Every material tells the truth—if you test it properly. Failures in products rarely come from “bad luck.” They come from materials that were assumed to perform instead of being verified. This is why materials testing services in Chennai – Kiyo R&D LAB are not just support services; they are risk-control tools for manufacturers, OEMs, exporters, and R&D teams.

At Kiyo R&D LAB, materials testing is approached with one clear objective: give decision-makers reliable data before problems reach the field. No fluff, no exaggerated claims—only measured performance backed by disciplined test methods.

Materials testing is the systematic evaluation of raw materials, semi-finished materials, and finished components to determine their physical, mechanical, thermal, and safety characteristics. It answers practical questions such as:

These questions cannot be answered by datasheets alone. Real materials behave differently once they are processed, molded, cured, or assembled. Testing is how those differences are revealed.

Chennai is a major manufacturing and engineering hub for plastics, rubber, automotive components, electrical products, packaging, and industrial goods. With tight delivery schedules and demanding customers, even small material failures can lead to:

This is where materials testing services in Chennai – Kiyo R&D LAB become essential. Testing provides confidence—not just internally, but also when dealing with customers, auditors, and OEMs.

Kiyo R&D LAB supports a wide range of material categories, including:

Wherever possible, testing is done on actual product samples, not just ideal laboratory specimens. This ensures results reflect real-world performance.

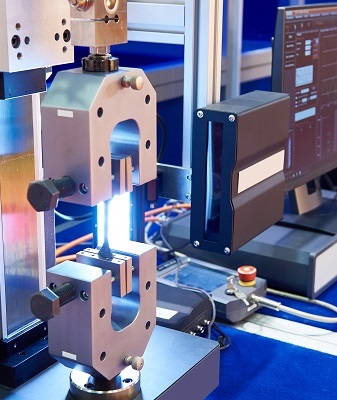

Mechanical properties define whether a material survives loads, impacts, and handling. Tensile, flexural, compression, hardness, and impact testing are commonly used to evaluate strength, stiffness, toughness, and durability.

Materials often fail when exposed to heat, temperature changes, or prolonged environmental conditions. Thermal testing helps understand softening, deformation, or loss of strength under operating conditions.

For polymer-based materials, fire behavior is a critical safety concern. Flammability testing helps classify materials based on how they ignite, burn, and self-extinguish.

Thickness variation, density, and dimensional stability affect fit, function, and consistency. These basic tests often prevent costly assembly and field issues.

Each test is selected based on application relevance, not generic checklists.

A test result is only meaningful when the method is clearly defined. Kiyo R&D LAB conducts materials testing in alignment with recognized standards such as ASTM, ISO, IS, and customer-specific specifications.

Standards-based testing ensures:

Without standards, testing becomes opinion. With standards, it becomes evidence.

Smart engineering teams use materials testing early in development to avoid expensive redesigns later. During product development, testing helps:

Early testing may feel like an added step, but it saves time and money in the long run.

When a product fails in the field, the question is always the same: why? Materials testing helps separate speculation from facts. By examining mechanical behavior, physical changes, and performance shifts, testing supports root-cause analysis and corrective action.

This is especially important when:

Testing provides clarity when assumptions fail.

A materials testing report should do more than list numbers. It should clearly state:

At Kiyo R&D LAB, reports are prepared with clarity and traceability so engineers, quality teams, and customers can understand and act on the results without ambiguity.

Many laboratories can run instruments. Fewer laboratories understand material behavior in real applications.

Kiyo R&D LAB stands out because:

This approach helps clients make confident decisions instead of relying on assumptions.

Materials testing services in Chennai – Kiyo R&D LAB are essential for:

If material performance matters to your business—and it should—testing is not optional.

Materials do not fail randomly. They fail when their limits are unknown or ignored. Materials testing replaces uncertainty with data and risk with clarity. Whether you are developing a new product, qualifying a supplier, or solving a performance issue, materials testing services in Chennai – Kiyo R&D LAB provide the technical foundation needed to move forward with confidence.

In competitive markets, success belongs to companies that test first—and assume nothing.