Premier Mechanical Testing Services in chennai

That’s no problem! Here is the full blog post on Mechanical Testing Services in India – Kiyo R&D Lab, presented in a clear, human-toned text format, optimized for readability.

Imagine launching a new product – whether it’s an automotive component, a medical device, or a household appliance – only for it to fail prematurely. A cracked casing, a bent lever, or a fatigued joint. This isn’t just a hypothetical nightmare; it’s a real risk for any manufacturer. Why does this happen? Often, it’s a lack of thorough understanding of how materials behave under stress. That’s where Mechanical Testing Services in India – Kiyo R&D Lab steps in as your indispensable partner.

In India’s booming manufacturing sector, from Pune’s automotive hubs to Bengaluru’s aerospace innovators, ensuring product durability, reliability, and safety isn’t just a competitive advantage – it’s a fundamental requirement. Mechanical testing isn’t just about breaking things; it’s about understanding limits, predicting performance, and ultimately, building trust in your products. This comprehensive guide will explore the fascinating world of mechanical testing, its critical importance, the diverse range of tests available, and why Kiyo R&D Lab stands out as a leader in providing top-tier Mechanical Testing Services in India.

At its core, mechanical testing involves subjecting materials, components, or entire products to various forces, loads, and environmental conditions to observe their response. We’re looking for how strong they are, how much they can bend before breaking, how they react to repeated stress, and their overall lifespan under real-world usage.

Think of it as putting your product through a rigorous workout. You want to know if it can lift heavy weights (tensile strength), survive a fall (impact resistance), or endure years of daily use (fatigue testing). Without this crucial data, design decisions are based on guesswork, leading to costly failures, recalls, and reputational damage.

Mechanical Testing Services in India – Kiyo R&D Lab offers a comprehensive suite of tests tailored to various materials and industry needs. Let’s explore some of the most common and critical ones:

