TGA Analysis of Polymers in Chennai – Kiyo R&D LAB: Decomposition, Ash & Volatiles

Most polymer failures don’t start with cracks or visible damage. They start silently—inside the material—when heat, time, or environment slowly break down the polymer structure. By the time a part discolors, smells, or loses strength, degradation has already progressed too far.

This is exactly why tga analysis of polymers in chennai – Kiyo R&D LAB plays a critical role in modern material testing.

Thermogravimetric Analysis (TGA) is not just a laboratory technique. It is a decision tool used to understand how polymers behave when exposed to heat, how stable they really are, and what they are actually made of—not what the datasheet claims.

TGA measures weight change of a material as a function of temperature or time under a controlled atmosphere. In simple terms, it tells you:

For polymers, this information is critical because thermal degradation often dictates real service life.

A polymer that looks fine at room temperature may begin degrading far below its expected operating range. TGA helps identify that risk before it becomes a field failure.

Many teams rely only on mechanical tests like tensile or impact. That’s a mistake.

Mechanical tests tell you how a polymer performs now.

TGA tells you how long it can survive under heat.

TGA analysis is essential when:

This is why tga analysis of polymers in chennai – Kiyo R&D LAB is widely used across automotive, electrical, packaging, and industrial sectors.

TGA provides insights that most other tests cannot.

TGA identifies:

This helps determine whether a polymer can safely operate at a given temperature without losing integrity.

Many polymers contain fillers such as:

TGA quantifies actual filler or ash content, which is critical for supplier validation and grade comparison.

Early weight loss in TGA curves often indicates:

These can cause issues like porosity, odor, or reduced mechanical strength.

Two polymer grades may claim identical properties, but TGA often reveals:

This makes TGA a powerful tool for material comparison and approval.

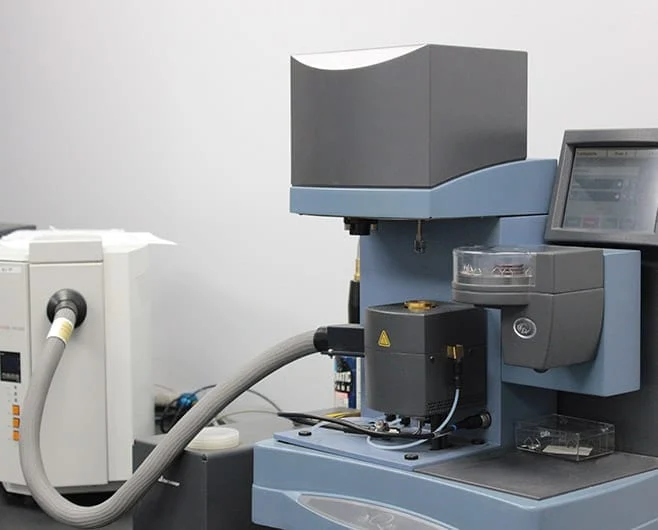

At Kiyo R&D LAB, TGA is not treated as a graph-printing exercise. The focus is on interpretation and application relevance.

The lab ensures:

Because small variations in TGA parameters can significantly affect results.

Polymer samples may be:

Small, representative samples are carefully prepared to avoid contamination or uneven heating.

Depending on the application, TGA may be performed under:

Heating rates and temperature ranges are chosen based on material type and testing objective.

