Composite materials are built for high performance—lightweight, strong, and engineered for demanding applications. But composites can fail silently if defects like voids, delamination, poor bonding, or incorrect fiber orientation slip into production. That’s why manufacturers and R&D teams choose composite test lab services in Chennai – Kiyo R&D LAB to validate material performance with reliable data.

Composite materials are not like conventional metals or plastics. They are multi-phase systems made from reinforcement fibers (such as glass, carbon, or aramid) combined with a matrix material (polymer, resin, or epoxy). Because of this layered structure, composites behave differently under stress, temperature, and environmental exposure.

Without proper testing, hidden defects such as voids, delamination, fiber misalignment, or poor bonding may go unnoticed until failure occurs. Professional composite test lab services in Chennai – Kiyo R&D LAB help manufacturers detect these issues early and verify that materials meet performance specifications before they reach production or installation.

Composite testing is not limited to one sector. Many industries depend on certified laboratories for accurate evaluation, including:

Aerospace and aviation manufacturers

Automotive component suppliers

Wind energy blade manufacturers

Marine and shipbuilding industries

Construction and infrastructure firms

Research and development organizations

These sectors rely on composite test lab services in Chennai – Kiyo R&D LAB to confirm that materials can withstand real-world mechanical, thermal, and environmental conditions.

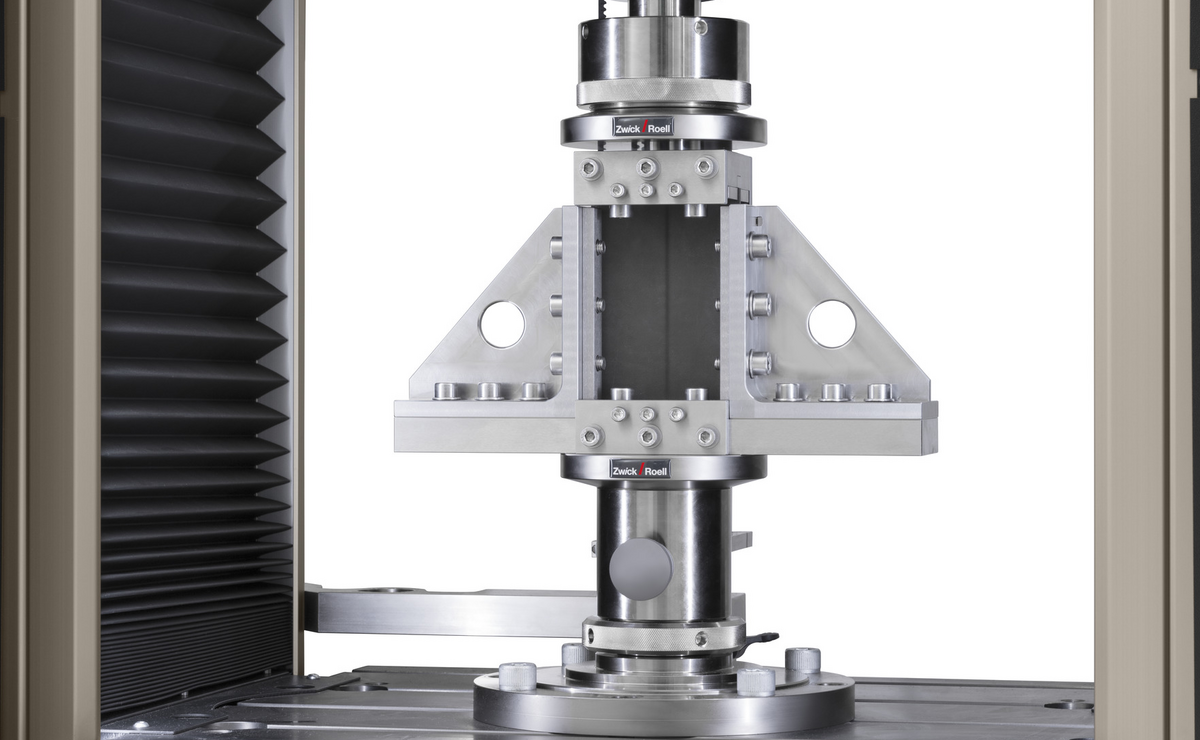

Professional laboratories conduct a wide range of tests to characterize composite properties. These tests help engineers understand material behavior and ensure design safety. Common evaluations include:

Mechanical Testing

Tensile strength, flexural strength, compressive strength, interlaminar shear strength, and impact resistance determine how composites perform under load.

