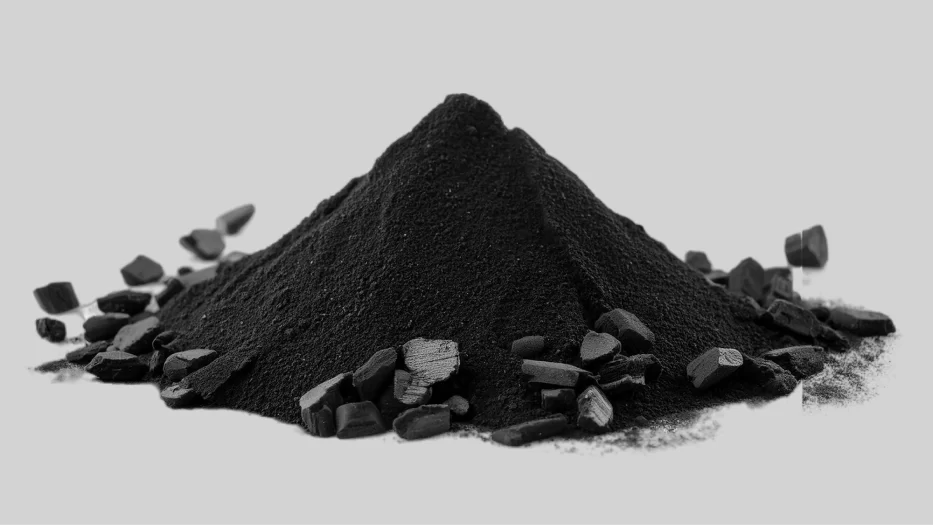

Carbon black content testing is a laboratory procedure used to determine the percentage of carbon black present in a material, usually polymer or rubber-based. The test is typically performed by controlled thermal decomposition or furnace methods that separate carbon black from the base polymer, allowing precise measurement.

With professional carbon black content test services in Chennai – Kiyo R&D LAB, manufacturers can verify whether their materials meet specified standards and formulation requirements. This test is particularly important for products exposed to sunlight, weather, or mechanical stress.

Carbon black is not just a colorant—it is a functional additive that improves performance characteristics. Accurate content ensures:

UV protection and weather resistance

Improved tensile strength

Enhanced abrasion resistance

Better thermal stability

Longer product life

Using carbon black content test services in Chennai – Kiyo R&D LAB, manufacturers can confirm that materials contain the correct amount of additive to achieve desired performance levels.

Many industries depend on carbon black content testing for quality assurance and compliance. These include:

Plastic pipe manufacturers

Cable and wire insulation producers

Automotive component manufacturers

Rubber product industries

Packaging manufacturers

Polymer compound suppliers

In these sectors, carbon black content test services in Chennai – Kiyo R&D LAB help verify formulation consistency and ensure that materials meet customer specifications and technical standards.

Carbon black testing provides valuable information about material composition and quality. The test typically evaluates:

Percentage of carbon black in sample

Uniformity of dispersion

Consistency between batches

Compliance with formulation limits

Presence of impurities or residual ash

With carbon black content test services in Chennai – Kiyo R&D LAB, companies receive accurate data that supports production control, product approval, and technical validation.

Carbon black content must be tested according to recognized standards such as ASTM, ISO, or other industry specifications. Standardized methods ensure results are reliable and comparable across laboratories and projects.

Choosing professional carbon black content test services in Chennai – Kiyo R&D LAB ensures testing is performed using calibrated equipment, controlled procedures, and trained analysts. This guarantees traceable results suitable for audits, certifications, and customer acceptance.

Accurate carbon black measurement provides several advantages for manufacturers and engineers:

Prevents product failures caused by incorrect formulation

Improves product durability and performance

Ensures compliance with industry standards

Reduces material wastage and rework

Builds customer confidence in product quality

Using carbon black content test services in Chennai – Kiyo R&D LAB, companies gain reliable insights that help them maintain consistent product quality.

Carbon black content testing is useful at multiple stages of production and product development:

During raw material verification

During formulation development

Before mass production

During routine quality control

During failure analysis

By performing carbon black content test services in Chennai – Kiyo R&D LAB at these stages, manufacturers can detect issues early and correct them before products reach the market.

Testing can reveal hidden problems that may not be visible through visual inspection alone. These include:

Incorrect additive dosing

Poor dispersion of carbon black

Batch inconsistencies

Contamination in raw materials

Improper processing conditions

Professional carbon black content test services in Chennai – Kiyo R&D LAB help identify these issues quickly, allowing manufacturers to adjust their process and maintain quality standards.

A reliable laboratory plays a crucial role in ensuring accurate testing results. Proper carbon black testing requires controlled heating systems, precision weighing instruments, and experienced technicians who understand polymer behavior.

With carbon black content test services in Chennai – Kiyo R&D LAB, clients benefit from:

Advanced analytical equipment

Skilled technical professionals

Accurate and repeatable measurements

Structured test reports

Technical guidance and interpretation

These factors ensure that test results are trustworthy and suitable for engineering decisions and compliance documentation.

Research and development teams depend on composition analysis when developing new polymer formulations. Carbon black content data helps engineers optimize additive levels to achieve desired mechanical strength, UV resistance, and durability.

Using carbon black content test services in Chennai – Kiyo R&D LAB, R&D teams gain reliable data that supports product improvement and innovation.

Chennai is a major manufacturing hub with strong industries in automotive, plastics, cables, construction, and engineering. As competition increases, companies must maintain strict quality standards to remain competitive.

Specialized laboratories offering carbon black content test services in Chennai – Kiyo R&D LAB provide precise measurement, fast reporting, and technical expertise. This allows manufacturers to ensure consistent quality and meet customer requirements.

As materials become more advanced and applications more demanding, additive control will become even more critical. Modern products require exact formulations to achieve performance targets, especially in industries such as infrastructure, automotive, and electronics.

Laboratories providing carbon black content test services in Chennai – Kiyo R&D LAB are equipped to support these evolving needs by delivering accurate testing and detailed analysis.

For quotation or visit