Many companies assume that if a material looks strong or has passed previous batches, it will perform the same in production. That assumption is risky.

Small variations in raw material composition, processing conditions, or storage environment can change material strength significantly.

Using ultimate tensile stress test services in chennai – Kiyo R&D LAB helps industries:

Verify material strength before production

Compare different materials objectively

Confirm supplier specifications

Detect weak batches early

Prevent product failure in service

Improve product design reliability

Meet technical and regulatory requirements

Without tensile testing, manufacturers are making decisions based on assumptions rather than measurable data.

Ultimate tensile stress is the maximum stress a material can withstand before breaking when stretched.

It represents the peak point on a stress-strain curve where the material reaches its highest load-bearing capacity.

In simple terms:

Higher UTS → stronger material

Lower UTS → weaker material

Knowing this value helps engineers determine whether a material is suitable for structural, mechanical, or load-bearing applications.

This is why manufacturers rely on ultimate tensile stress test services in chennai – Kiyo R&D LAB to validate material performance before product development or supply.

Ultimate tensile testing follows a controlled laboratory procedure:

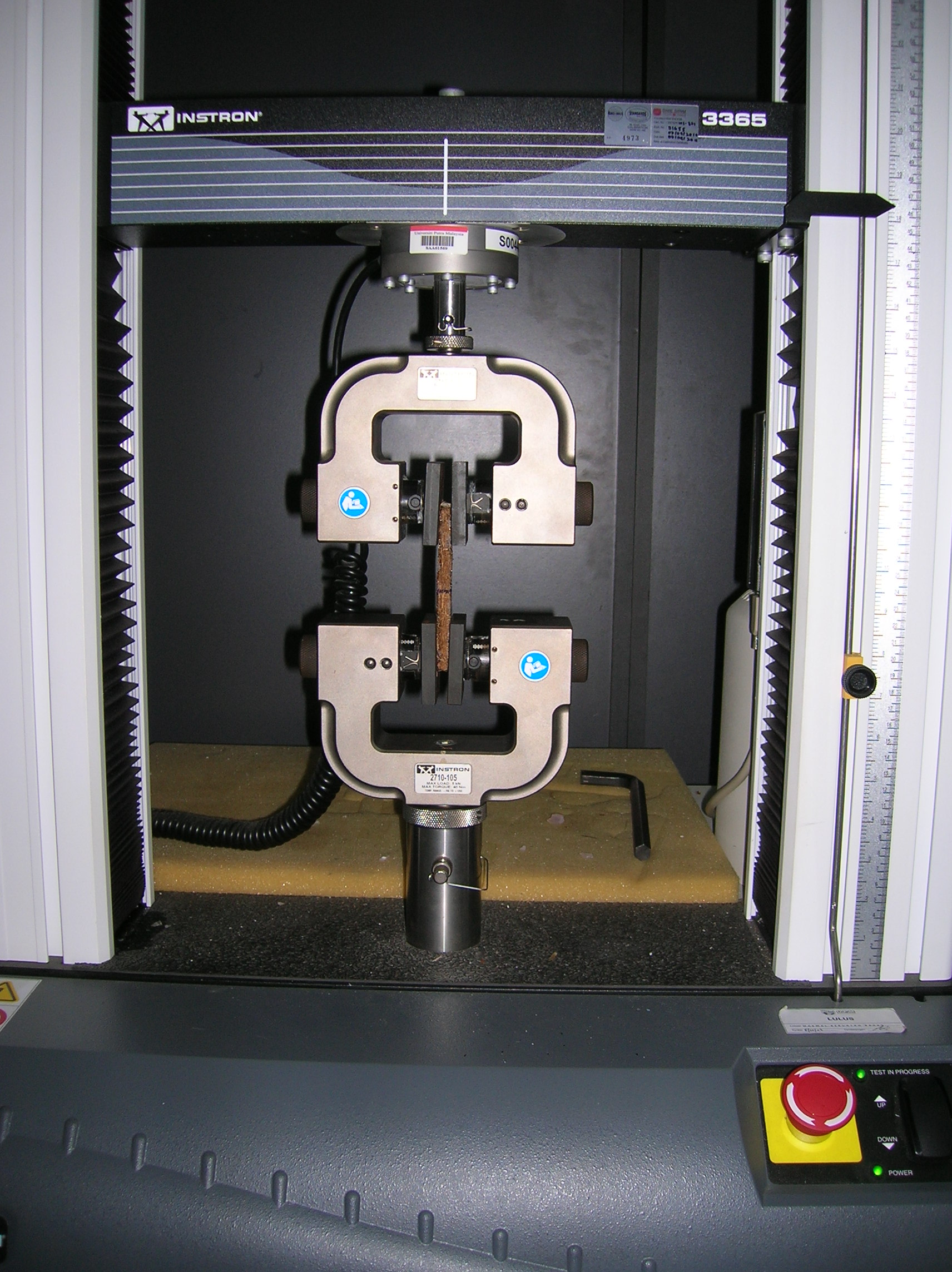

A sample specimen is prepared according to standard dimensions.

The specimen is placed in a universal testing machine.

A tensile load is applied gradually.

The machine records load and elongation.

The maximum stress before fracture is calculated as UTS.

The test provides a full stress-strain profile, which gives deeper insights into material behavior beyond just strength.

Ultimate tensile stress test services in chennai – Kiyo R&D LAB are applicable to a wide range of materials:

Plastics and polymers

Rubber materials

Metals and alloys

Composite materials

Films and sheets

Textiles and fibers

Adhesives and bonded joints

If your product must withstand pulling forces or tension during use, tensile testing is essential.

Kiyo R&D LAB performs tensile testing according to recognized national and international standards, including:

ASTM tensile testing standards

ISO mechanical testing standards

IS standards where applicable