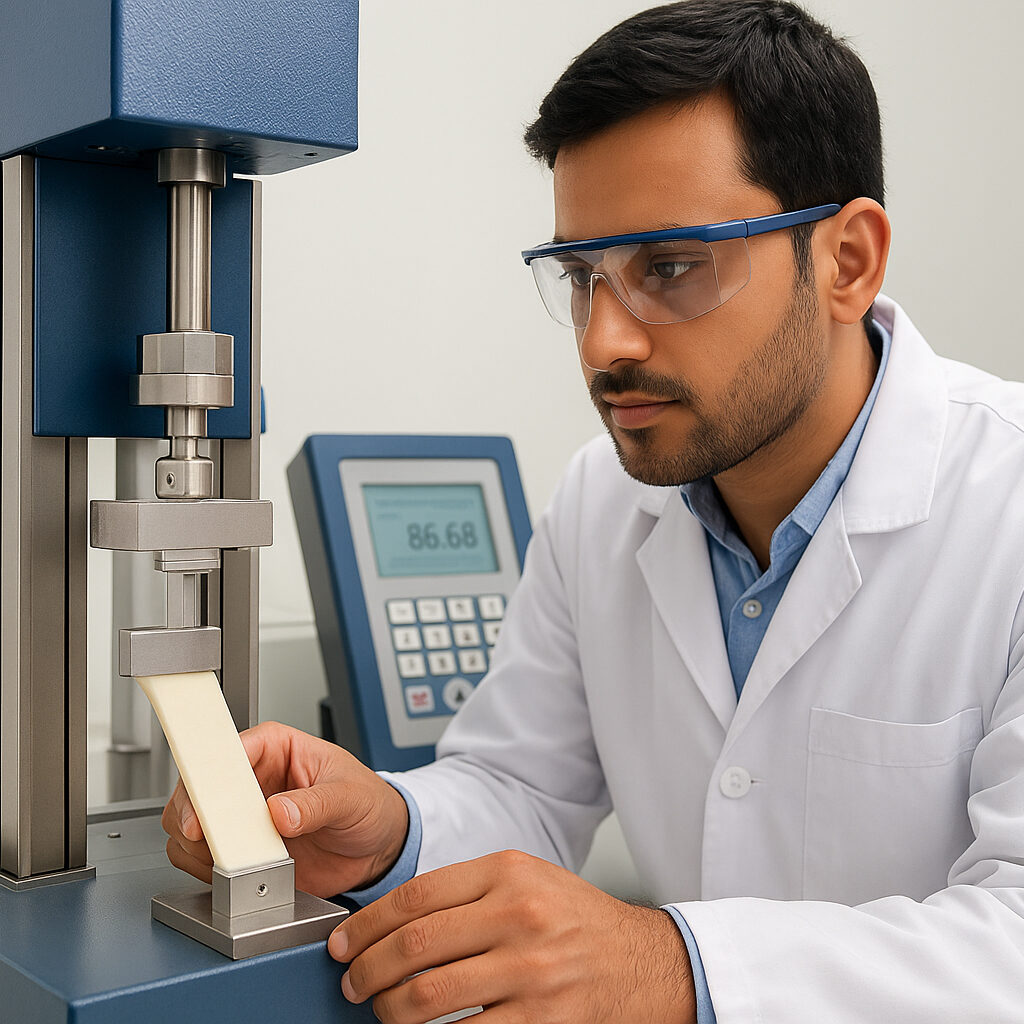

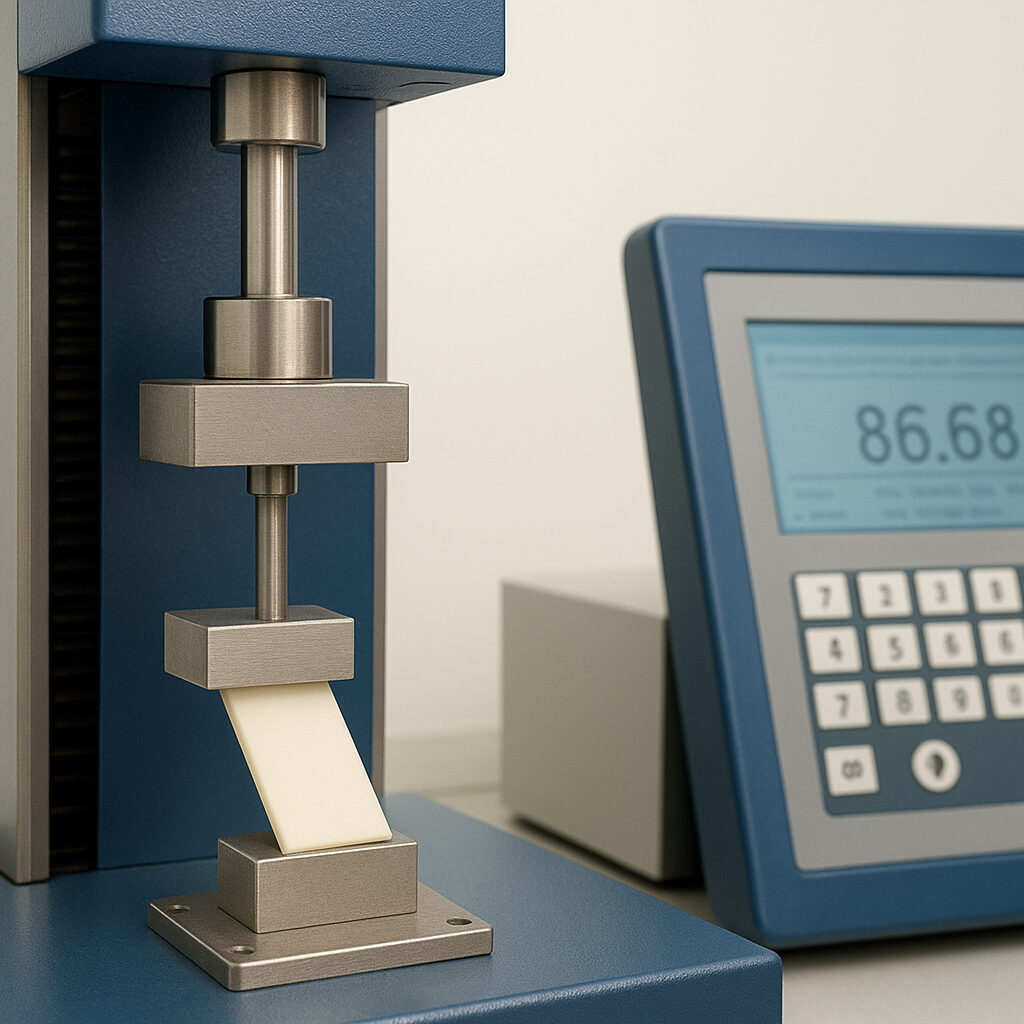

Often considered the most fundamental mechanical test, tensile testing measures a material’s response to a pulling force. A specimen is clamped at both ends and pulled apart at a constant rate until it fractures. The data gathered includes:

Applications: Crucial for metals, plastics, composites, and wires used in structures, cables, and load-bearing components. Essential for automotive chassis, aerospace frames, and construction materials.

The opposite of tensile testing, compression testing measures a material’s ability to withstand forces that try to push it together or crush it. It’s vital for understanding how materials behave under crushing loads.

Applications: Used for concrete, ceramics, foams, and components like engine mounts, packaging, and structural pillars. If your product needs to support weight without deforming, this test is key.

Flexural testing, often a three-point or four-point bend test, measures a material’s resistance to bending or flexing. It’s particularly important for brittle materials or those used in applications where bending stress is common.

Applications: Common for plastics, ceramics, composites, and wood. Think of plastic dashboards, circuit boards, or even bone implants where flexibility under load is critical.

Hardness testing measures a material’s resistance to localized plastic deformation, usually by indentation. Common methods include Rockwell, Brinell, Vickers, and Shore (for plastics/rubbers).

