Flammability Property Testing As per standard ASTM E84

Understanding Flammability Property Testing as per ASTM E84

Introduction

- Fire safety is a critical concern in building materials, and one of the most widely recognized standards for assessing the fire performance of materials is ASTM E84, also known as the Standard Test Method for Surface Burning Characteristics of Building Materials. This test is essential in evaluating how materials will behave in a fire scenario, particularly how flames spread across surfaces and the amount of smoke generated during combustion. In this blog, we’ll explore the details of ASTM E84 testing, its methodology, and why it’s so vital for ensuring the safety of buildings and their occupants.

What is ASTM E84?

ASTM E84 is a fire test method designed to assess the surface burning characteristics of building materials. Often referred to as the Steiner Tunnel Test, this test measures two key factors:

- Flame Spread Index (FSI): The rate at which flames spread over the material’s surface.

- Smoke Developed Index (SDI): The amount of smoke generated during combustion.

These indices are crucial for classifying materials based on their fire performance, enabling manufacturers, engineers, and architects to make informed decisions about material selection for construction projects.

Purpose and Importance of ASTM E84 Testing

The primary goal of ASTM E84 is to ensure that materials used in construction meet the necessary fire safety standards. Many building codes and regulations require materials to undergo flammability testing as part of the approval process for use in certain applications. ASTM E84 is particularly important in assessing:

- Wall and ceiling materials used in buildings.

- Insulation materials and other surface coatings.

- Decorative elements that may be prone to fire exposure.

Materials that perform well in this test can significantly reduce the risk of fire spreading, providing valuable time for building occupants to evacuate and for firefighters to respond. This makes ASTM E84 an essential test for ensuring public safety.

