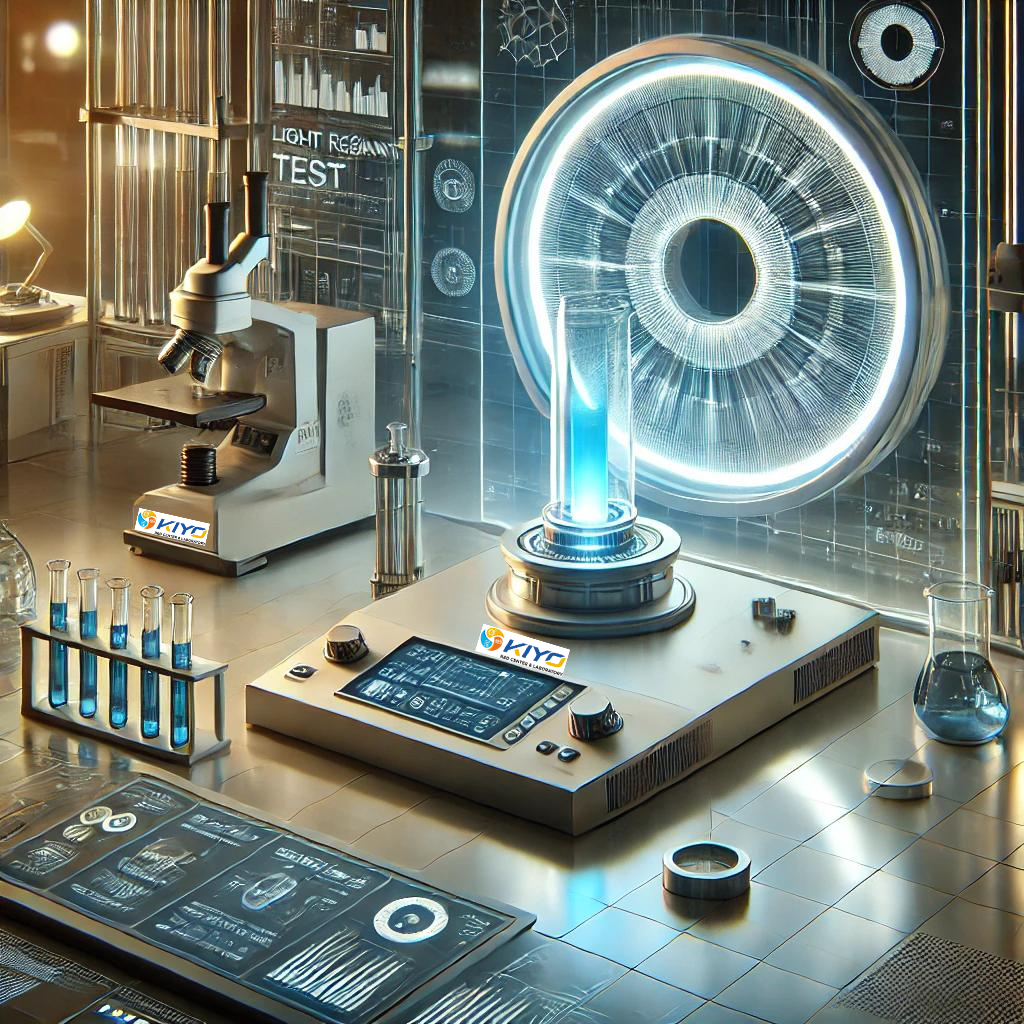

Unveiling Material Durability: The Light Resistance Test (MS 210-05)

In the material testing industry, the Light Resistance Test stands as a cornerstone for assessing the longevity and durability of various materials. At Kiyo R&D Center & Laboratory, we pride ourselves on conducting these tests with the utmost precision and adherence to the MS 210-05 standard, ensuring reliability and quality in every evaluation.

The Light Resistance Test simulates prolonged exposure to light, mimicking the effects of both natural sunlight and artificial light sources. This test is crucial for materials used in environments where light exposure is inevitable, providing essential data on how these materials will endure over time.

The MS 210-05 standard provides a rigorous framework for conducting Light Resistance Tests. This standard ensures that all procedures are meticulously followed, resulting in consistent and accurate test outcomes. By adhering to this standard, we guarantee that our test results are credible and widely accepted.

At Kiyo R&D Center & Laboratory, our Light Resistance Testing process encompasses several critical steps:

Sample Preparation: We meticulously prepare and condition material samples to ensure they accurately represent the final product.

Exposure: Samples are subjected to controlled light sources, simulating natural or artificial lighting conditions as per the MS 210-05 standard. Exposure parameters are carefully managed to ensure precision.

Evaluation: Post-exposure, samples are analyzed for changes in physical properties such as color, strength, and flexibility. We utilize advanced techniques to measure the extent of degradation.

Reporting: Comprehensive reports detailing the material’s performance under light exposure are generated. These reports provide valuable insights for product development and quality assurance.

Engaging in Light Resistance Testing offers numerous advantages:

Improved Product Durability: Understanding material behavior under light exposure allows for enhanced product design and longevity.

Quality Assurance: Regular testing ensures products consistently meet high-quality standards.

Cost Efficiency: Early detection of potential issues can prevent costly recalls and product failures.

Competitive Advantage: Products with superior light resistance can gain a significant market edge.

Kiyo R&D Center & Laboratory is dedicated to providing top-tier testing services, exemplified by our rigorous Light Resistance Testing. Adhering to the MS 210-05 standard, we deliver reliable and accurate results that help our clients create durable, high-quality products.

Explore the comprehensive testing capabilities at Kiyo R&D Center & Laboratory to see how our Light Resistance Testing can benefit your materials and products.

For quotation or visit