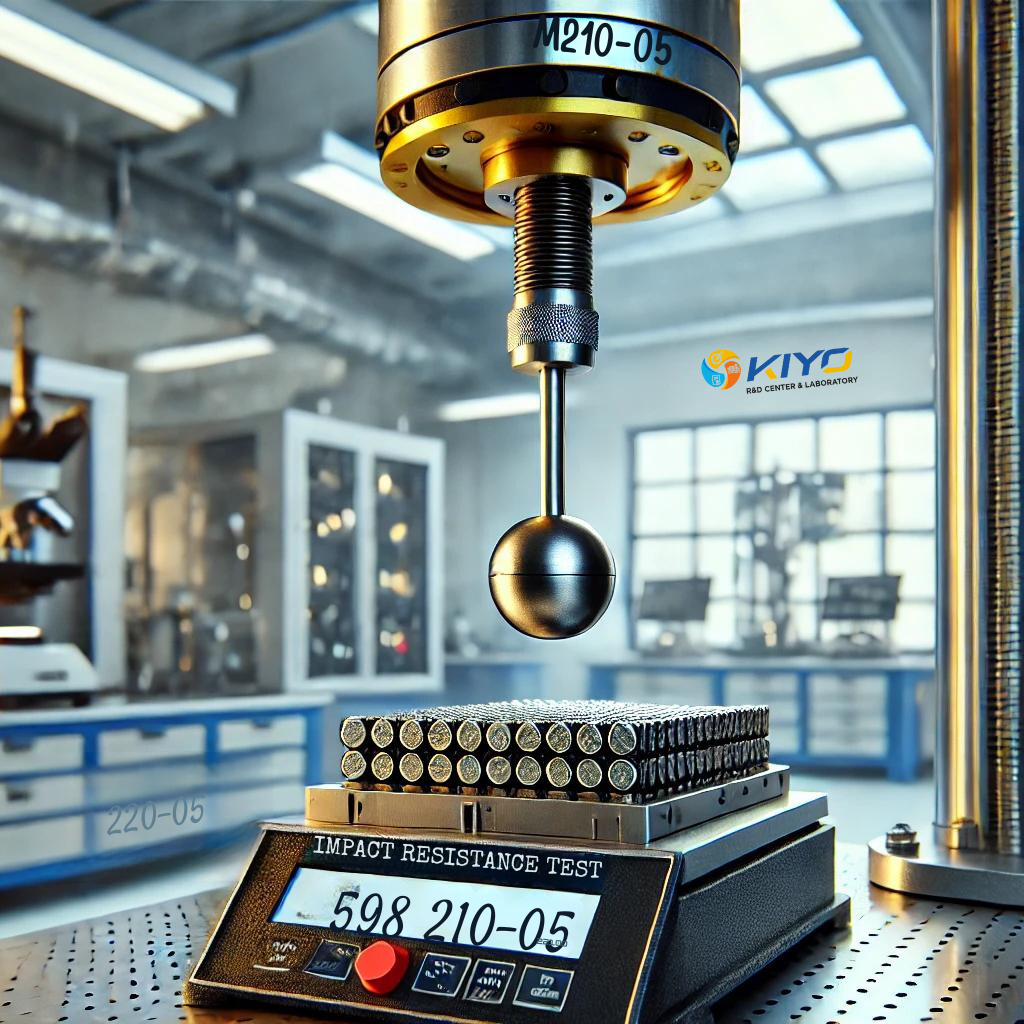

In the realm of materials testing, assessing the ability of materials to withstand sudden impacts is critical. The Impact Resistance Test, as defined by the MS 210-05 standard, is a pivotal procedure that ensures materials can endure real-world mechanical stresses. This blog delves into the intricacies of this test and its significance in various industries.

