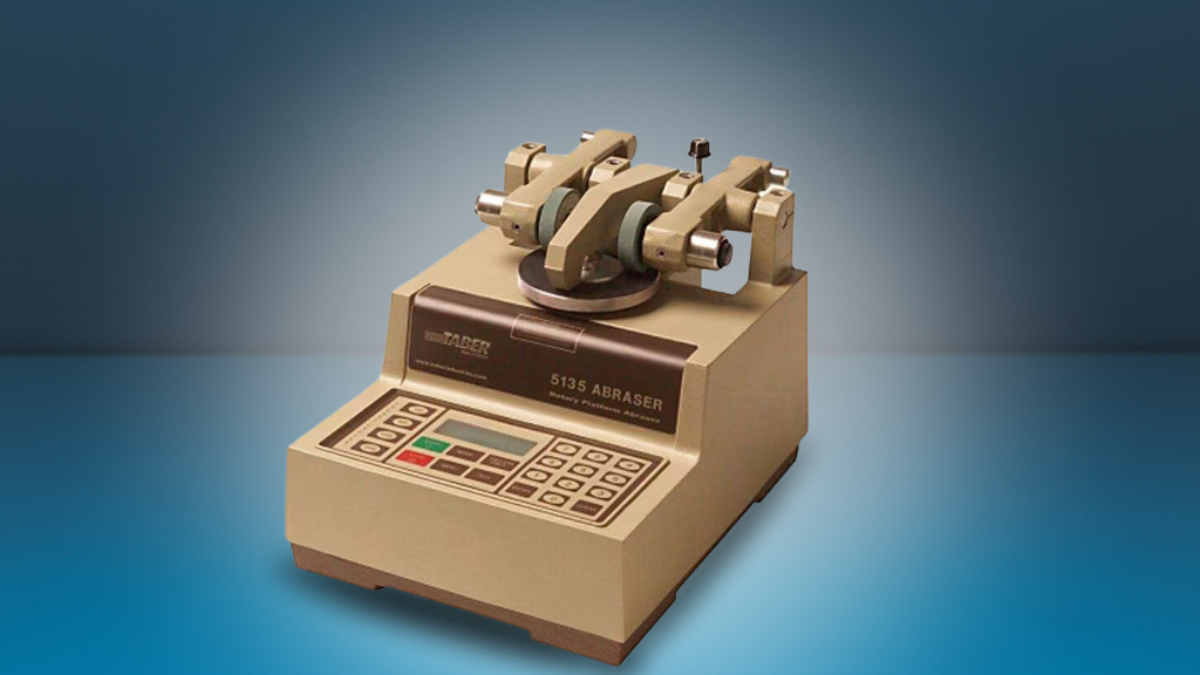

ASTM D4060 is a globally recognized standard that outlines the methodology for testing the abrasion resistance of organic coatings using a Taber Abraser. This standard is widely used because it provides a repeatable and reliable way to simulate wear in a controlled environment.

Some common industries relying on this test include:

- Automotive: Ensuring durability of interior and exterior components.

- Construction: Evaluating coatings used on concrete and steel structures.

- Textiles and Footwear: Assessing the wear resistance of fabrics and soles.

- Aerospace: Testing the durability of coatings used in critical environments.

How Does ASTM D4060 Work?

The ASTM D4060 test employs a Taber Abraser, a device specifically designed for this purpose. Here’s an outline of the procedure:

- Preparation of the Sample:

- A flat, uniform sample of the coating is mounted on the Taber Abraser platform.

Selection of Abrasive Wheels:

- The test uses abrasive wheels, typically CS-10 or H-18, depending on the material’s hardness.

Application of Load:

- A specified weight (often 500g or 1000g) is applied to simulate real-world pressure.

Abrasion Process:

- The sample is subjected to rotational abrasion for a set number of cycles. The wear is induced by the friction between the sample and the abrasive wheels.

Evaluation:

- The wear is assessed by measuring weight loss, thickness loss, or visual degradation. Results are expressed in milligrams of material lost per 1000 cycles.

Factors Influencing Results

Several factors impact the outcome of the abrasion resistance test:

- Material Composition: Harder materials generally exhibit better resistance.

- Coating Thickness: Thicker coatings tend to last longer under abrasive conditions.

- Test Parameters: Wheel type, load, and number of cycles significantly affect wear.

Applications of Abrasion Resistance Testing

This test is crucial for validating product performance across various industries:

Protective Coatings:

- Testing ensures the durability of coatings used in harsh environments, such as marine and industrial settings.

Flooring and Tiles:

- Abrasion resistance is essential for high-traffic areas to maintain aesthetics and functionality.

Packaging:

- Ensuring that printed surfaces on packaging remain legible and intact.

Consumer Goods:

- Testing products like eyewear, electronics, and furniture for long-term usability.

Abrasion Resistance Testing in Tambaram

If you are looking for reliable abrasion resistance testing in Tambaram, Kiyo R&D Center and Laboratory is a leading provider of this specialized service. Located in one of Chennai’s growing industrial areas, Tambaram has become a hub for material testing facilities offering ASTM-compliant services.

At Kiyo R&D Center And Laboratory, we utilize advanced Taber Abrasers and adhere strictly to ASTM D4060 standards. Our team ensures accurate results by customizing test parameters to meet specific material needs. Whether you’re in the automotive, aerospace, or consumer goods sector, our services in Tambaram provide unmatched expertise in abrasion resistance testing.

Why Choose Kiyo R&D for Abrasion Resistance Testing?

- State-of-the-Art Equipment: We use industry-standard Taber Abrasers for precise testing.

- Expert Team: Our technicians are well-versed in ASTM D4060 and similar protocols.

- Customized Solutions: Tailored test methods based on the application and material.

- Convenience: Our location in Tambaram ensures accessibility for clients in Chennai and nearby regions.

- Comprehensive Reports: Detailed insights to support R&D, quality control, and product certification.

Conclusion

- Abrasion resistance testing as per ASTM D4060 plays a pivotal role in determining the longevity and performance of materials subjected to wear. Understanding its methodology and significance helps industries ensure the reliability of their products. For those seeking top-tier abrasion resistance testing in Tambaram, Kiyo R&D Center is your trusted partner. Our cutting-edge facilities and commitment to quality ensure that your products meet the highest durability standards.