Thermal Testing

Thermal stability, heat distortion temperature, and glass transition temperature testing evaluate performance under temperature variations.

Physical Testing

Density, thickness, moisture absorption, and dimensional stability testing help confirm structural consistency.

Chemical Resistance Testing

Exposure tests determine how composites react to fuels, solvents, oils, or corrosive environments.

Using advanced composite test lab services in Chennai – Kiyo R&D LAB, companies can validate all these parameters through accurate instrumentation and standardized procedures.

Composite testing must follow recognized standards such as ASTM, ISO, or equivalent national standards to ensure results are globally acceptable. Standardized testing allows engineers, clients, and regulatory authorities to compare materials objectively and confirm performance claims.

Choosing certified composite test lab services in Chennai – Kiyo R&D LAB ensures that testing is performed under controlled conditions with calibrated equipment, traceable measurements, and documented procedures. This level of reliability is essential for industries where safety and performance cannot be compromised.

Many manufacturers perform in-house quality checks, but independent testing offers an extra layer of credibility. Third-party results provide unbiased verification, which is particularly valuable during audits, certifications, or client approvals.

Advantages of professional composite test lab services in Chennai – Kiyo R&D LAB include:

Objective and independent validation

High-precision measurement systems

Expert interpretation of results

Detailed technical reports

Acceptance by consultants and regulatory bodies

Independent testing builds trust with customers and demonstrates a commitment to quality and transparency.

One of the biggest benefits of composite testing is failure prevention. A component might look perfect visually but still contain structural weaknesses. Laboratory analysis can reveal:

Micro-cracks or internal defects

Weak bonding between layers

Fiber orientation issues

Improper curing or resin distribution

Inconsistent material composition

With composite test lab services in Chennai – Kiyo R&D LAB, these problems can be identified early, allowing engineers to correct manufacturing processes and avoid costly product failures.

Testing is not only for quality control—it also drives innovation. R&D teams rely on laboratory data to develop new composite formulations, optimize fiber orientation, and improve mechanical performance. Accurate testing allows researchers to compare different materials and select the best option for specific applications.

By using professional composite test lab services in Chennai – Kiyo R&D LAB, product developers gain reliable data that supports design decisions, performance validation, and material optimization.

Chennai has become a major hub for engineering, automotive, aerospace, and industrial manufacturing. As product complexity increases, so does the demand for advanced material testing. Companies prefer specialized laboratories that offer dedicated expertise in composite analysis rather than general testing facilities.

Trusted composite test lab services in Chennai – Kiyo R&D LAB provide technical guidance along with testing, helping clients interpret results and make informed engineering decisions. This partnership approach adds value beyond simple testing.

Quality assurance is more than a checklist—it is a continuous process that ensures consistency from raw material to finished product. Composite materials must meet strict tolerance limits, mechanical strength requirements, and environmental resistance standards.

With professional composite test lab services in Chennai – Kiyo R&D LAB, manufacturers can confirm that each batch of material meets required specifications. This reduces product recalls, improves reliability, and enhances brand reputation.

Testing is recommended at multiple stages of the product lifecycle:

During raw material evaluation

During prototype development

Before mass production

During production quality checks

After environmental exposure studies

During failure analysis

Using composite test lab services in Chennai – Kiyo R&D LAB at these stages ensures consistent monitoring and performance verification.

As industries push toward lighter, stronger, and more sustainable materials, composites will continue to evolve. New fiber technologies, hybrid laminates, and nano-reinforced systems require increasingly sophisticated testing methods. Laboratories equipped with advanced instruments and technical expertise will play a vital role in validating these next-generation materials.

Professional composite test lab services in Chennai – Kiyo R&D LAB are positioned to support this future by providing accurate testing, detailed analysis, and technical insights that help industries innovate confidently.

Kiyo R&D Center & Laboratory – Advanced Materials Centre, Chrompet, Chennai

Kiyo R&D Center & Laboratory – Innovation Centre, Oragadam, Chennai

Phone: 090876 86986

Website: www.kiyorndlab.com

For quotation or visit