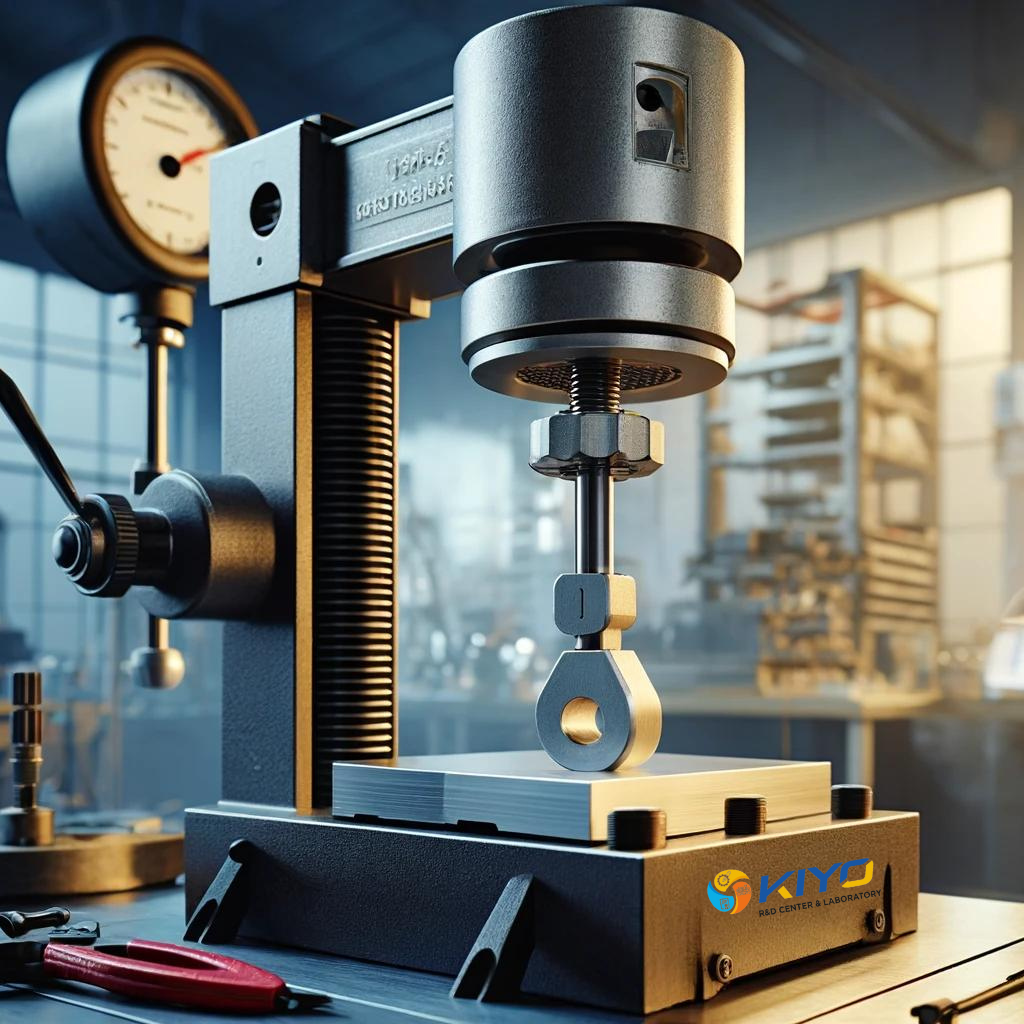

The Impact Resistance Test evaluates a material’s capacity to absorb energy and resist fracture when subjected to a sudden, forceful impact. By simulating real-life scenarios where materials may encounter unexpected blows, this test provides vital data on material toughness and resilience.

The MS 210-05 standard provides a detailed framework for conducting the Impact Resistance Test. Developed by Hyundai, it ensures that the testing process is consistent, reliable, and reproducible. This standard encompasses every aspect of the test, from sample preparation to data analysis, ensuring that the results are accurate and meaningful.

The Impact Resistance Test is essential across a myriad of industries. In the automotive sector, for instance, it helps evaluate the safety and durability of components exposed to impacts during accidents. By understanding a material’s impact resistance, manufacturers can make informed decisions about material selection and product design, enhancing safety and performance.

Recent technological advancements have significantly enhanced the precision and efficiency of impact resistance testing. Modern testing setups now include high-speed cameras, advanced sensors, and sophisticated data analysis tools, providing deeper insights into material behavior under impact conditions.

Adherence to the MS 210-05 standard is vital for ensuring the reliability and consistency of test results. This standard provides a comprehensive guideline that ensures all aspects of the test are conducted meticulously, from the initial preparation of the sample to the final analysis of the data.

The Impact Resistance Test, as outlined by the MS 210-05 standard, is a cornerstone of materials testing. It offers invaluable insights into the durability and toughness of materials, guiding manufacturers in making decisions that enhance product safety and performance.

Understanding and implementing this standard is not only about compliance but also about ensuring that the materials used in products can withstand real-world conditions. As industries continue to innovate, the principles of the MS 210-05 standard remain integral to advancing material science and engineering, ensuring that products are not only safe but also reliable and durable.

For quotation or visit