Di-Electric Constant Testing Services in chennai – Kiyo R&D Lab

In the world of high-speed electronics, telecommunications, and power systems, nothing is more critical than the performance of insulating materials. These materials—often polymers, ceramics, or specialized fluids—aren’t just passive barriers against electricity; they are active components that influence how signals travel, how much energy is stored, and ultimately, how safe and efficient a device is.

The key property that governs this behavior is the Di-Electric Constant (also known as relative permittivity). If this value is wrong, or if it shifts due to temperature or humidity, your circuit boards will fail, your cables will leak power, and your high-frequency signals will distort.

For manufacturers in India competing in the global electronics and electrical markets, relying on accurate Di-Electric constant testing services in india – Kiyo R&D Lab is absolutely non-negotiable. We provide the precise electrical characterization needed to secure compliance, guarantee performance, and drive the next generation of high-speed technology.

The Di-Electric Constant ($\epsilon_r$) is a fundamental electrical property of an insulating material.

Think of it this way: when an electrical field is applied, all materials resist the flow of current. But a dielectric material has the ability to store electrical energy by polarizing its internal molecular structure.

The Di-Electric Constant is simply the ratio of electrical energy a material can store compared to a vacuum.

If the measured dielectric constant of a component deviates even slightly from the design specification, the entire device—from a 5G antenna to an automotive sensor—will malfunction.

Dielectric constant testing is far more complex than a simple conductivity check. It provides critical, application-specific data that must be measured precisely under controlled environmental conditions.

In modern computing and telecommunications, signals travel at high frequencies. A material with the wrong dielectric constant slows down the signal propagation speed, causing delays, impedance mismatch, and data corruption. Accurate measurement ensures high-frequency signals are clean and fast.

The capacitance (energy storage capacity) of a capacitor is directly proportional to the dielectric constant of the material sandwiched between its plates. High-precision measurement ensures the capacitor stores exactly the right amount of charge, vital for power regulation in electronics.

While dielectric strength (breakdown voltage) is often tested separately, the dielectric constant provides insight into the efficiency and potential for power loss within the insulating material. A fluctuating constant indicates material instability.

Unlike basic properties, the dielectric constant is highly sensitive to external factors, demanding sophisticated testing:

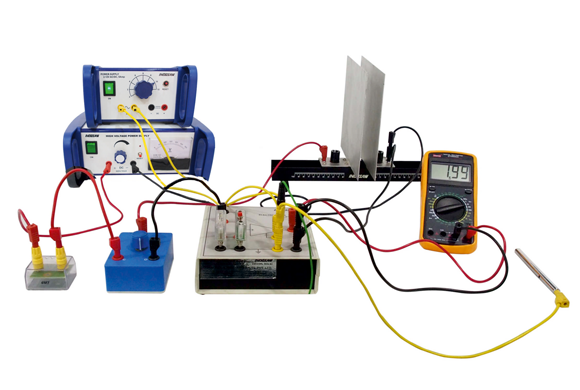

To provide actionable and reliable data, Kiyo R&D Lab uses highly advanced instrumentation, ensuring accurate measurement across varying conditions, typically adhering to standards like ASTM D150 and IEC 62631.

For industries in India requiring precise electrical characterization—from the aerospace sector to mass consumer electronics—Kiyo R&D Lab offers unparalleled reliability:

Our lab operates under the highest international standard of quality management (NABL/ISO 17025). This ensures that our measurement protocols, equipment calibration, and data traceability are globally accepted, giving your products a decisive edge in international markets.

We specialize in polymer materials. Our experts understand how polymer purity, filler content, and moisture absorption directly influence the dielectric constant, allowing us to provide consultative analysis that links electrical performance back to material chemistry.

Kiyo R&D Lab can easily integrate dielectric testing with Thermal Stability Analysis (TGA/DSC) to determine the thermal limits of the insulator, and Environmental Testing to check stability under high humidity, providing a complete performance profile.

We ensure your materials meet the insulating properties required by national and international safety regulations, minimizing the risk of electrical shorts, fire hazards, and liability issues in the final product.

In the era of 5G, electric vehicles, and compact electronics, the performance of dielectric materials is the bottleneck to innovation. Guessing the Di-Electric Constant of your insulator is an unacceptable risk that leads to signal failure, device malfunction, and safety hazards.

By choosing Di-Electric constant testing services in india – Kiyo R&D Lab, you secure verifiable scientific proof that your materials are electrically sound, thermally stable, and ready to power the next generation of technology.

Ready to ensure your insulators won’t fail? Contact Kiyo R&D Lab today to schedule your dielectric property testing.