Applications: Essential for tool steels, coatings, gears, and any surface that needs to resist wear, abrasion, or indentation. Impacts durability and lifespan in many components.

Impact testing assesses a material’s toughness – its ability to absorb energy when a sudden, high-speed load is applied, like a hammer blow. It helps determine if a material will shatter or deform under sudden stress.

Applications: Critical for components exposed to sudden forces, such as automotive bumpers, safety helmets, power tool casings, and structural elements in cold environments where materials can become more brittle.

Fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. Fatigue testing simulates years of repeated stress to predict how long a component will last before microscopic cracks grow to failure.

Applications: Indispensable for rotating shafts, aircraft wings, engine components, bicycle frames, and any part that experiences repetitive loading. Failure due to fatigue can be catastrophic.

Shear testing measures a material’s response to forces that act parallel to a surface, causing one part of the material to slide past another. This is particularly relevant for fasteners, adhesives, and composites.

Applications: Crucial for welds, bolts, rivets, and composite laminates where layers need to resist shearing forces. Think of how a bolted joint might fail if the bolts shear off.

Torque testing measures the twisting force required to turn or twist a component, or the resistance of a fastener to loosening. It’s often used for medical devices, fasteners, and assemblies.

Applications: Medical device connections, bottle caps, bolted joints in machinery, and rotary switches. Ensuring a consistent “feel” and reliable connection.

Virtually any industry involved in designing, manufacturing, or using physical products benefits immensely from mechanical testing. Here are just a few:

Choosing the right testing partner is as crucial as the tests themselves. In India, Kiyo R&D Lab has carved a niche as a trusted provider of high-quality, reliable mechanical testing services. Here’s why they are an excellent choice:

Kiyo R&D Lab boasts NABL (National Accreditation Board for Testing and Calibration Laboratories) accreditation. This is not just a fancy certificate; it’s a rigorous, internationally recognized standard (ISO/IEC 17025) that certifies a lab’s competence, impartiality, and consistent operation. When you receive a report from Kiyo, you can be confident that the results are accurate, reliable, and globally accepted. This is paramount for regulatory compliance and export markets.

Modern mechanical testing requires sophisticated machinery – Universal Testing Machines (UTMs), impact testers, hardness testers, fatigue rigs, and more. Kiyo R&D Lab invests heavily in cutting-edge equipment, ensuring high precision, accuracy, and the ability to handle a wide range of materials and test standards.

Even the best equipment is useless without skilled hands and sharp minds. Kiyo’s team comprises experienced engineers and metallurgists who understand the nuances of material behavior, test standards, and data interpretation. They don’t just run tests; they provide insights and consultative support.

From basic tensile strength to complex fatigue analysis, Kiyo R&D Lab offers a vast array of mechanical tests under one roof. This means you can consolidate your testing needs, streamline processes, and get a holistic view of your material or product’s performance.

Consistency is key. Kiyo R&D Lab strictly adheres to national and international testing standards, ensuring that your results are comparable and valid across different contexts and geographies.

Beyond just numbers, Kiyo provides detailed reports that include test parameters, setup details, resulting data curves, and observations. This level of transparency is essential for R&D engineers who need to understand why a material performed the way it did.

Operating right in India means faster turnaround times, lower logistical costs compared to sending samples abroad, and better accessibility for manufacturers across the subcontinent. Kiyo R&D Lab understands the local regulatory landscape and the pressures faced by Indian industries.

The role of a premier testing lab like Kiyo extends far beyond routine quality control (QC). They serve as a critical resource for Failure Analysis. When a product breaks unexpectedly in the field, Kiyo R&D Lab uses specialized mechanical testing combined with microscopy and material characterization to determine the root cause of the failure—was it fatigue, corrosion, manufacturing defect, or poor material choice? This diagnostic service is invaluable for preventing future incidents and protecting brand reputation.

Furthermore, for companies engaged in Material Innovation, Kiyo R&D Lab is a partner in discovery. As you develop new polymer blends, composite laminates, or metal alloys, consistent mechanical data is required at every iteration. Kiyo provides the rigorous testing environment needed to ensure your new material meets the required specifications for the world stage.

Engaging with Kiyo R&D Lab for Mechanical Testing Services in India is a straightforward process designed for maximum efficiency:

Mechanical testing is not a compliance expense; it is a strategic investment in your product’s confidence, safety, and market acceptance. In India, where manufacturing standards are rapidly converging with global best practices, having a reliable, accredited testing partner is no longer a luxury—it’s a necessity.

By choosing Mechanical Testing Services in India – Kiyo R&D Lab, you are opting for precision, global credibility through NABL accreditation, and the consultative expertise required to navigate the complex world of material science.

Don’t risk your reputation on guesswork. Partner with Kiyo R&D Lab today to ensure your components are not just strong, but truly durable, safe, and built to last.