Analysis TGA Services in Chennai – Kiyo R&D Lab

Every material tells a story when exposed to heat. Some hold their shape, some crumble, and others transform into something new. Understanding this behavior is at the heart of Thermogravimetric Analysis (TGA). At Kiyo R&D Lab, we offer professional and precise Analysis TGA Services in India to help industries, researchers, and students decode material behavior under temperature variations.

Thermal Precision Redefined: Analysis TGA Services in India – Kiyo R&D Lab

Thermogravimetric Analysis, or TGA, is a method used to measure how a material’s weight changes as it is heated over time. This data helps determine the sample’s composition, thermal stability, and the temperatures at which it undergoes physical or chemical transformations.

In simpler terms, TGA reveals how strong, stable, or pure a material is when it faces heat—making it one of the most vital techniques in material testing.

Key parameters analyzed during TGA include:

• Weight loss due to decomposition or evaporation.

• Decomposition temperature and stability range.

• Percentage of fillers, ash, or residue after heating.

• Moisture or volatile content in materials.

In industries like plastics, rubber, coatings, and composites, temperature plays a huge role in determining product performance. A polymer that breaks down at 150°C might fail in an automotive environment, while a thermally stable coating could resist degradation even beyond 300°C. Through Analysis TGA Services in India – Kiyo R&D Lab, we help you identify these critical temperature points with accuracy and confidence.

Our clients use TGA data to improve product formulations, validate material suppliers, and ensure consistent quality in manufacturing. It’s also a key part of research and development, helping scientists optimize blends, additives, and heat treatments for better performance.

Kiyo R&D Laboratory in Chennai is equipped with advanced Thermogravimetric Analysis systems that ensure high precision, reliability, and reproducibility. Our NABL-accredited testing procedures are performed by skilled technicians who understand the science behind every reading.

Highlights of our TGA facility:

• Temperature range: Ambient to 1000°C.

• Controlled heating rate: 2°C/min to 20°C/min for flexible applications.

• High-sensitivity balance for micro-level mass changes.

• Option for inert or oxidative atmosphere (Nitrogen/Air).

• Fully digital analysis with real-time data acquisition and plotting.

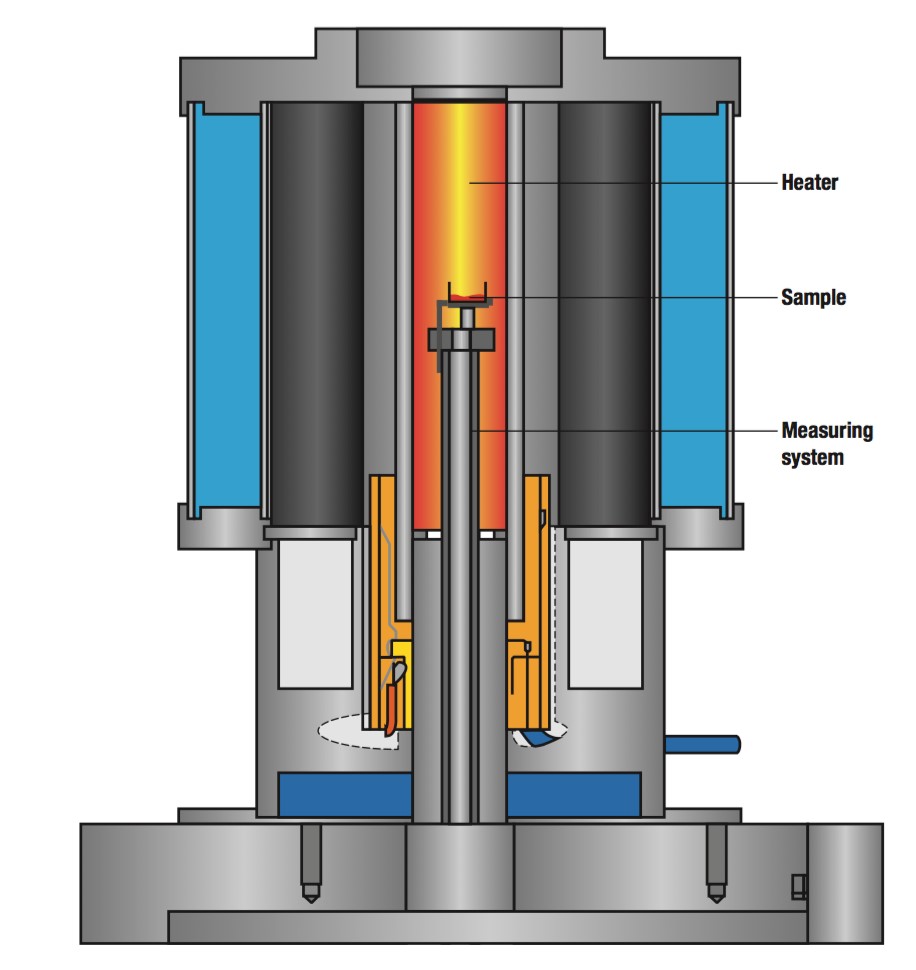

The TGA process at Kiyo R&D Lab is carefully structured to ensure every step meets international testing standards such as ASTM and ISO.

Our procedure involves:

1. Sample preparation as per the required standard dimensions.

2. Placement of the sample in a precision crucible inside the furnace chamber.

3. Selection of the heating program and atmosphere (air or inert).

4. Gradual heating of the sample while monitoring its weight in real-time.

5. Recording the TGA curve (weight vs. temperature) to identify decomposition stages.

6. Data interpretation and report generation with graphical representation.

Thermogravimetric Analysis is one of the most versatile tests in materials science. Our Analysis TGA Services in India cater to multiple sectors, providing valuable data for process improvement and product validation.

Common applications include:

• Determining filler and ash content in plastics or rubber compounds.

• Evaluating thermal stability of coatings and paints.

• Studying polymer degradation and oxidation behavior.

• Analyzing moisture and volatile content in raw materials.

• Characterizing composite materials and adhesives.

Choosing the right laboratory makes all the difference. With years of experience and cutting-edge equipment, Kiyo R&D Lab ensures you get actionable insights backed by precision and professionalism.

Here’s why our clients trust us:

• NABL-accredited testing with international credibility.

• Fast and reliable results within 1–2 working days.

• Expert interpretation and technical consultation.

• Cost-effective testing packages for industries and students.

• Transparent reports with clear graphs and findings.

The TGA curve provides a visual representation of how your sample reacts to heat. Each weight loss step represents a physical or chemical change.

Typical stages observed:

• Stage 1: Evaporation of moisture or solvents (below 150°C).

• Stage 2: Decomposition of organic components (200–500°C).

• Stage 3: Residue or filler left behind (above 600°C).

This analysis helps you identify not only the composition but also the quality of the material’s formulation, stability, and resistance to heat.

Our Analysis TGA Services in India are used by a wide range of sectors, including:

• Automotive and Aerospace – for material validation and safety testing.

• Polymer and Rubber Manufacturing – for formulation optimization.

• Paints and Coatings – for binder and solvent studies.

• Chemical and Composite Industries – for research and process improvement.

• Academic and Research Institutions – for student and R&D projects.

At Kiyo R&D Lab, we believe that accurate testing leads to confident decisions. Our mission is to provide reliable data that strengthens your designs, validates your products, and enhances your reputation. We work closely with clients to deliver customized analysis and continuous support.

Discover the difference that precision can make. Partner with Kiyo R&D Lab for professional Analysis TGA Services in India and unlock deeper insights into your material’s thermal performance. From plastics to paints, we help you ensure your products stand strong under every degree of heat.