Flexural/Modules Testing as per ASTM D790

Understanding Flexural Modulus Testing: A Critical Evaluation for Material Performance

Introduction

- Flexural modulus testing is an essential method in the field of material science, particularly when assessing the stiffness and performance of materials under bending conditions. Flexural modulus, often referred to as the "modulus of elasticity in bending," provides critical data on how a material will respond when subjected to a flexural load. The ASTM D790 standard is widely recognized for governing the procedures to determine these properties, making it a key reference in industries such as plastics, composites, and metals.

Why Flexural Modulus Matters Flexural modulus is a measure of a material’s stiffness when it is bent, providing insights into its resistance to deformation under load. This property is particularly important for applications where materials must maintain their shape under bending forces, such as in beams, structural components, and mechanical parts. Understanding the flexural modulus helps engineers and designers ensure that a material can withstand operational stresses without excessive bending or failure.

ASTM D790: The Gold Standard The ASTM D790 standard outlines the methodology for determining the flexural properties of both unreinforced and reinforced plastics. This standard is crucial for evaluating materials that will be subjected to bending stresses, offering a consistent and reliable means to measure and compare different materials.

Test Specimen Preparation

The preparation of test specimens according to ASTM D790 is critical to obtaining accurate and repeatable results. The standard specifies that specimens must be rectangular in shape with uniform dimensions, typically 127 mm in length, 12.7 mm in width, and 3.2 mm in thickness. These dimensions may vary depending on the specific material and its intended application.

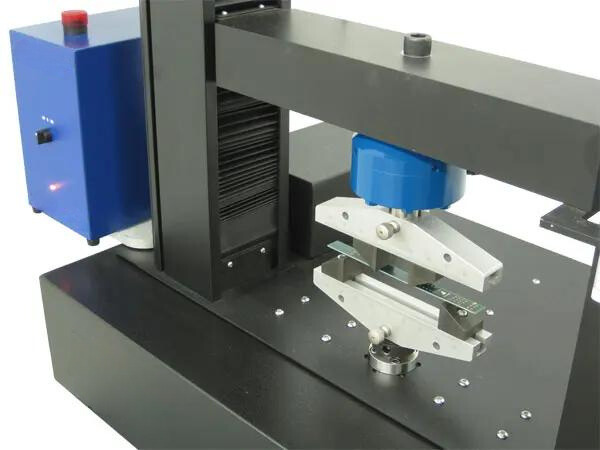

Testing Equipment and Setup

Flexural modulus testing requires a universal testing machine equipped with a flexural fixture. The specimen is supported on two points, with the load applied at the midpoint by a loading nose. The span between the supports and the speed at which the load is applied are carefully controlled to ensure that the test conditions match those outlined in ASTM D790.

Conducting the Test

- Conditioning the Specimens: Before testing, specimens must be conditioned to ensure that the results are not affected by environmental factors such as temperature or humidity. ASTM D618 provides the standard procedures for conditioning plastic specimens, which must be followed closely.

- Testing Procedure: The flexural modulus test is performed by applying a load at the midpoint of the specimen at a constant rate. The load and the corresponding deflection of the specimen are recorded until the specimen fails or the maximum strain is reached.

- Calculating Flexural Modulus: Flexural modulus is calculated from the initial slope of the load-deflection curve obtained during testing. This slope represents the ratio of stress to strain in the elastic region of the material’s deformation, providing a measure of the material’s stiffness under bending.

Interpretation of Results

The flexural modulus data obtained from ASTM D790 testing offers invaluable information for material selection and design. High flexural modulus indicates that a material is stiff and will not bend easily under load, making it suitable for structural applications where rigidity is crucial. Conversely, a lower flexural modulus may be desirable in applications where flexibility and ductility are more important.

Applications of Flexural Modulus Testing

Flexural modulus testing is widely used in various industries to ensure the materials used in products can meet specific performance requirements. Some key applications include:

- Automotive: In the automotive industry, flexural modulus is critical for components like dashboards, door panels, and exterior trims, which need to be both durable and flexible.

- Construction: In construction, materials with high flexural modulus are essential for beams, panels, and structural supports that must withstand heavy loads without bending.

- Aerospace: Aerospace applications require materials that combine light weight with high stiffness to ensure structural integrity under high stress conditions.

Conclusion

- Flexural modulus testing as per ASTM D790 is a vital tool in the evaluation of material performance, particularly for applications where bending stresses are a concern. By providing a reliable measure of material stiffness, this testing method helps engineers and designers select the appropriate materials for their projects, ensuring that the final products are both safe and effective. Understanding the principles and procedures behind flexural modulus testing allows for better material selection, design optimization, and quality control in a wide range of industries.