Plastics fail in many ways, but impact failure is one of the most visible — and one of the most expensive. A cracked housing, shattered cover, broken pipe, or damaged automotive component often traces back to one overlooked question: How does this plastic behave under sudden force?

That is exactly why the Impact Resistance Test for Plastics – Kiyo R&D LAB is a critical part of material validation, product approval, and quality control.

At Kiyo R&D LAB, impact resistance testing is not treated as a routine checkbox. It is a performance-critical evaluation carried out under NABL-accredited conditions, aligned with ASTM, ISO, and IS standards, to ensure results are reliable, repeatable, and defensible.

Plastics may show excellent tensile or flexural strength, yet still fail catastrophically when subjected to sudden impact. This happens because impact loading is very different from slow, controlled loading.

Impact resistance testing helps evaluate:

Without proper testing, products may pass initial inspections but fail during handling, transportation, installation, or real-world use.

This is where the Impact Resistance Test for Plastics – Kiyo R&D LAB becomes essential.

An impact resistance test measures a plastic material’s ability to withstand a sudden applied force without fracturing. The test simulates real-life conditions such as:

The result indicates how tough or brittle the plastic material is under dynamic conditions.

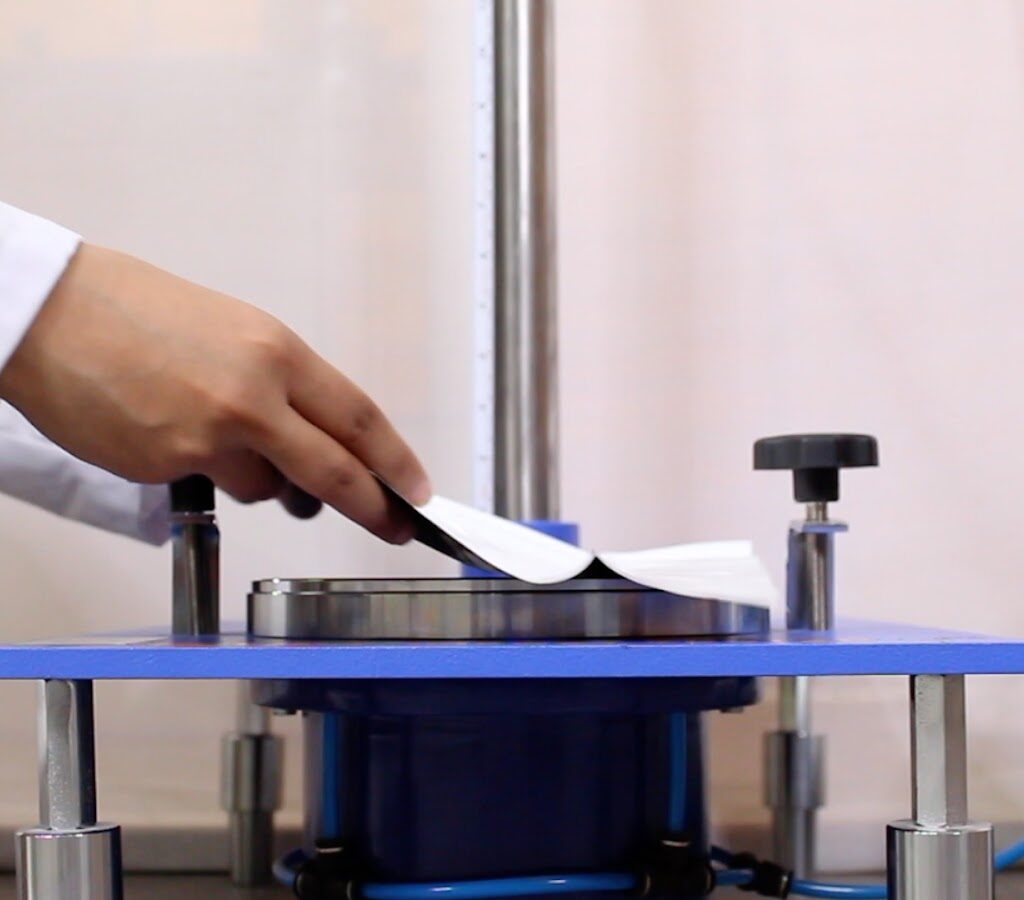

At Kiyo R&D LAB, impact testing is performed using standardized test methods, ensuring data accuracy and comparability.

Depending on application and material type, different impact test methods are used. These include:

Each method provides different insights. Choosing the wrong test can lead to misleading conclusions — which is why guidance matters.

Impact resistance is critical in applications where plastics face sudden forces, such as:

A plastic that fails an impact test may still look fine under static load — until it breaks in service.

At Kiyo R&D LAB, impact resistance testing is conducted under NABL-accredited laboratory conditions, ensuring technical reliability and acceptance.

Our approach includes:

We align testing with relevant ASTM, ISO, and IS standards, depending on material and application.

Impact resistance is not a fixed property. It is influenced by multiple factors, including:

Testing helps identify how these variables affect performance — information that cannot be reliably predicted from datasheets alone.

The Impact Resistance Test for Plastics – Kiyo R&D LAB is essential for:

If your product can be dropped, struck, or mishandled, impact resistance testing is not optional.

Not all test results carry the same credibility.

NABL-accredited impact testing ensures:

This is especially important for:

At Kiyo R&D LAB, every impact test report is structured for technical and audit acceptance.

Clients often approach us after facing:

Impact resistance testing helps identify whether the issue is due to:

This turns assumptions into actionable data.

Let’s be straightforward. Many labs can perform an impact test. Few provide results you can confidently defend.

We focus on engineering relevance, not just numbers.

Engage the Impact Resistance Test for Plastics – Kiyo R&D LAB when:

Early testing saves time, cost, and reputation.

Impact resistance is one of the most critical properties for plastic materials — yet it is often underestimated until failure occurs.

The Impact Resistance Test for Plastics – Kiyo R&D LAB provides manufacturers, designers, and researchers with accurate, NABL-accredited, and practically meaningful data to ensure durability, safety, and performance.

If your plastic product must survive real-world handling, don’t assume it will.

Test it. Validate it. Approve it.

That’s the standard at Kiyo R&D LAB.