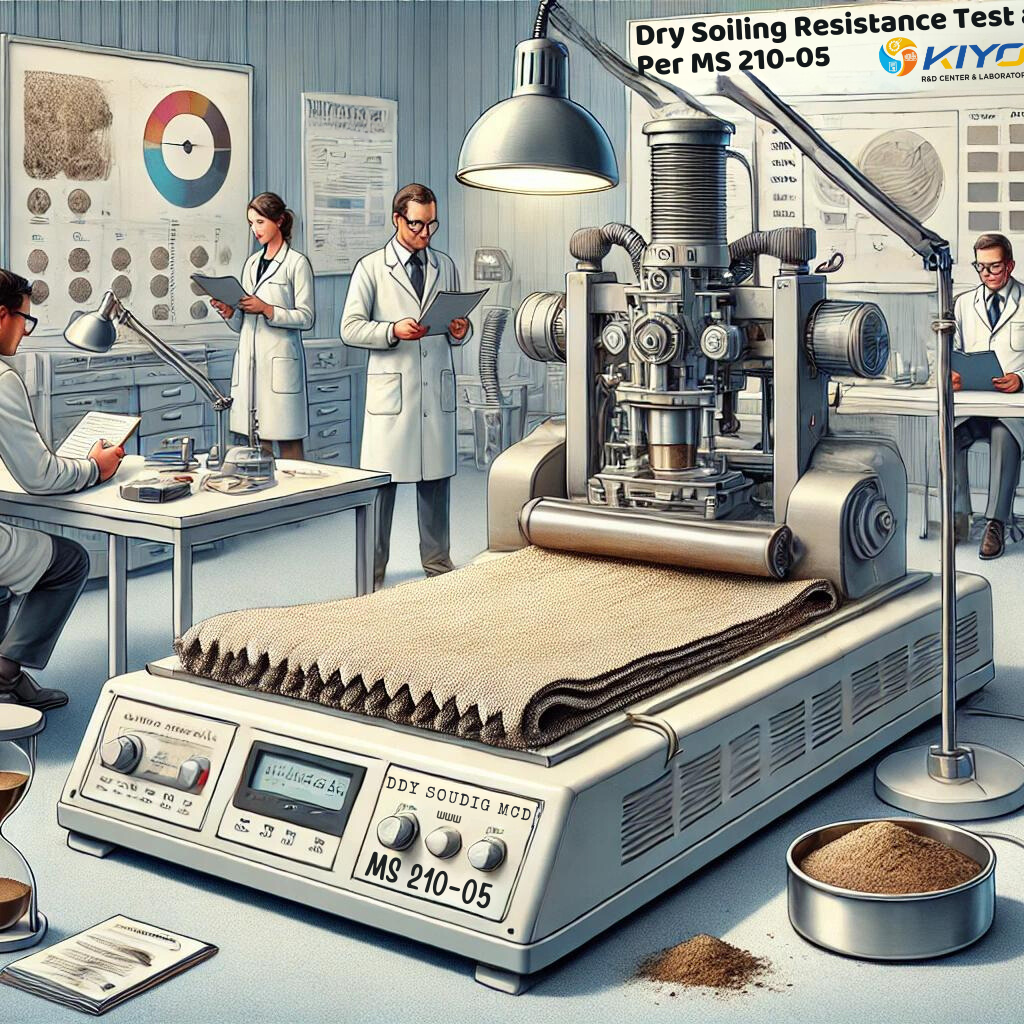

Fabric cleanliness and durability are critical factors in many industries, from automotive to upholstery. The Dry Soiling Resistance Test, guided by the MS 210-05 standard, plays a key role in evaluating a fabric’s resistance to dirt and its ability to remain clean. This test provides essential data that help manufacturers enhance their products’ quality and longevity.

The Dry Soiling Resistance Test measures how well fabrics resist the accumulation of dry soil and dirt. By replicating real-life conditions, this test offers insights into how materials will perform over time, particularly in environments prone to dust and dirt.

The MS 210-05 standard provides a uniform framework for conducting the Dry Soiling Resistance Test. This ensures that the results are reliable, reproducible, and comparable across different testing laboratories. For manufacturers, adhering to this standard is crucial for quality control and product development.

The insights gained from the Dry Soiling Resistance Test are vital for several industries:

Ongoing research aims to refine the Dry Soiling Resistance Test. Innovations include developing new soiling agents that mimic real-world conditions more closely and improving cleaning protocols to better simulate actual use. These advancements help in providing more accurate data for product improvement.

The Dry Soiling Resistance Test, as defined by MS 210-05, is a critical tool for assessing fabric performance in terms of cleanliness and durability. By following this standard, manufacturers can ensure their fabrics meet high-quality standards, leading to better, longer-lasting products.

For quotation or visit