In the realm of electrical and electronic material testing, conduction resistance testing stands out as a pivotal process. This test is essential for verifying the electrical resistance of materials, ensuring they meet stringent industry standards. This blog will explore the conduction resistance test as per the MS 210-05 standard, outlining its significance and the detailed procedure involved.

Conduction resistance refers to the opposition that a material offers to the flow of electric current. This property is critical for materials used in various electrical applications, influencing their performance, safety, and durability.

The MS 210-05 standard provides a comprehensive framework for conducting resistance testing. It sets forth the requirements and methodologies to ensure that the tests are accurate and reproducible, making it a trusted standard in the industry.

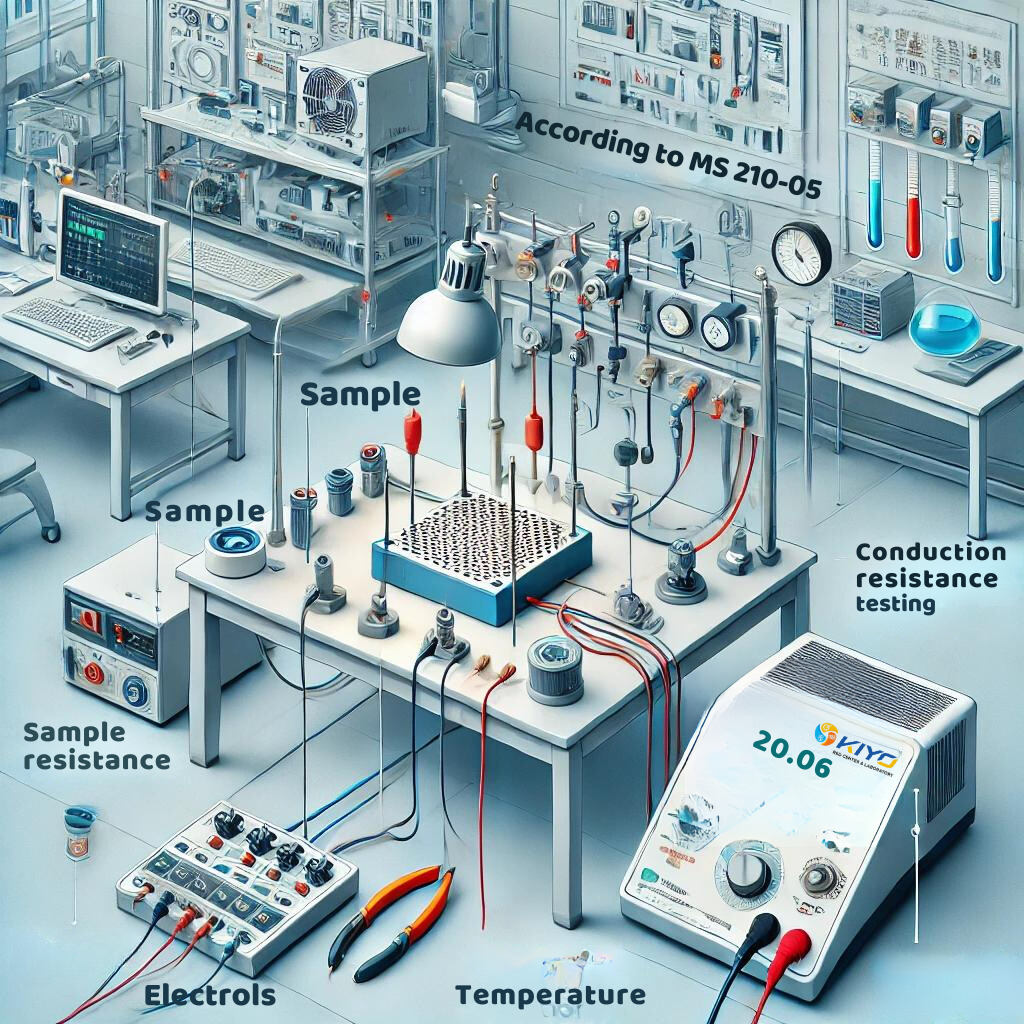

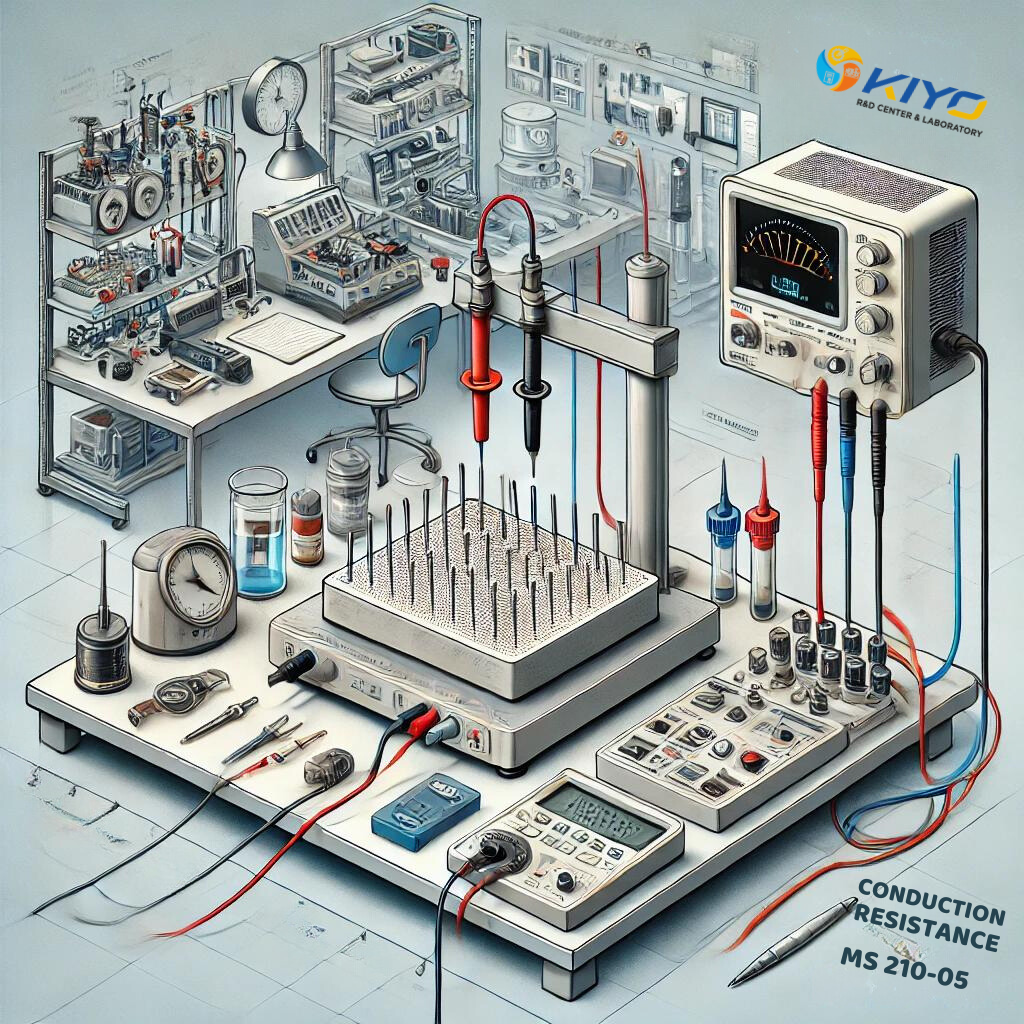

Sample Preparation The initial step involves preparing the material sample according to the guidelines specified in MS 210-05. This includes cutting the sample to precise dimensions and ensuring a clean surface to attach the electrodes.

Electrode Attachment Electrodes are carefully attached to the sample. This step is crucial to minimize contact resistance, which could otherwise affect the accuracy of the results.

Test Setup The testing apparatus consists of a power supply, a multimeter, and a temperature control system. The sample with attached electrodes is connected to this setup. Maintaining a consistent temperature is essential since resistance can vary with temperature fluctuations.

