Every material looks strong—until it fails. Strength, stiffness, ductility, toughness, and durability are not opinions. They are measurable properties. That’s why mechanical testing services in Chennai – Kiyo R&D LAB play a critical role in product development, quality control, and failure prevention.

Mechanical testing is not just a laboratory requirement. It is the backbone of safe design, reliable manufacturing, and regulatory compliance. Without proper mechanical testing, materials are approved based on assumptions—and assumptions are expensive.

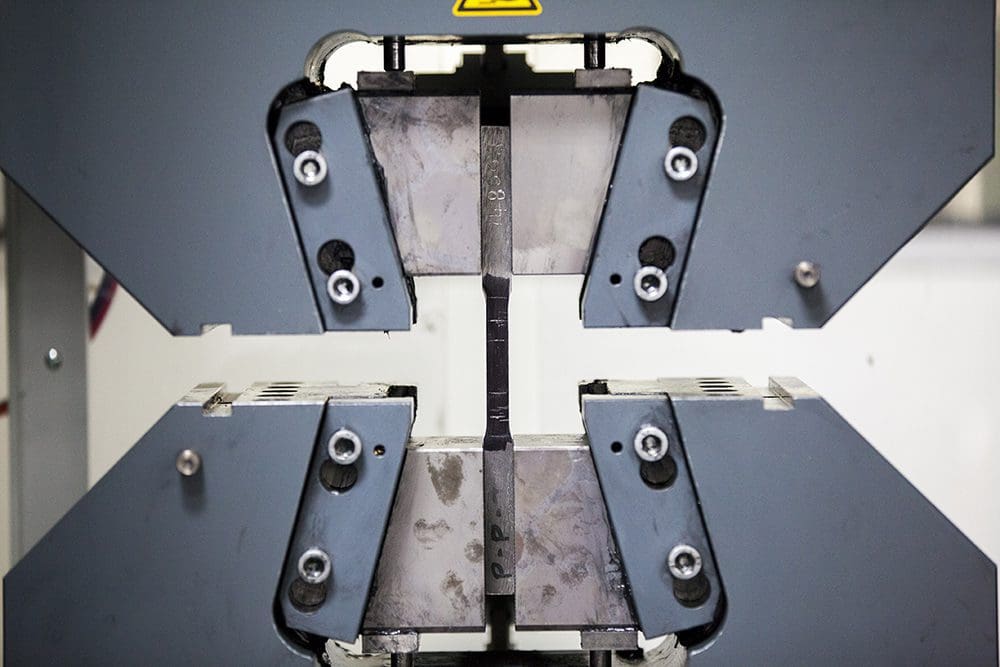

Mechanical testing evaluates how a material behaves when subjected to forces such as tension, compression, bending, impact, and fatigue. These tests simulate real-world conditions to determine whether a material or component can safely perform its intended function.

With mechanical testing services in Chennai – Kiyo R&D LAB, materials are tested under controlled conditions to generate quantifiable, repeatable, and standard-compliant data.

In simple terms:

Mechanical testing tells you how and when a material will fail—before it happens in service.

Skipping mechanical testing doesn’t save time or money. It only delays failure.

Mechanical testing helps to:

If your product carries load, stress, vibration, or impact, mechanical testing is mandatory—not optional.

Mechanical testing services in Chennai – Kiyo R&D LAB cover a wide range of tests for plastics, rubber, metals, composites, and engineering materials.

Tensile testing determines:

This test answers a fundamental question: How much force can the material handle before it breaks?

Compression testing evaluates how materials behave under crushing loads.

Used for:

This test is critical for components designed to carry weight or resist deformation.

Flexural testing measures:

It is especially important for plastics, composites, and beams that experience bending during service.

Impact testing evaluates a material’s ability to absorb sudden energy without fracturing.

Commonly used for:

Impact resistance often determines whether a product fails safely—or catastrophically.

Hardness testing helps assess:

Different hardness methods are used depending on the material type.

Some failures occur not due to overload, but due to repeated stress over time.

Fatigue testing helps understand:

Mechanical testing services in Chennai – Kiyo R&D LAB are not limited to one material category.

Testing is performed for:

Each material requires different grips, test speeds, specimen preparation, and interpretation—which is where expertise matters.

Testing at Kiyo R&D LAB is carried out in alignment with:

Following standards is not paperwork—it ensures results are comparable, defendable, and audit-ready.

Automotive components face:

Mechanical testing ensures parts meet:

This is why OEMs and vendors rely on mechanical testing services in Chennai – Kiyo R&D LAB for validation and quality control.

Many student projects fail to stand out because testing is superficial.

Kiyo R&D LAB supports:

Students gain real-world testing exposure, not just theoretical knowledge.

Mechanical testing is not about running a machine and printing numbers. It’s about choosing the right test, preparing the specimen correctly, and interpreting results accurately.

Mechanical testing services in Chennai – Kiyo R&D LAB are trusted because of:

This lab focuses on engineering decisions, not just test execution.

Ignoring mechanical testing leads to:

Most of these issues are preventable with proper testing at the right stage.

Materials don’t fail randomly. They fail when their limits are misunderstood or ignored.

If you need reliable data, confident design decisions, and compliance-ready documentation, mechanical testing services in Chennai – Kiyo R&D LAB provide the clarity you need.

Because in engineering, what you don’t test is what eventually fails.