Key Elements of ASTM E84 Testing

1. Test Setup and Procedure

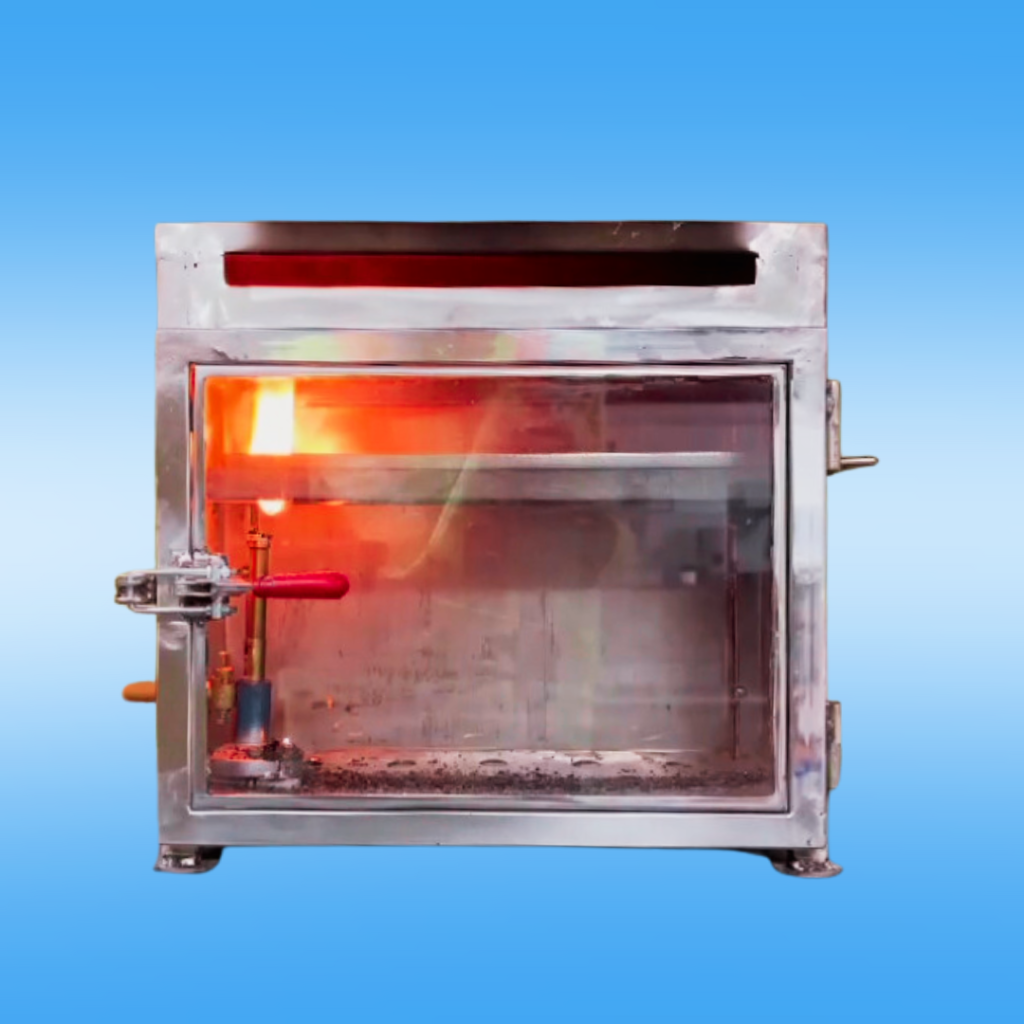

The ASTM E84 test is conducted in a 25-foot-long horizontal tunnel, with the test material mounted on the ceiling. The material is subjected to a controlled flame at one end of the tunnel, and the test is typically run for 10 minutes.

- Flame Spread Measurement: As the flames move across the surface of the material, sensors track the speed at which the flames spread, providing data for the Flame Spread Index (FSI).

- Smoke Measurement: Simultaneously, the smoke produced by the burning material is collected and measured to determine the Smoke Developed Index (SDI).

2. Interpretation of Results

The results of the ASTM E84 test provide a classification for the material, typically falling into one of three categories:

- Class A (Class I): FSI of 0 to 25, and SDI of 0 to 450. Materials in this class exhibit the highest level of fire resistance.

- Class B (Class II): FSI of 26 to 75, and SDI of 0 to 450. Materials with moderate flame spread.

- Class C (Class III): FSI of 76 to 200, and SDI of 0 to 450. Materials in this class exhibit higher flame spread but still meet minimum safety standards.

These classifications are crucial in determining where materials can be used within a building, with Class A materials often required for high-risk areas such as corridors and exits.

Why ASTM E84 is Crucial for Building Safety

Incorporating materials that meet ASTM E84 standards is critical for maintaining fire safety in commercial, residential, and industrial buildings. The results from this test influence:

- Building Code Compliance: Many regions require materials to meet ASTM E84 classifications, especially for materials used in escape routes or high-occupancy areas.

- Product Development and Innovation: Manufacturers often rely on ASTM E84 testing to certify new materials, especially those that use innovative compositions like composites, synthetic fabrics, or treated woods.

- Risk Mitigation: By ensuring that materials resist flame spread and limit smoke production, building designs can significantly lower the risk of catastrophic fire events.

ASTM E84 and Modern Materials

As construction materials evolve, so does the application of ASTM E84 testing. Traditional materials like wood, metal, and gypsum board are still widely tested, but newer materials such as composites, foams, and coatings are increasingly subjected to ASTM E84 to ensure they meet the same fire safety standards.

For instance, insulating materials made from synthetic or eco-friendly compounds often undergo ASTM E84 testing to ensure that they do not pose an increased fire hazard despite their environmental benefits. The ability to certify these materials as safe for use in buildings allows the construction industry to innovate without compromising on safety.

Conclusion

- ASTM E84 is a cornerstone of fire safety testing, providing critical insights into how materials will behave in a fire. By measuring flame spread and smoke production, this test ensures that building materials meet the stringent safety standards necessary for protecting occupants in the event of a fire.