When a product bends, it reveals the truth about its strength. Whether it’s a plastic profile, a composite panel, a 3D-printed component, a rubber part, or any structural material, bending forces determine how long it will last and how safely it will perform. That’s exactly why flexural testing laboratory services – Kiyo R&D LAB have become essential for manufacturers, OEMs, R&D teams, and engineering students across India.

Flexural testing is one of the most important mechanical tests used to assess the stiffness, durability, and load-bearing capability of materials. From advanced engineering plastics to composites and construction materials, flexural testing provides insights no other test can offer. At Kiyo R&D Lab, a NABL-accredited testing facility in Chennai, these tests are performed with high accuracy using globally recognized standards such as ASTM D790 and ISO 178.

This blog explains what flexural testing is, why it matters, the industries that depend on it, and how Kiyo R&D LAB delivers accurate, reliable, and fast results for real-world applications.

Flexural testing determines how a material behaves when subjected to bending. Unlike tensile or compression tests, flexural testing applies a combination of tension on one side and compression on the other, revealing the true bending performance of a material.

This test helps determine:

Why is this important?

Because products rarely face just pulling or pushing forces in real life. They bend, twist, flex, and absorb dynamic loads — and poor flexural performance leads to cracking, warping, deformation, and catastrophic failures.

This is why industries heavily depend on flexural testing laboratory services – Kiyo R&D LAB to ensure their materials can withstand real-world bending forces.

Flexural properties decide the safety and durability of many products, especially those used for load-bearing or structural applications. Some common use cases include:

Materials like polycarbonate, nylon, ABS, PBT, HDPE, and polypropylene must meet flexural standards for:

Used in:

Flexural testing ensures these products don’t deform or break under bending stress.

FRP, carbon fiber, fiberglass, and sandwich composites rely heavily on flexural data for:

Rubber materials must show flexibility and resilience without cracking under repeated bending.

Thermoformed trays, printed packaging, sheets, and foils require flexural stiffness for performance.

Additive manufacturing materials must be tested to ensure reliability under bending.

Boards, panels, WPC, ACP sheets, and insulation materials use flexural testing for load-bearing capability.

No matter the industry, flexural testing is a key quality checkpoint — and Kiyo R&D Lab provides the certification, data, and accuracy needed for compliance.

Kiyo R&D Lab performs flexural tests strictly according to globally recognized standards:

Used for rigid and semi-rigid plastics. Provides:

Similar to ASTM but with slight variations in test speed and sample dimensions.

The use of proper standards ensures all reports are valid for audits, certifications, and industrial compliance.

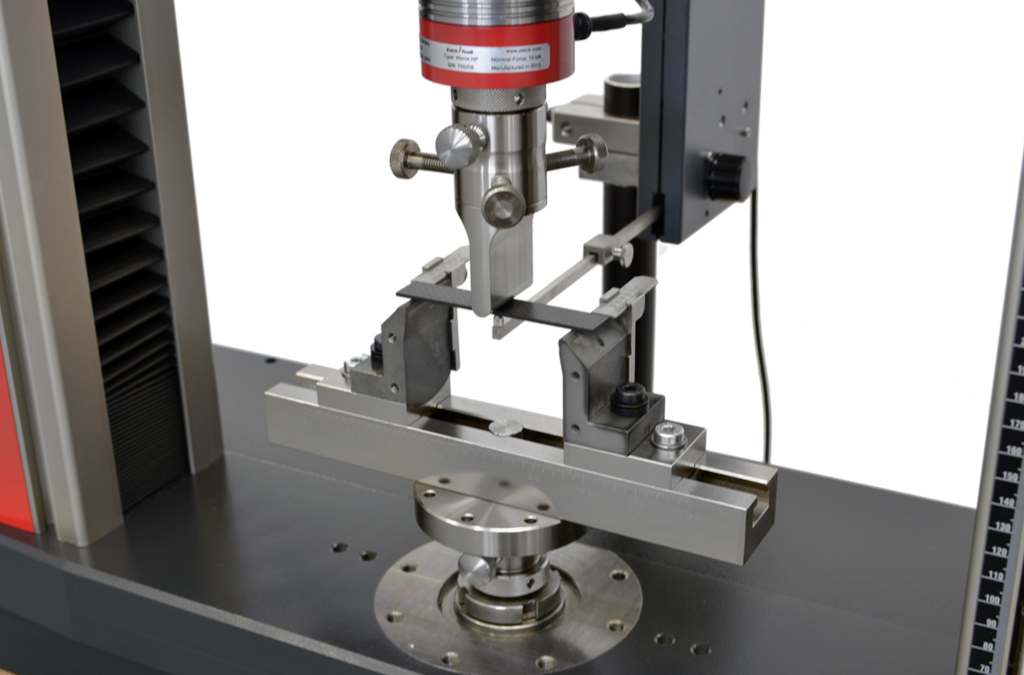

Flexural testing is performed using a Universal Testing Machine (UTM) equipped with a 3-point or 4-point bending fixture.

The material is cut to exact dimensions specified by the standard.

The UTM applies bending force gradually while recording:

The machine automatically generates:

Kiyo R&D Lab provides detailed, traceable, NABL-compliant reports.

Manufacturers choose flexural testing laboratory services – Kiyo R&D LAB because bending performance determines:

Machines, molds, material grades, and production processes all impact flexural properties. Testing helps detect:

Flexural testing is not “optional”—it is a core requirement for quality assurance.

Kiyo R&D Lab has earned trust across South India due to its:

Test reports are globally accepted and audit-ready.

UTM with bending fixtures calibrated for accuracy.

Most reports delivered within 1 business day.

Plastics, composites, rubber, polymers, laminates, WPC, ACP, 3D printed materials, and more.

Affordable pricing plus clear report explanation.

All tests follow international protocols.

Used by leading industries and engineering institutions.

Customers use the results from flexural testing laboratory services – Kiyo R&D LAB for:

Strong flexural data = stronger products.

Flexural testing is one of the most revealing mechanical tests for any material used in load-bearing or structural applications. Whether you’re working with plastics, composites, rubber, PVC, or 3D printed parts, bending strength determines how well your product performs in the real world.

With advanced equipment, NABL accreditation, and rapid reporting, flexural testing laboratory services – Kiyo R&D LAB offer manufacturers and students reliable, accurate, and audit-ready mechanical data.

If your product bends, flexes, supports weight, or faces real-world mechanical stress, flexural testing is not optional — it’s essential.