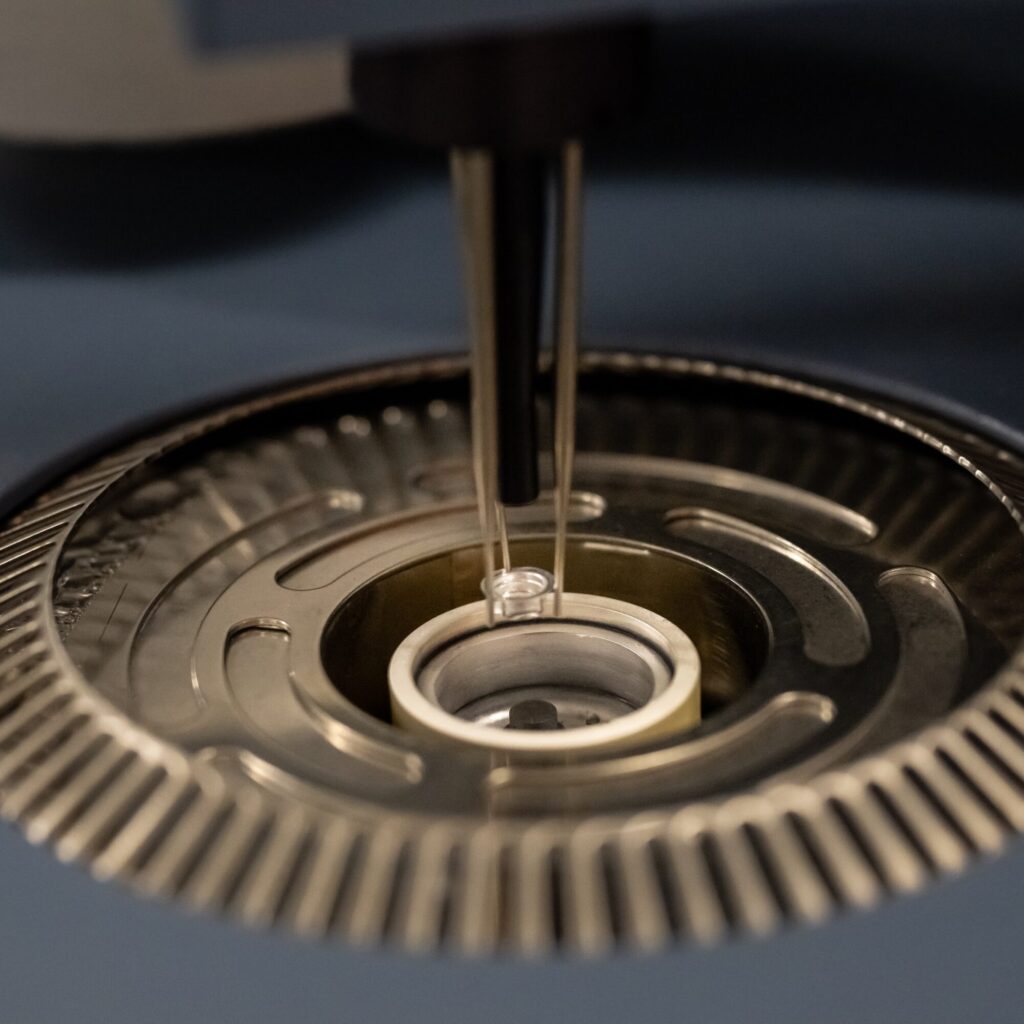

The polymer sample is heated gradually while its weight is continuously recorded. The resulting curve shows:

Each stage provides insight into material composition and stability.

This is where experience matters.

At Kiyo R&D LAB, TGA data is interpreted to explain:

Raw curves alone are meaningless without interpretation.

TGA is often the first test to reveal inconsistency in polymer materials.

It is widely used for:

When mechanical properties look acceptable but TGA curves differ, it’s a warning sign.

TGA is extremely useful when:

By comparing failed samples with reference material, TGA helps identify thermal degradation, filler changes, or volatile loss.

This makes tga analysis of polymers in chennai – Kiyo R&D LAB valuable not only for testing—but for problem solving.

TGA analysis services are relevant for:

If your polymer experiences heat at any stage—processing or service—TGA is not optional.

TGA reports from Kiyo R&D LAB include:

The goal is to help customers make informed decisions, not just archive data.

Polymers rarely fail suddenly. They degrade gradually—until one day they don’t perform as expected.

TGA helps you see that degradation before it becomes a failure.

The tga analysis of polymers in chennai – Kiyo R&D LAB supports manufacturers, researchers, and QA teams by revealing thermal stability, composition, and degradation behavior that other tests cannot show.

If thermal performance matters to your product, TGA is not an advanced option—it’s a necessary one.