Customer or project-specific specifications

This ensures that reports generated through ultimate tensile stress test services in chennai – Kiyo R&D LAB are accepted for audits, approvals, product validation, and technical documentation.

You should use ultimate tensile stress test services in chennai – Kiyo R&D LAB if you operate in:

Plastic parts, molded components, metal structures, and engineering products.

Load-bearing components, seals, fasteners, interior parts, structural elements.

Geotextiles, reinforcement materials, polymers, and structural components.

Films, laminates, straps, and flexible materials.

Material development, comparative studies, failure analysis.

If your product performance depends on strength, UTS testing is critical.

Chennai is a major industrial hub with strong manufacturing, automotive, plastics, and engineering sectors. Local companies need reliable testing services that provide accurate data quickly.

That is why organizations searching for ultimate tensile stress test services in chennai – Kiyo R&D LAB choose a laboratory that offers:

Standard-based testing procedures

Calibrated instruments

Accurate measurements

Fast turnaround time

Clear technical reports

Professional testing support

Reliable testing helps engineers make confident decisions about materials and product performance.

Skipping tensile testing may appear to save cost, but it often leads to much larger losses later.

Without testing, companies risk:

Product failure

Structural defects

Warranty claims

Customer complaints

Production rework

Safety incidents

Using ultimate tensile stress test services in chennai – Kiyo R&D LAB helps identify weak materials before they reach production or the market.

Testing is always cheaper than failure.

Routine tensile testing can reveal hidden issues such as:

Poor raw material quality

Improper processing conditions

Material degradation

Weak bonding or adhesion

Incorrect formulation

Batch inconsistency

Without proper testing, these issues may only become visible after product failure.

Many companies test materials only after a failure occurs. That reactive approach wastes time, money, and reputation.

Smart manufacturers who use ultimate tensile stress test services in chennai – Kiyo R&D LAB test materials before production begins. This proactive approach ensures reliable performance and consistent quality.

For quotation or visit