Conducting the Test A specific current is passed through the sample, and the voltage drop across the sample is measured using the multimeter. The resistance is then calculated using the formula: Resistance = Voltage / Current.

Data Analysis The recorded resistance values are compared against the acceptable range defined in MS 210-05. This analysis helps in determining whether the material meets the required standards.

Safety Materials with appropriate resistance levels prevent overheating and electrical failures, thereby enhancing safety.

Performance Ensuring the correct resistance levels in materials contributes to the efficient functioning of electrical systems, reducing energy losses.

Compliance Adhering to MS 210-05 ensures compliance with industry regulations, facilitating market acceptance and reliability.

Conduction resistance testing is utilized across various sectors, including:

Consumer Electronics To ensure the reliability and safety of electronic components.

Automotive Industry For testing wiring and electrical components in vehicles to prevent electrical malfunctions.

Construction For evaluating materials used in building electrical systems to ensure safety and compliance with regulations.

Conduction resistance testing as per the MS 210-05 standard is a fundamental process in verifying the electrical properties of materials. By adhering to this standard, industries can ensure their products are safe, reliable, and efficient.

At Kiyo R&D Center & Laboratory, we are dedicated to providing top-notch materials testing services, including conduction resistance testing. Our state-of-the-art facilities and experienced team ensure that your materials are tested accurately and in compliance with industry standards.

For quotation or visit